Preparation method of TiO2-nanotube-array-supported ruthenium-containing coating catalyst

A nanotube array, coating catalyst technology, applied in coatings, surface reaction electrolytic coatings, electrolytic coatings, etc., can solve the problems of small chlorine-oxygen potential difference, poor stability, etc., to enhance the force, prolong life, inhibit the The effect of oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

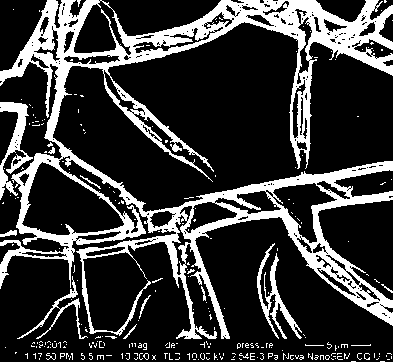

[0028] (1), TiO 2 Nanotube array preparation

[0029] First, the Ti wafer is mechanically polished to remove surface oxides, and then sonicated in acetone and ethanol for 15 minutes, and then treated with a chemical polishing solution for 30 seconds. The polishing solution is a mixed aqueous solution of concentrated nitric acid and hydrofluoric acid, and the volume ratio is HF : HNO 3 : H 2 O =1:4:5, finally rinse with ultrapure water for use; adopt a two-electrode system, with Ni plate as the counter electrode, Ti plate as the working electrode, and 0.5% hydrofluoric acid aqueous solution as the electrolyte solution. At room temperature, apply a voltage of 20 V between the working electrode and the counter electrode for 40 minutes, rinse with ultrapure water, and dry to obtain TiO 2 Nanotube array

[0030] (2) Preparation of coating solution

[0031] The coating solution was prepared with a 1:1 mixture of isopropanol and ethanol as a solvent, in which the molar concentration of rut...

Embodiment 2

[0038] Step (1) is the same as step (1) in Example 1

[0039] (2) Preparation of coating solution

[0040] The coating solution was prepared with a 1:1 mixture of isopropanol and ethanol as the solvent, in which the molar concentration of ruthenium trichloride was 0.20 mol / L; the molar concentration of n-tetrabutyl titanate was 0.22 mol / L; tetrachloride The molar concentration of tin is 0.20 mol / L; the molar concentration of antimony trichloride is 0.04 mol / L;

[0041] (3) Preparation of catalytic electrode containing ruthenium coating

[0042] TiO per square centimeter 2 Nanotube array 0.05 ml, take the coating solution prepared in step (2), and coat the TiO prepared in step (1) in 20 times 2 On the nanotube array, from the 1st to the 19th, after each coating, they were dried under an infrared lamp, and then transferred to a muffle furnace for thermal oxidation at 500°C for 10 minutes. Keep the temperature at ℃ for 1 hour, and then cool to room temperature with the furnace temperatu...

Embodiment 3

[0047] Step (1) is the same as step (1) in Example 1

[0048] (2) Preparation of coating solution

[0049] The coating solution was prepared with a 1:1 mixture of isopropanol and ethanol as the solvent, in which the molar concentration of ruthenium trichloride was 0.10 mol / L, the molar concentration of tin tetrachloride was 0.20 mol / L, trichloride The molar concentration of antimony is 0.03 mol / L;

[0050] (3) Preparation of catalytic electrode containing ruthenium coating

[0051] TiO per square centimeter 2 Nanotube array 0.2ml, take the coating solution prepared in step (2), and coat the TiO prepared in step (1) in 10 times 2 On the nanotube array, from the first to the ninth time, after each coating, they are dried under an infrared lamp, and then transferred to a muffle furnace for thermal oxidation at 400°C for 15 minutes. Keep the temperature at ℃ for 2 hours, and cool to room temperature with the furnace temperature to prepare the ruthenium-containing coating catalyst.

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com