Wheel set traction automatic leaning type ultraviolet inactivation device

An automatic cleaning and wheel set technology, applied in the field of inactivation, can solve the problems of complex hydraulic transmission structure, high requirements for supporting facilities, and large friction resistance of screw pair transmission, so as to improve reliability and maintainability, and reduce maintenance. Workload, effect of automation and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

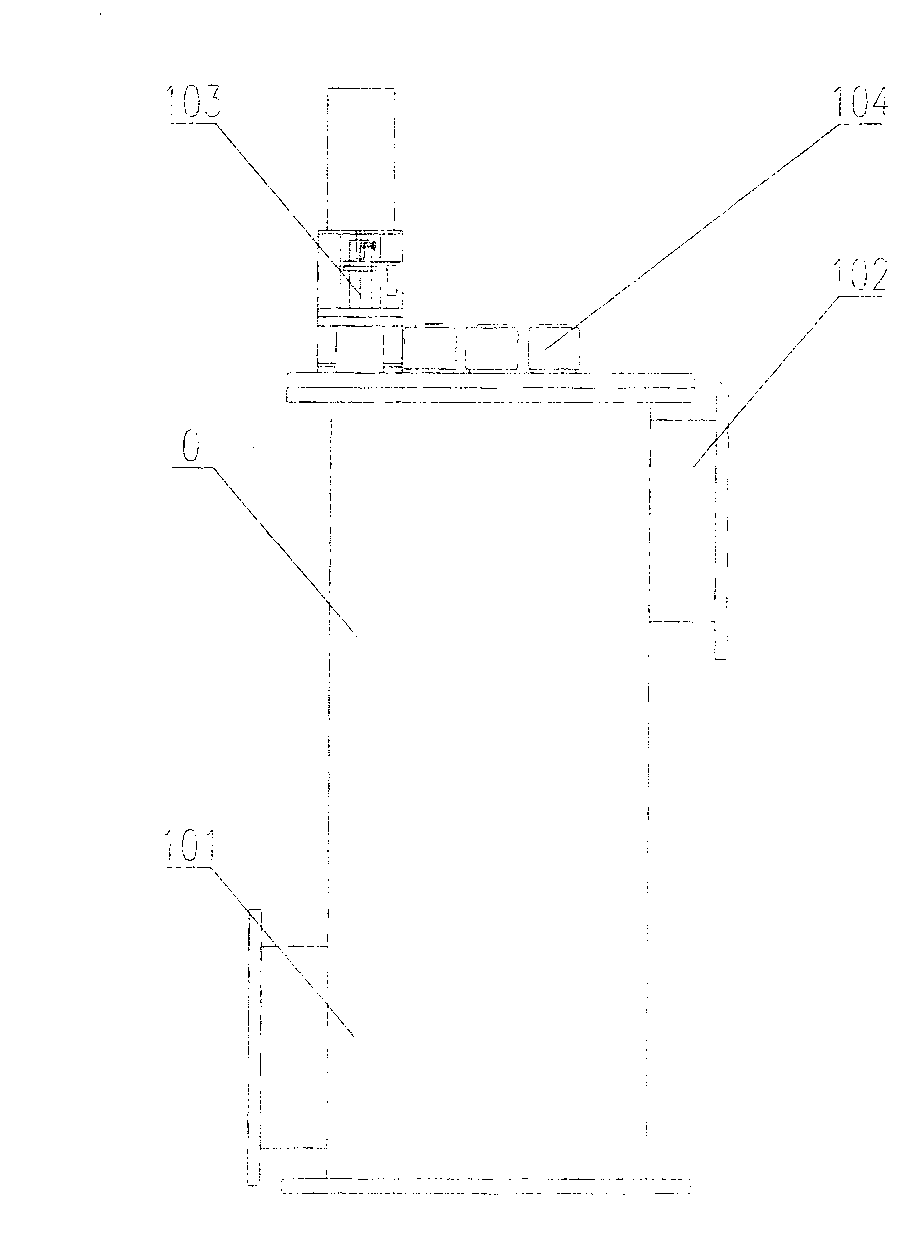

