Flexible composite ceramic membrane with low temperature closed-cell performance and good dimensional stability

A dimensionally stable, composite ceramic membrane technology, used in electrical components, circuits, battery pack components, etc., can solve the problems of inconvenient handling, high membrane cost, cumbersome operation, etc., to achieve comprehensive electrochemical performance improvement, good size Stability, Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

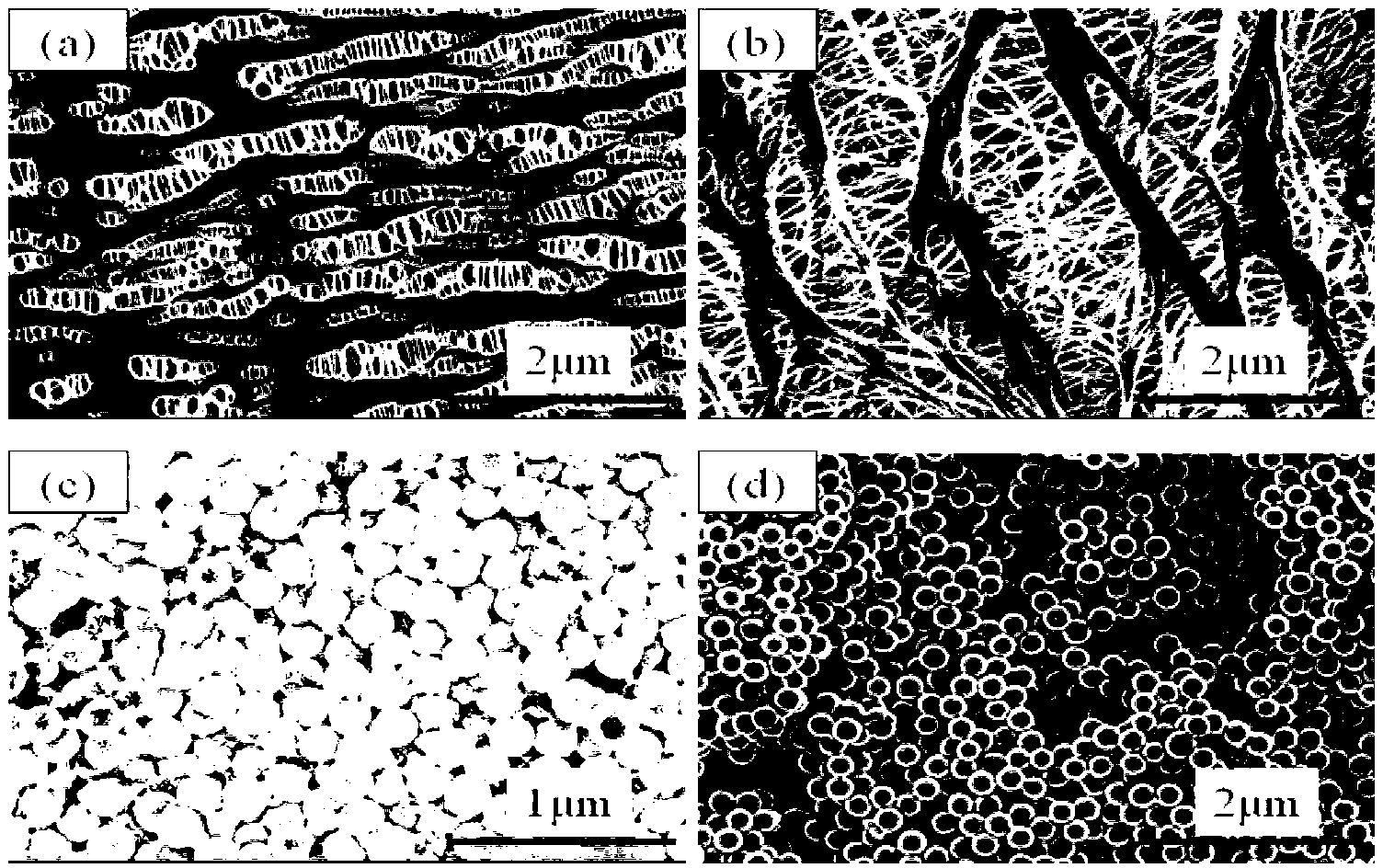

[0073] A flexible composite ceramic membrane with low-temperature closed-cell performance and good dimensional stability, prepared by the following method:

