Shallow seabed symmetric audio communication cable and manufacture method thereof

An audio communication and symmetrical technology, which is applied in the direction of submarine cables, cable/conductor manufacturing, and twisted/quad-stranded cables. Signal transmission impact and other issues, to achieve excellent physical and mechanical properties, high mechanical strength, stable communication signal transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

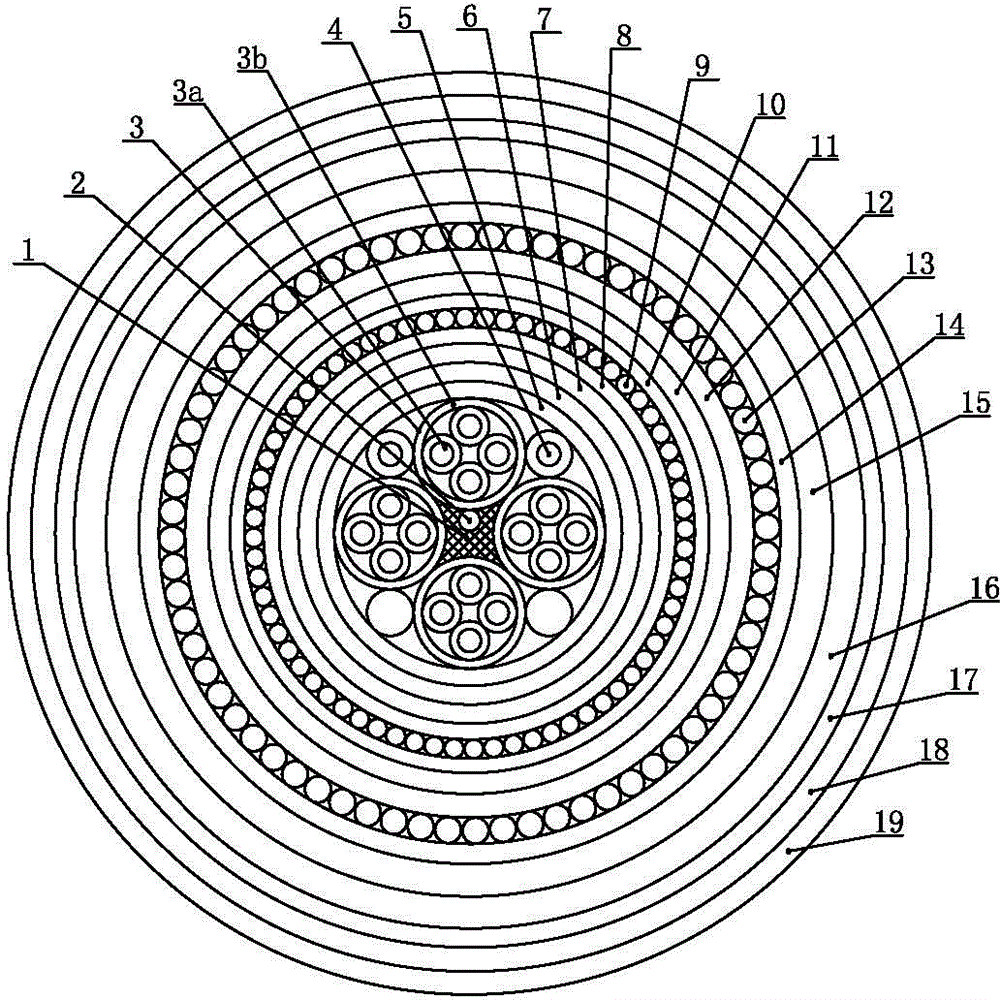

[0019] The shallow sea submarine symmetrical audio communication cable of the present invention is manufactured according to the following steps in sequence: (1) A high-pressure polyethylene insulating layer with a nominal thickness of 1.0 mm is extruded on a solid circular copper conductor with a diameter of 1.2 mm to form an insulating core 3a; The nominal thickness of the high-pressure polyethylene insulation layer is 1.0mm and the minimum thickness is not less than 90% of the nominal thickness, the maximum thickness is not greater than 110% of the nominal thickness, and the diameter deviation measured by any vertical section does not exceed 10%.

[0020] (2) Twisting four insulated wire cores 3a of different colors into a star stranded group 3, and the two on the diagonal form a working pair; wrap different color ribbons 3b outside the star stranded group, and then combine the four The star-quad groups are arranged tangentially in a circular array on the outer periphery of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com