Special glass fiber reinforced nylon 6 material for water gauges and water pumps and preparation method of nylon 6 material

A water pump and water meter technology, applied in the field of nylon 6 materials, can solve the problems of low dry and low temperature impact strength, poor adhesion and dispersibility, poor comprehensive product performance, etc., to improve adhesion and dispersibility, and poor toughness. Reduced, no floating fiber effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

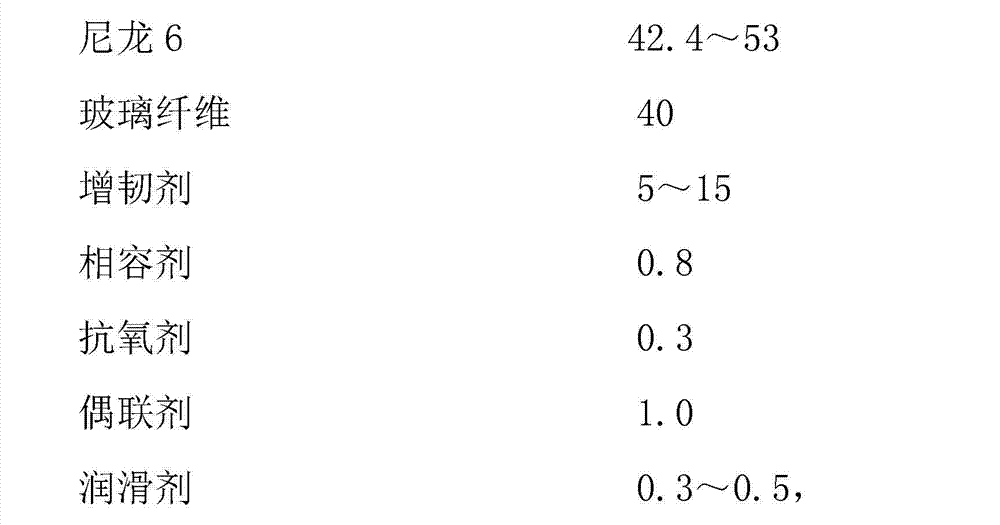

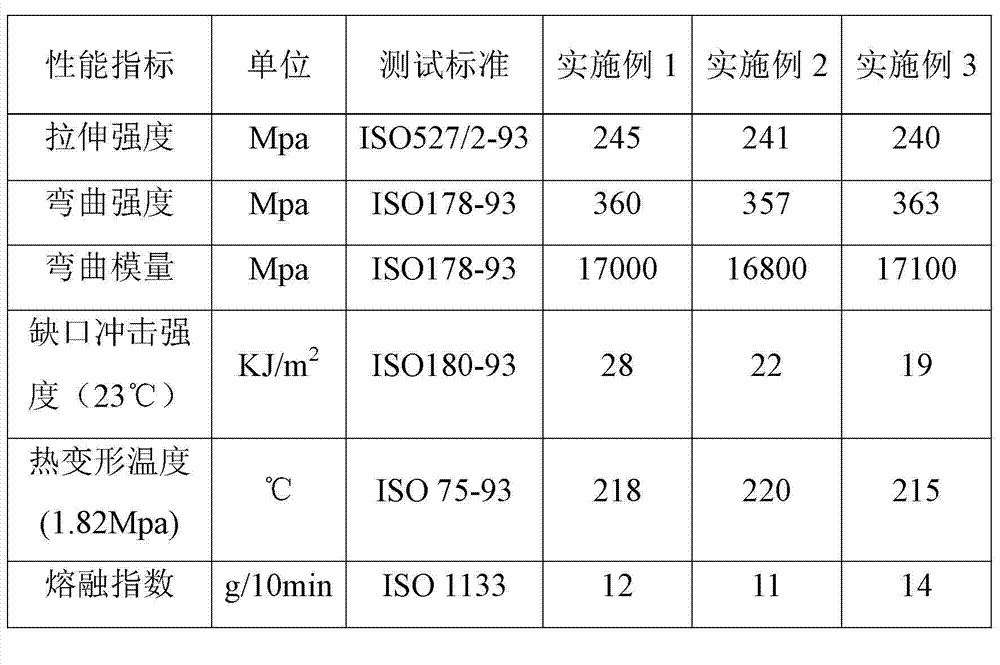

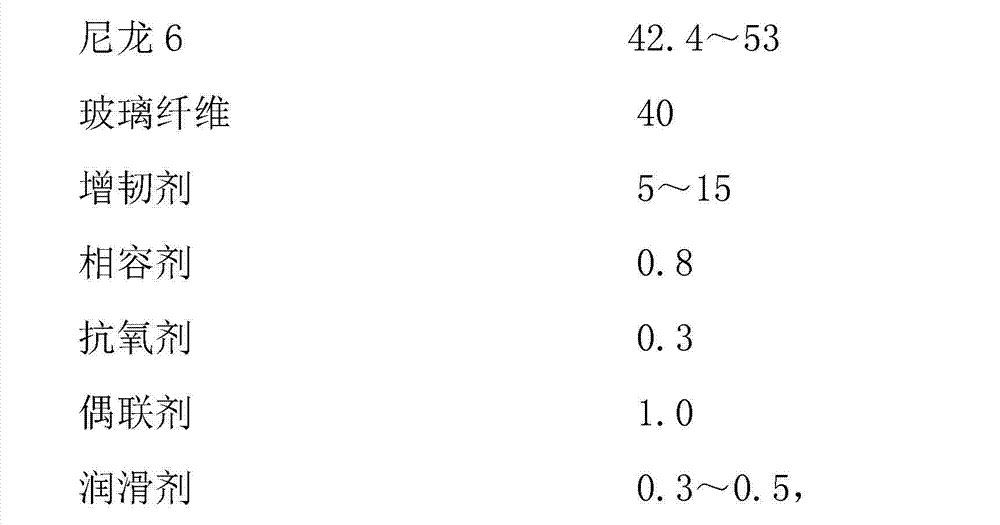

[0020] Formula: 53 parts by weight of nylon 6 (PA6), 5.0 parts by weight of toughening agent (EVA), 0.8 parts by weight of compatibilizer (maleic anhydride graft copolymer), 0.3 parts by weight of antioxidant (1010:168=1:1) Parts by weight, coupling agent (γ-(methacryloxy) chloropropyltrimethoxysilane) 1.0 parts by weight, lubricant (TAF) 0.3 parts by weight, glass fiber 40 parts by weight.

[0021] Preparation:

[0022] (1) Mixing of main and auxiliary materials

[0023] Mix and stir the main ingredient PA6 with toughening agent, compatibilizer, antioxidant, coupling agent and lubricant to fully disperse the components;

[0024] (2), melt extrusion

