Multi-core optical fiber composite carrier cable production device and production process

A technology of multi-core optical fiber and production process, which is applied in the field of production equipment of multi-core optical fiber composite catenary, can solve the problems of increased production cost, unreasonable production process, consuming manpower and material resources, etc., so as to improve the strength and improve the quality of operation and maintenance , the effect of preventing the damage of optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

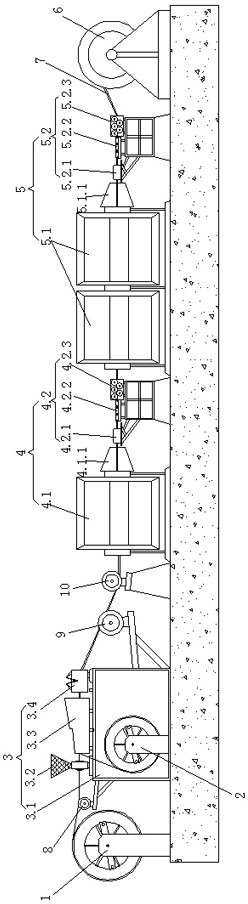

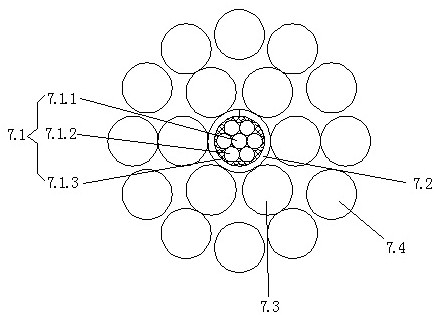

[0030] See figure 1 and figure 2 The present invention relates to an apparatus for the production of composite multi-core optical fiber catenary, comprising a fiber line planes, stainless steel frame 2 defense, cover means 3, a wind mechanism 4, 5 and the second wire payout mechanism frame 6, the covering means 3, a means 4 strands, the secondary strands 5 and pay-off means 6 sequentially disposed from front to back, said cover means 3 comprises a base 3.1, the base 3.1 front to back order, an insulating coating components 3.2, 3.3 and cladding member welded assembly line 3.4, the primary strands means 4 are provided in this order from front to back a primary strands means 4.1 and 4.2 straightening means, said means primary strand end is provided with a multi-core 4.1 pre-deformation mold 4.1.1, 4.1.1 of the center of the mold a pre-deformed for a multi-core optical fiber to pass through, a plurality of circumferential core mold 4.1.1 pre-deformation both the cloth a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com