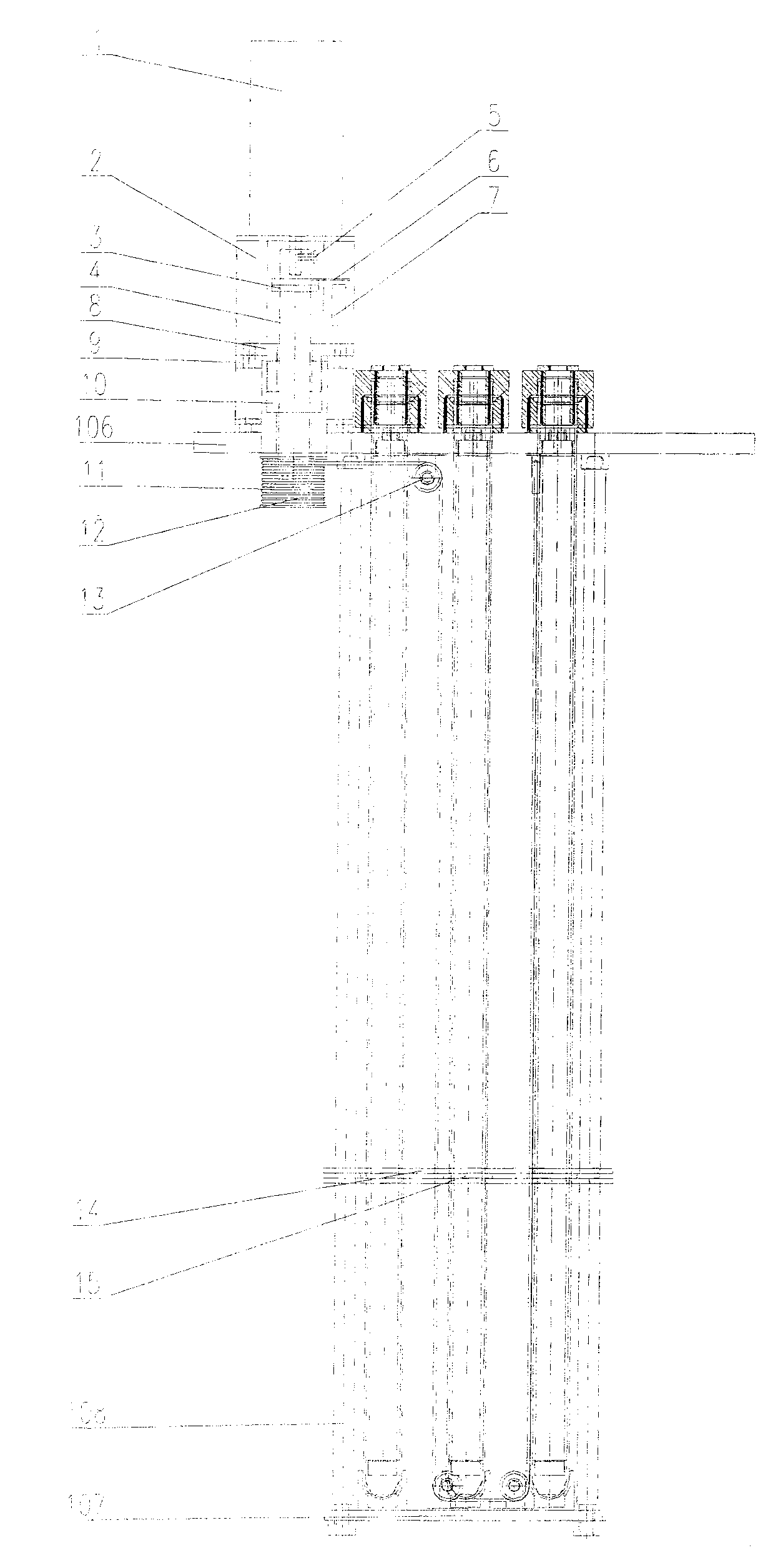

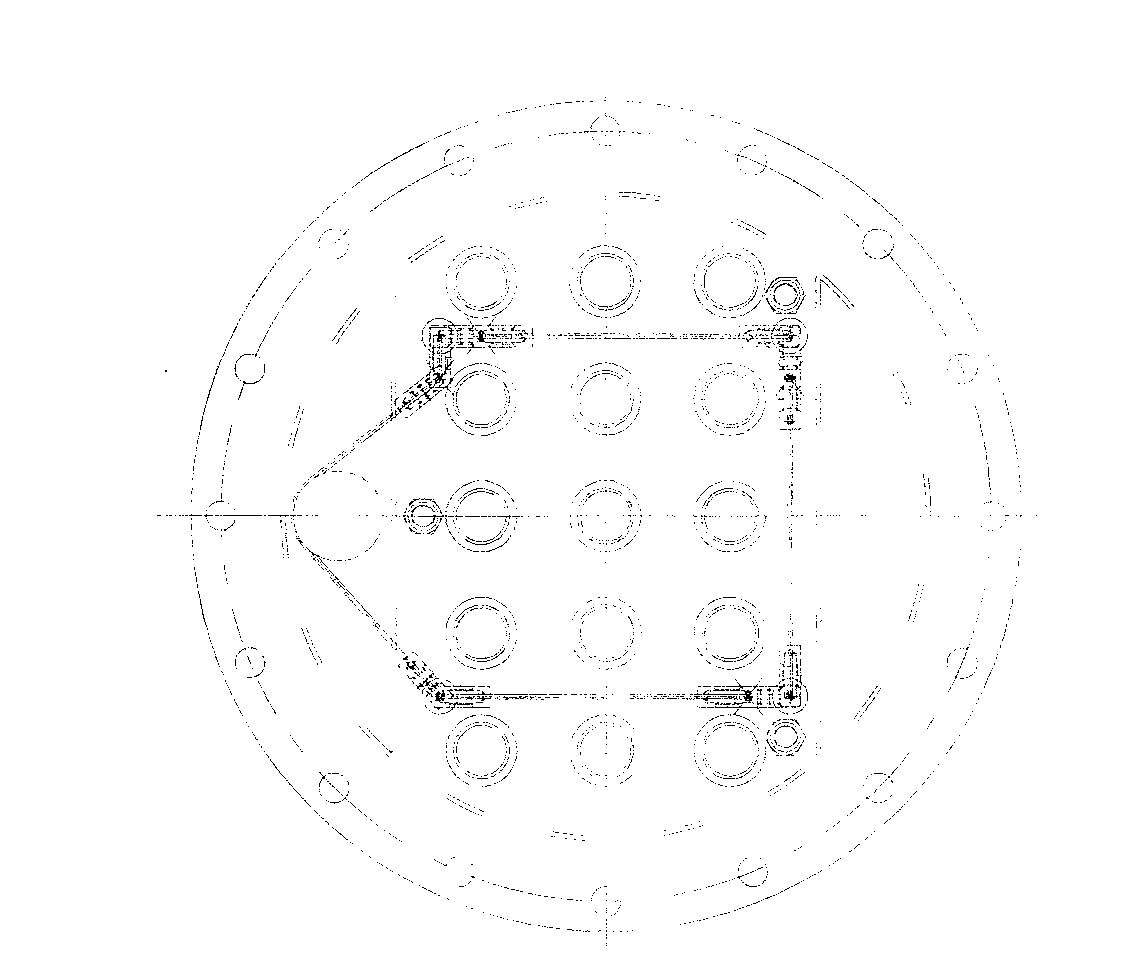

[0010] Such as figure 1 Shown is the structural representation of the ultraviolet deactivation device of the present invention, and the deactivation device shown in the figure is composed of a body (0), a water inlet pipe (101), a water outlet pipe (102), a top automatic cleaning mechanism (103) and an ultraviolet lamp (104 ) form, the automatic cleaning mechanism (103) is as figure 2 As shown, it is installed on the top plate (106), the automatic cleaning mechanism (103) is composed of the bottom plate (107) and the connecting rod (108) in an integral frame structure, and this assembly is fixed with the UV inactivation body (0) by bolts . On the top plate (106), a motor bracket (2) is also installed, and the motor (1) is fixed with the motor bracket (2) by bolts. The motor (1) is a 4-stage geared motor, the output speed is 15r / min, and the reduction ratio 1:100. The output shaft of the motor is connected with the drive shaft (4) through the coupling (3), and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com