[0025] Put the mixed material into the twin-screw extruder, and at the same time of melt extrusion, introduce glass fiber to melt and extrude, and the melt extrusion temperature is in the range of 240-260°C;

[0026] (3) Granulation and post-cooling, air-drying, pelletizing, sieving, magnetic passing, packaging to obtain the f...

Embodiment 2

[0028] Formula: 47.5 parts by weight of nylon 6 (PA6), 10 parts by weight of toughening agent (EVA), 0.8 parts by weight of compatibilizer (maleic anhydride graft copolymer), 0.3 parts by weight of antioxidant (1010:168=1:1) Parts by weight, coupling agent (γ-(methacryloyloxy) chloropropyltrimethoxysilane) 1.0 parts by weight, lubricant (TAF) 0.4 parts by weight, glass fiber 40 parts by weight.

[0029] The preparation method is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0031] Formula: 42.4 parts by weight of nylon 6 (PA6), 15 parts by weight of toughening agent (EVA), 0.8 parts by weight of compatibilizer (maleic anhydride graft copolymer), 0.3 parts by weight of antioxidant (1010:168=1:1) Parts by weight, coupling agent (γ-(methacryloxy) chloropropyltrimethoxysilane) 1.0 parts by weight, lubricant (TAF) 0.5 parts by weight, glass fiber 40 parts by weight.

[0032] The preparation method is the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com