Spherical hollow mesoporous carbon shell and preparing method thereof

A hollow mesoporous and spherical technology, which is applied in the field of spherical hollow mesoporous carbon shells and its preparation, can solve the problems of hollow carbon spheres such as wall thickness and depression, and achieve the effects of various shapes, broad application prospects, and easy-to-obtain templates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

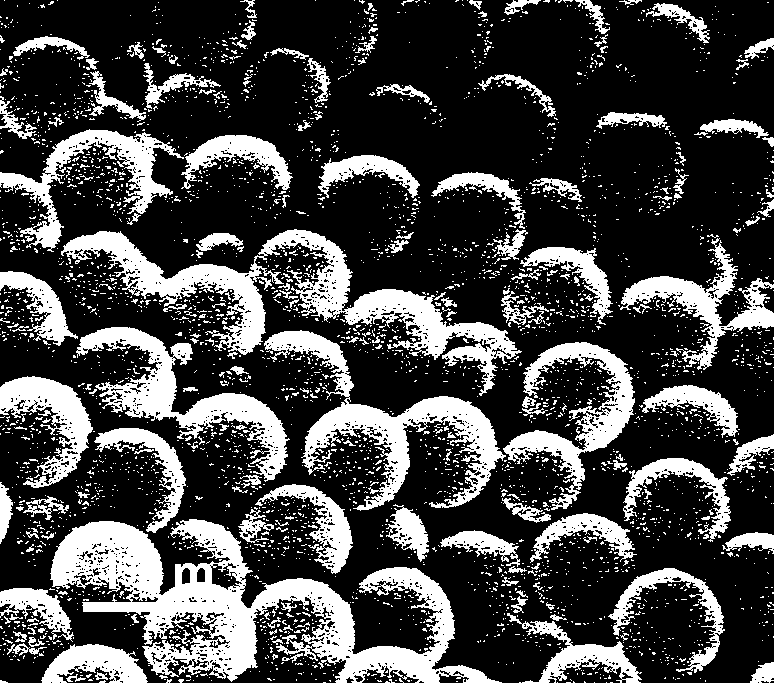

[0025] Embodiment 1: The spherical hollow mesoporous carbon shell is prepared by using the following raw materials and methods.

[0026] (1) Add 2g of triblock copolymer P123 into 20g of absolute ethanol, stir to dissolve; then take 4.5g of spherical calcium carbonate with a particle size of 80nm and mix with the above solution for 30h to obtain a mixed solution.

[0027] (2) Take 2g of phloroglucinol formaldehyde resin and add 10ml of absolute ethanol, stir evenly; then mix and stir with the above mixture; after stirring, carry out polymerization reaction at room temperature for 12 hours, and then carry out repolymerization reaction in an oven at 100°C for 24 hours , to obtain powdered polymer.

[0028] (3) Put the powder polymer into the tube furnace under N 2 Carry out high-temperature carbonization under the atmosphere, and the carbonization process is programmed from room temperature to 800 ° C, and maintained for 1 hour to obtain carbides.

[0029] (4) Put the carbide ...

Embodiment 2

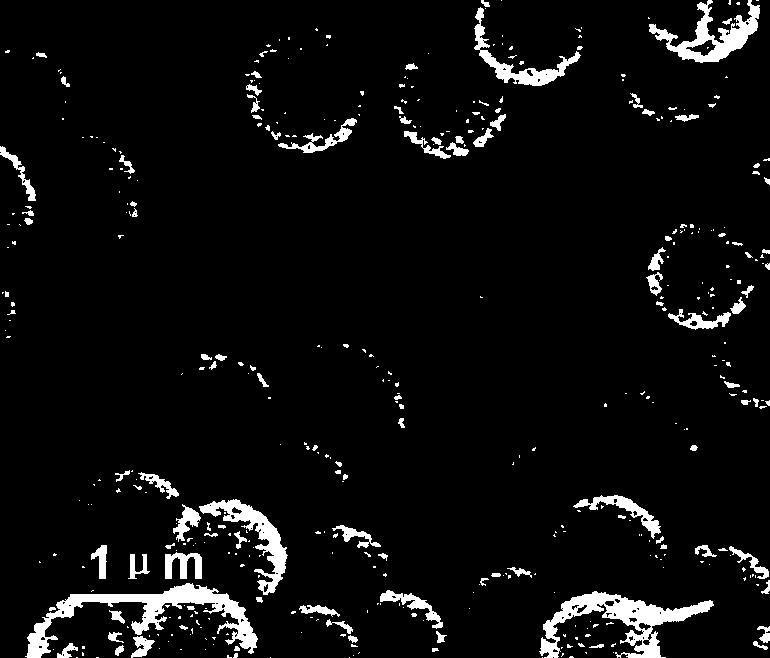

[0030] Embodiment 2: The spherical hollow mesoporous carbon shell is prepared by using the following raw materials and methods.

[0031] (1) Add 2g of triblock copolymer P123 into 20g of absolute ethanol, stir to dissolve; then take 4g of spherical calcium carbonate with a particle size of 500nm and mix with the above solution for 30h to obtain a mixed solution.

[0032] (2) Take 3g of resorcinol formaldehyde resin, add 10ml of absolute ethanol, stir well; then mix and stir with the above mixture; after stirring, carry out polymerization reaction at room temperature for 6 hours, and then carry out repolymerization reaction in an oven at 120°C 36h, the powder polymer was obtained.

[0033] (3) Put the powdered polymer into a tube furnace for N 2 Carbonize at high temperature to 1000°C and maintain for 3 hours to obtain carbonized products.

[0034] (4) Put the carbonized substance into 2mol·L -1 Dissolve and remove calcium carbonate in dilute hydrochloric acid; then wash rep...

Embodiment 3

[0035] Embodiment 3: The spherical hollow mesoporous carbon shell is prepared by using the following raw materials and methods.

[0036] (1) Add 0.5g of triblock copolymer F127 to 20g of absolute ethanol, stir to dissolve; then take 12.5g of spherical calcium carbonate with a particle size of 500nm and mix with the above solution for 28h to obtain a mixed solution.

[0037] (2) Take 2.5g of bisphenol A formaldehyde resin solution, add 10ml of absolute ethanol, stir well; then mix and stir with the above mixture; after stirring, carry out polymerization reaction at room temperature for 20h, and then carry out repolymerization in an oven at 140°C After 12 hours of reaction, powder polymer was obtained.

[0038] (3) Put the powdered polymer into a tube furnace for N 2 Carbonize at high temperature to 800°C and maintain for 6 hours to obtain carbonized products.

[0039] (4) Put the carbonized substance into 1mol·L -1 Calcium carbonate was dissolved and removed in dilute acetic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com