Apparatus and method used for determining thermal contact resistance in hot stamping process

A technology of contact thermal resistance and hot stamping, applied in the field of hot stamping of high-strength steel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings.

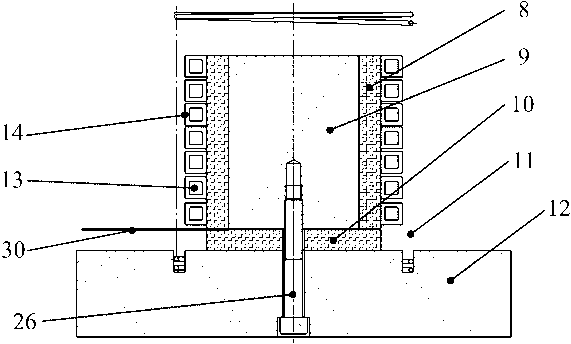

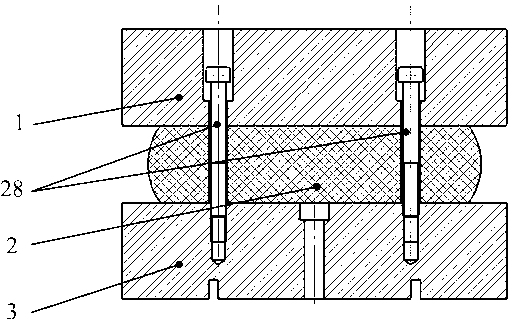

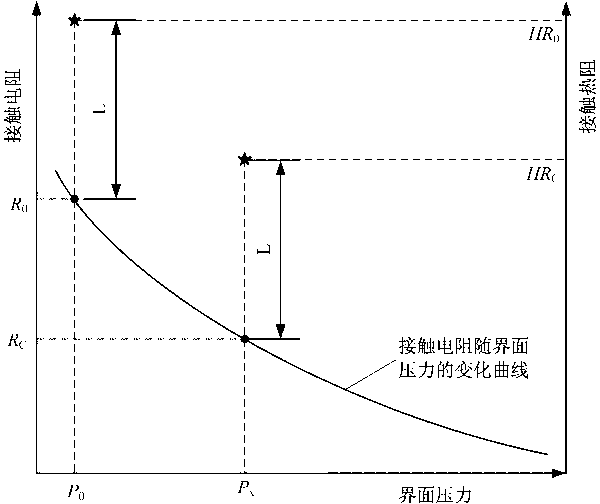

[0073] A device for measuring the contact thermal resistance between a high-temperature steel plate and a mold during hot stamping, including a pressure applying device, a measuring device and a resistance data acquisition module, the measuring device including a sample measuring tool, a standard module tooling and a standard test tool The sample tooling, the sample measuring tooling, the standard module tooling and the standard sample tooling are respectively connected to the resistance data acquisition module through wires:

[0074] The pressurizing device includes a pressurizing device, an upper workbench and a lower workbench, and the pressurizing device is connected with the upper workbench and the lower workbench respectively; the measuring device includes an upper tooling, a lower tooling and a sample fixing tooling, The upper tooling is fixed on the upper workb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Winding thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com