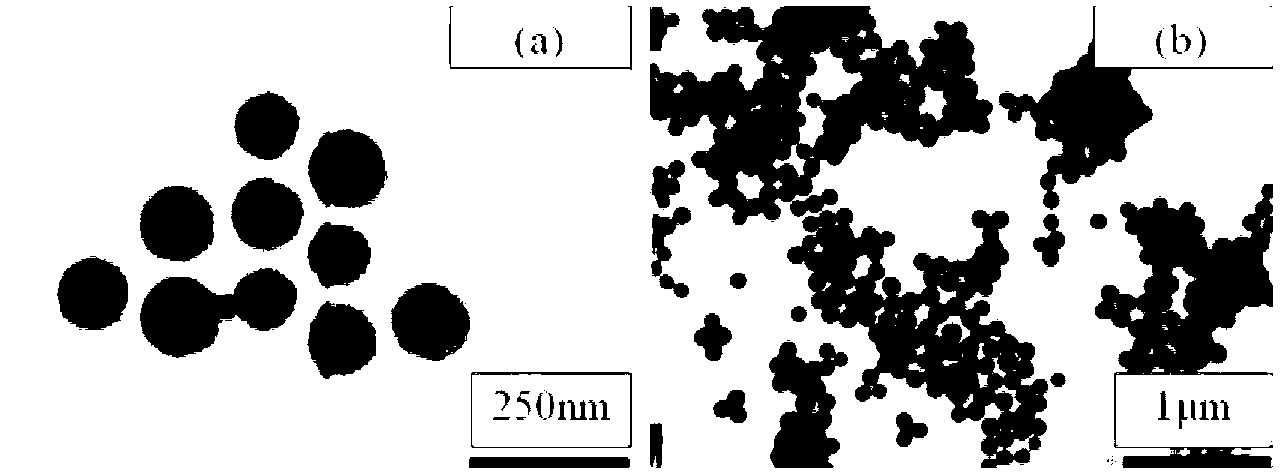

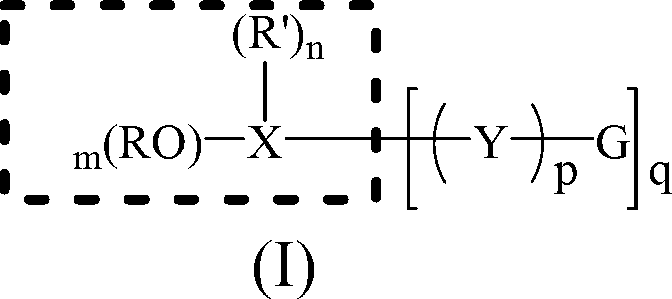

[0074] According to the mass ratio, 1 part of 2-(3,4-epoxycyclohexyl)-ethyltrimethoxysilane (ECTS) (see formula 1 for structure), 1 part of diphenylsilanediol (DPSD) (see formula for structure) 2) Mix 10 parts of polyethylene glycol dimethyl ether and 0.002 parts of barium hydroxide, and react at 80° C. for 4 hours. Disperse 8 parts of 200nm silicon dioxide in ethanol, then add it to the above system, continue to react at 80°C for 8 hours, cool to room temperature, add 0.005 parts of photoinitiator diaryliodonium salt, remove under reduced pressure part of ethanol to obtain the coating solution. Coat the coating solution on both surfaces of the PP porous membrane (thickness 25 μm, porosity 55%) with hydroxyl groups with a wire bar coater, control the thickness of the composite membrane at about 40 μm, and cure it under a...

Embodiment 2

[0099] A flexible composite ceramic membrane with low-temperature closed-cell performance and good dimensional stability. The preparation method is except that methyl hexahydrophthalic anhydride is selected as the curing agent when curing, and thermal curing is selected as the curing method instead of light curing. Other operations All with embodiment 1 with raw material.

[0100] The Gurley value, liquid absorption rate and thermal shrinkage rate of the flexible composite ceramic membrane prepared in this example with low-temperature closed-cell performance and good dimensional stability were measured. The prepared composite membrane was used as a diaphragm, assembled into a battery, and the closed cell temperature of the composite diaphragm was measured. Test method is the same as embodiment 1.

Embodiment 3

[0102] A flexible composite ceramic membrane with low-temperature closed-cell performance and good dimensional stability. Its preparation method is to replace the PP porous membrane with hydroxyl groups on the surface with PP porous membranes with amino groups on the surface, and use heat curing instead of adding any catalyst during curing. Except for photocuring, other operations and raw materials are the same as in Example 1.

[0103] The Gurley value, liquid absorption rate and thermal shrinkage rate of the flexible composite ceramic membrane prepared in this example with low-temperature closed-cell performance and good dimensional stability were measured. The prepared composite membrane was used as a diaphragm, assembled into a battery, and the closed cell temperature of the composite diaphragm was measured. Test method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com