Stuffing for capacitor and preparation method thereof

A technology for capacitors and fillers, applied in the field of capacitors, can solve the problem that the electrical properties and physical and chemical properties of fillers cannot meet the needs, and achieve the effects of excellent physical and chemical properties, simple production process, and easy large-scale application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

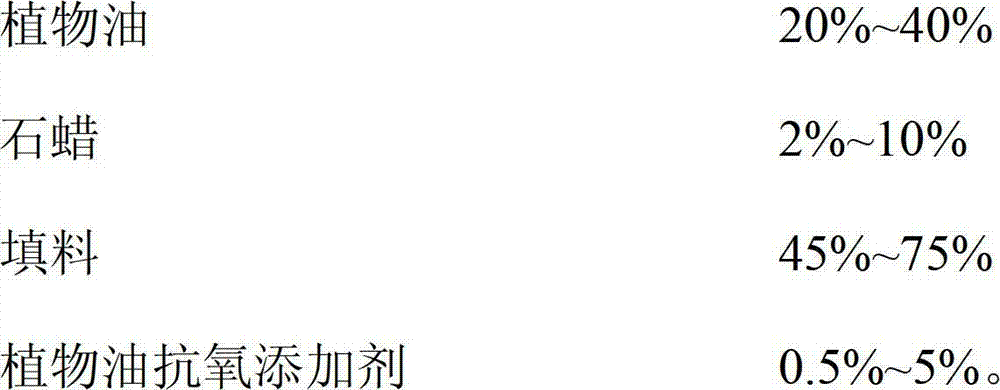

Method used

Image

Examples

Embodiment 1

[0056] (1) Heat up 20g of castor oil to 80°C, vacuum-treat for 15 hours, then break the vacuum, add 1g of tocopherol, 1g of ferulic acid and 1g of tea polyphenols, and vacuum-treat again at 120°C for 8 hours;

[0057] (2) Heat 2g of paraffin to 70°C to melt it;

[0058] (3) mixing the vegetable oil obtained in step (1), the melted paraffin wax obtained in step (2) and 75 g of microsilica powder with a particle size of 0.2 to 1 μm to obtain a filler for capacitors;

[0059] (4) Use the filling material obtained in step (3) for the filling of CBB65 aluminum shell capacitors.

[0060] Table 1 shows the test results of fillers for capacitors.

Embodiment 2

[0062] (1) Heat 40g of rapeseed oil to 120°C, vacuum for 8 hours, then break the vacuum, add 2g of BHA and 3g of BHT, and vacuum again at 80°C for 16 hours;

[0063] (2) Heat 10g of paraffin to 120°C to melt it;

[0064] (3) mixing the vegetable oil obtained in step (1), the melted paraffin wax obtained in step (2), and 45 g of talcum powder with a particle size of 0.1 to 0.4 μm to obtain a filler for capacitors;

[0065] (4) Use the filling material obtained in step (3) for the filling of CBB65 aluminum shell capacitors.

[0066] Table 1 shows the test results of fillers for capacitors.

Embodiment 3

[0068] (1) Heat 30g of corn oil to 100°C, vacuum treatment for 10 hours, then break the vacuum, add 0.5g of sesamol, and vacuum again at 110°C for 9 hours;

[0069] (2) Heat 4g of paraffin to 110°C to melt it;

[0070] (3) Mix the vegetable oil obtained in step (1), the melted paraffin wax obtained in step (2), 60g of talc powder with a particle size of 0.5~0.7μm, and 5.5g of mica powder with a particle size of 0.6~0.8μm to obtain a capacitor with filler;

[0071] (4) Use the filling material obtained in step (3) for the filling of CBB65 aluminum shell capacitors.

[0072] Table 1 shows the test results of fillers for capacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com