Er-containing high-niobium Ti-Al intermetallic compound material and preparation method thereof

An intermetallic compound, high niobium technology, applied in the intermetallic compound material, Er-containing high niobium TiAl intermetallic compound material and its preparation field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

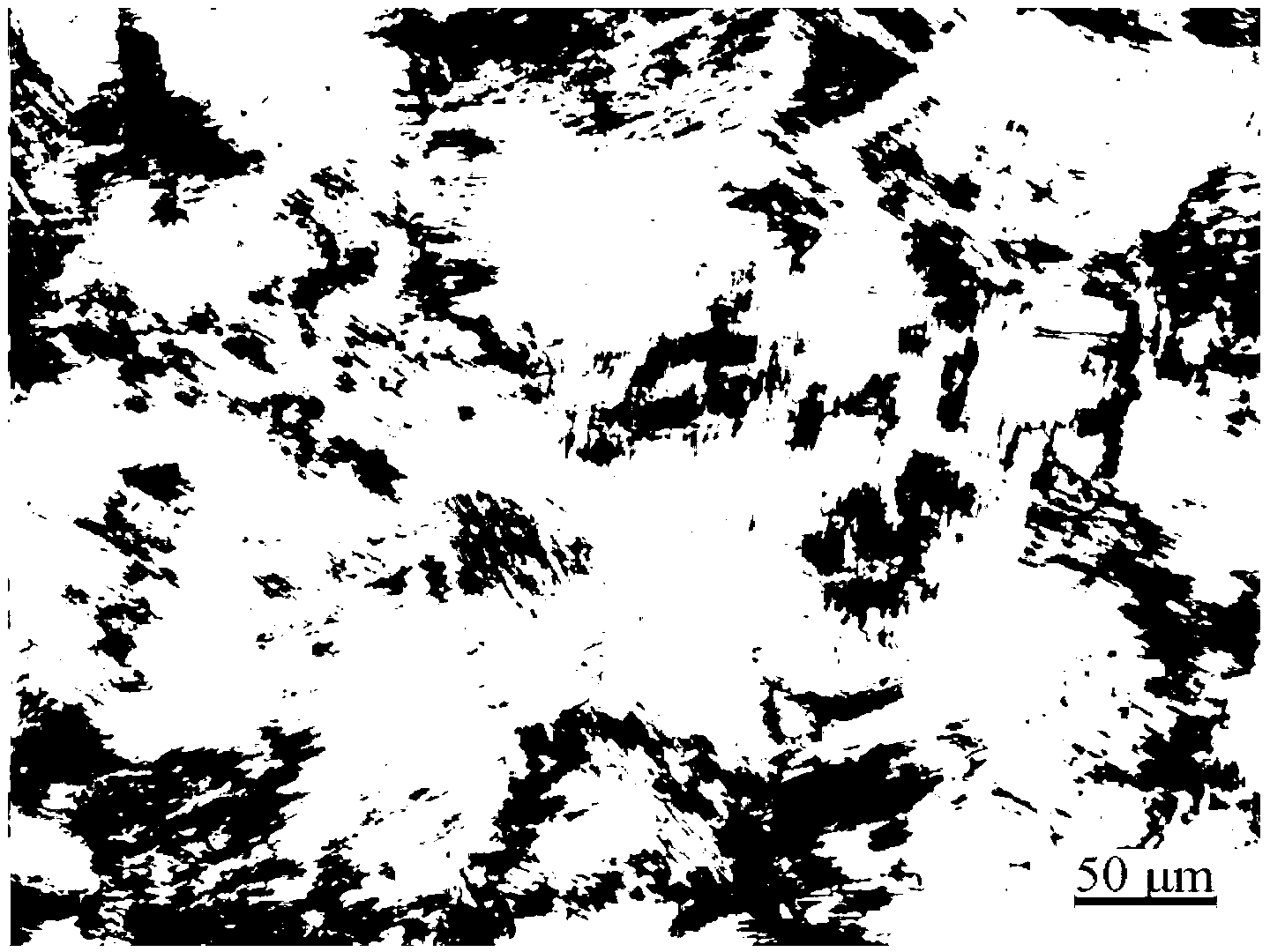

Image

Examples

Embodiment 1

[0017] The preparation of the Er-containing high-niobium TiAl intermetallic compound material of the present embodiment is realized through the following steps: 1. Take the following raw materials: sponge titanium, high-purity aluminum, aluminum-niobium master alloy and aluminum-erbium master alloy, wherein Ti45.8at.% , Al46at.%, Nb8at.%, Er0.2at.%; 2. Layer the raw materials weighed in step 1 into the water-cooled copper crucible vacuum induction melting furnace, and the layers from bottom to top are sponge titanium layer, high Pure aluminum layer, aluminum niobium master alloy layer, aluminum erbium master alloy layer and sponge titanium layer; 3. Before melting, preheat the metal mold at a temperature of 350 ℃, and vacuum the water-cooled copper crucible vacuum induction melting furnace to 3.0× 10 -3 mbar; 4. Increase the smelting power of the water-cooled copper crucible vacuum induction melting furnace to 180kw at a growth rate of 10kw / min, then stop increasing the power,...

Embodiment 2

[0020] (1) Weigh the following raw materials: titanium sponge, high-purity aluminum, aluminum-niobium master alloy and aluminum-erbium master alloy; wherein the molar percentages of Al, Nb, Er and Ti elements are controlled to be 41%~46% of Al, 8~10% Nb, 0.2-0.4% Er and the rest Ti and impurities;

[0021] (2) Add the raw materials weighed in step (1) into the water-cooled copper crucible vacuum induction melting furnace in layers, and the layers from bottom to top are sponge titanium layer, high-purity aluminum layer, aluminum-niobium master alloy layer, aluminum Erbium intermediate alloy layer and sponge titanium layer; before melting, the metal mold is preheated to 300~350℃, and the water-cooled copper crucible vacuum induction melting furnace is evacuated to 2.0~3.0×10 -3 mbar, increase the melting power of the water-cooled copper crucible vacuum induction melting furnace to 160-180kw at a growth rate of 5-10kw / min, then stop increasing the power, and then melt at a consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com