A kind of preparation method of lithium-ion battery diaphragm

A lithium-ion battery and separator technology, applied in the field of preparation of lithium-ion battery separators, can solve the problems of decreased composite fastness, interface debonding, and impact on product air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

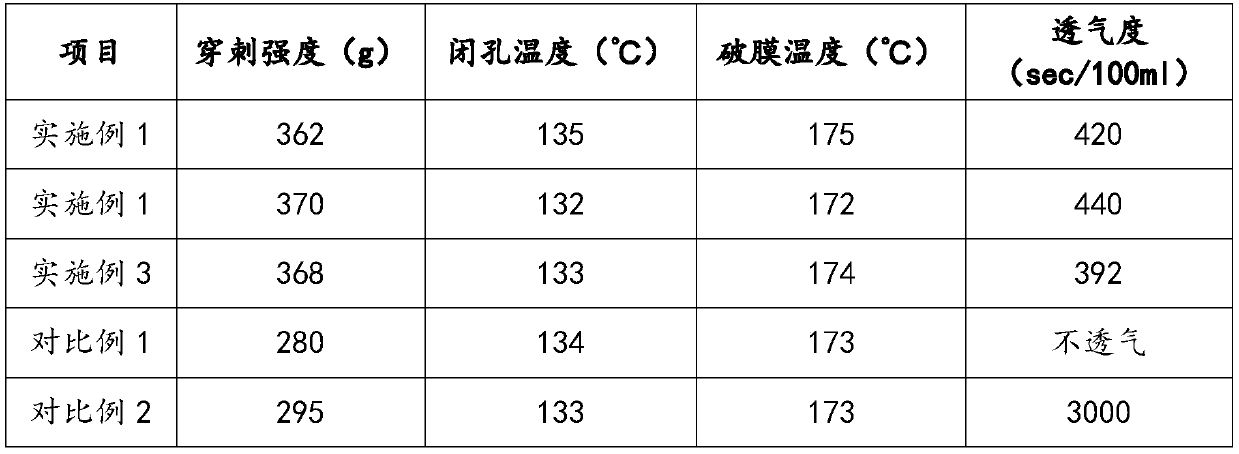

[0020] The embodiment of the present invention discloses a preparation method of a lithium-ion battery diaphragm, which includes the following steps: mixing polypropylene, the first alloy material and the first auxiliary additive, stirring, and then adding to the first extruder to melt and plasticize, to obtain The first melt; polyethylene, the second alloy material and the second auxiliary additive are mixed, stirred, and then added to the second extruder for melting and plasticizing to obtain the second melt; the first melt and the second The melt die is extruded, and an intermediate film is formed after casting treatment. The intermediate film uses the second melt as the middle layer and the first melt as the surface layer; the intermediate film is annealed under slight tension. Stretched to form a lithium-ion battery separator.

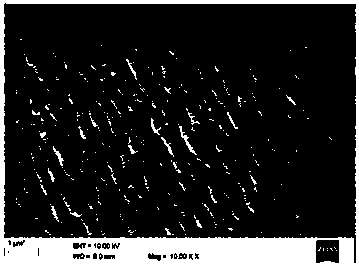

[0021] The lithium ion battery prepared by the present invention is a three-layer PP / PE / PP microporous membrane, the thickness is preferably 5-40...

Embodiment 1

[0035] This example provides a high-performance lithium-ion battery microporous diaphragm, the main raw material of which is polypropylene, polyethylene, alloy material (PP / PE mass percentage is 7:3), and the auxiliary additive is antioxidant 1010 (four [ Methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester), the thickness of the microporous membrane is 16 μm, and the porosity is 37%. The content of main resin polypropylene and polyethylene is 90%, wherein the mass percentage of polypropylene: polyethylene is 4:3, the mass percentage of alloy material is calculated as 5%, and the content of antioxidant is calculated as 5% by mass percentage.

[0036] The method for preparing the described microporous membrane comprises the steps of:

[0037] 1. Stir the main polypropylene, 1 / 2 weight alloy material and 1 / 2 weight auxiliary additives through a high-speed mixing mixer under certain conditions, the stirring speed is 3000rpm, and the stirring time is 30mi...

Embodiment 2

[0046] This example provides a high-performance lithium-ion battery microporous diaphragm, the main raw material of which is polypropylene, polyethylene, alloy material (PP / PE mass percentage is 6:4), and the auxiliary additive is antioxidant 1010 (four [ Methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester), the thickness of the microporous membrane is 16 μm, and the porosity is 37%. The content of polypropylene and polyethylene in the main resin is 85%, wherein the mass percentage of polypropylene: polyethylene is 4:3, the mass percentage of alloy material is calculated as 10%, and the content of antioxidant is calculated as 5% by mass percentage.

[0047] The method for preparing a microporous membrane for a high-performance lithium-ion battery is basically the same as in Example 1, except that in the sixth annealing process, the annealing temperature is changed to 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| membrane rupture temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com