Method for preparing rare-earth-tungsten electrode material

An electrode material, rare earth tungsten technology, applied in the field of metallurgical smelting, can solve the problems of incomplete and uniform sintering state, unbalanced sintering temperature and time, unstable powder sintering process, etc. The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

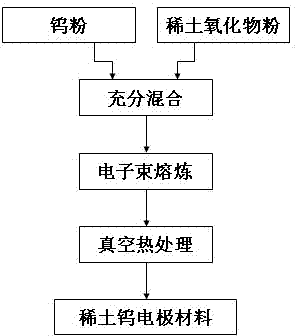

[0025] Such as figure 1 As shown, a brief flow process of a preparation method of a rare earth tungsten electrode material is:

[0026] The first step of powder mixing: mix tungsten powder with an average particle size of 0.5 μm and a purity of 99.1% and yttrium oxide powder with an average particle size of 2 μm and a purity of 99.2%, and ball mill for 4 hours to make it fully and uniformly mixed to obtain a mixed powder, oxidized The quality of yttrium powder accounts for 4% of mixed powder total mass;

[0027] The second step of hot press molding: the mixed powder is hot press molded at a temperature of 1700 ° C and a pressure of 25 MPa for 3 hours to obtain a tungsten-yttrium oxide block mixture;

[0028] The third step of electron beam melting: put the tungsten-yttrium oxide block mixture in the crucible of the electron beam melting furnace, evacuate to below 0.0045Pa, turn on the electron gun with a high voltage of 32kV and a beam current of 400mA for melting, melting fo...

Embodiment 2

[0031] Such as figure 1 As shown, a brief flow process of a preparation method of a rare earth tungsten electrode material is:

[0032] The first step of powder mixing: mix tungsten powder with an average particle size of 1 μm and a purity of 99.2% with zirconia powder with an average particle size of 4 μm and a purity of 99.3%, and ball mill it for 1 hour to make it fully and uniformly mixed to obtain a mixed powder, zirconia The quality of the powder accounts for 1% of the total mass of the mixed powder;

[0033] The second step of hot press molding: the mixed powder is hot press molded at a temperature of 1800 ° C and a pressure of 30 MPa for 1 hour to obtain a tungsten-zirconia block mixture;

[0034] The third step of electron beam melting: put the tungsten-zirconia block mixture in the crucible of the electron beam melting furnace, evacuate to below 0.0042Pa, turn on the electron gun with a high voltage of 30kV and a beam current of 600mA for melting, melting for 20min,...

Embodiment 3

[0037] The first step of powder mixing: mix tungsten powder with an average particle size of 3 μm and a purity of 99.1% with lanthanum oxide powder with an average particle size of 6 μm and a purity of 99.2%, and ball mill for 2 hours to fully and uniformly mix to obtain a mixed powder, zirconia The quality of powder accounts for 7% of the total mass of mixed powder;

[0038] The second step of hot press molding: the mixed powder is hot press molded at a temperature of 1900 ° C and a pressure of 35 MPa for 4 hours to obtain a tungsten-zirconia block mixture;

[0039] The third step of electron beam smelting: put the tungsten-zirconia block mixture in the crucible of the electron beam smelting furnace, evacuate to below 0.0038Pa, turn on the electron gun with a high voltage of 28kV and a beam current of 700mA for smelting, smelting for 10min, and solidify After cooling, turn the tungsten-zirconia alloy ingot over, and then melt it for 10 minutes at a high voltage of 28kV and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com