Method for removing trace hydrocarbon from aromatic hydrocarbon by utilizing AlPO4-5 type Al-P molecular sieve

A phospho-aluminum molecular sieve, aromatic hydrocarbon technology, applied in molecular sieve catalyst, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve the problems of weak surface acidity, hindering application, etc., achieves small environmental impact, good activity stability, process Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

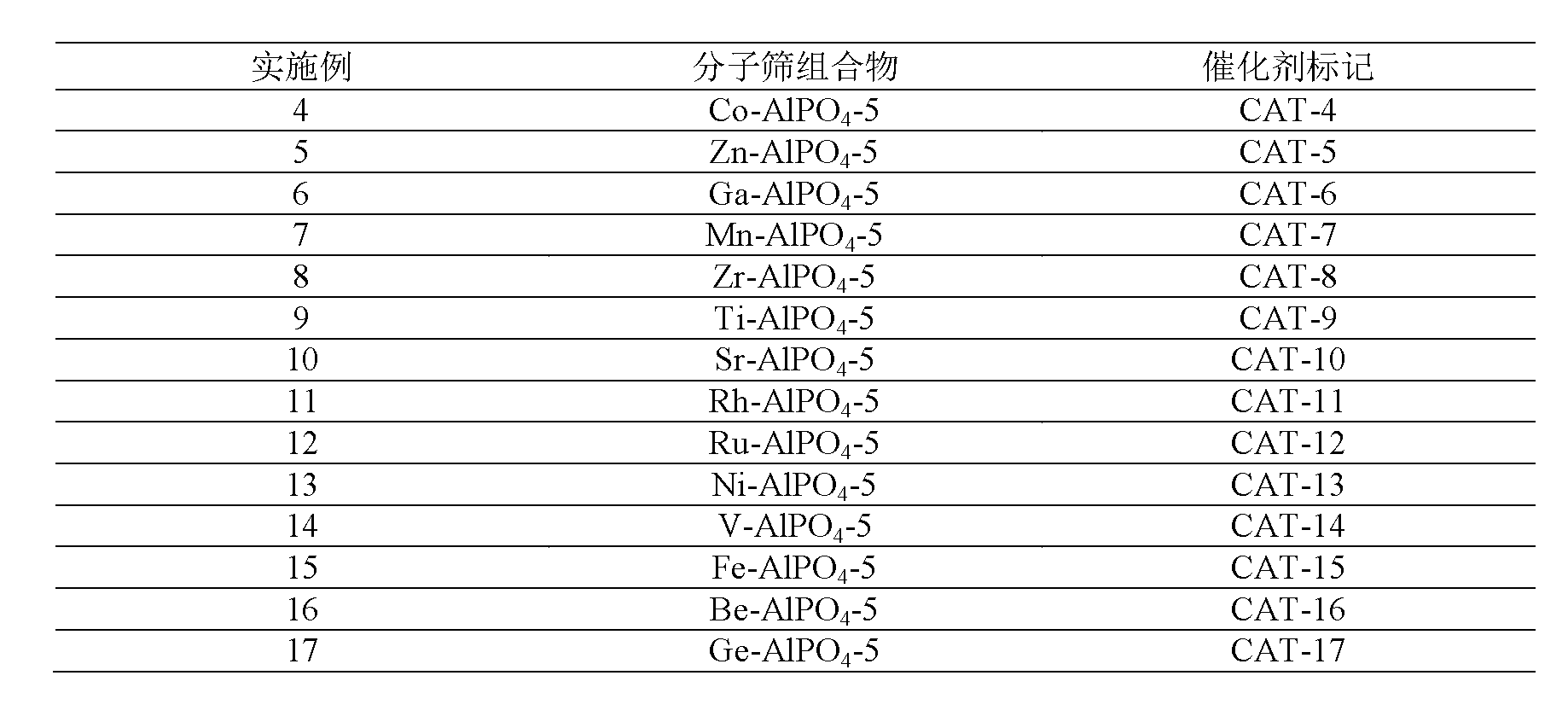

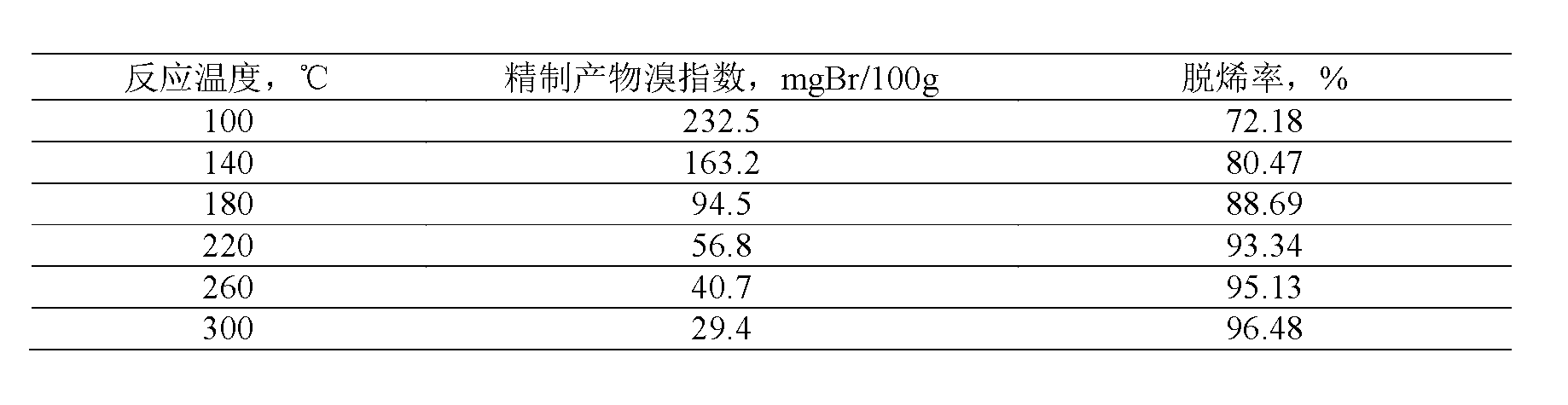

Examples

Embodiment 1

[0028] Synthesis of B-AlPO 4 -5 molecular sieve catalyst, denoted as CAT-1.

[0029] According to Al 2 o 3 :P 2 o 5 :B 2 o 3 :OXAA:H 2 O: ETHA: TYEA raw material molar ratio 1: 0.432: 0.191: 0.304: 25.368: 2.352: 0.756, weigh 40 grams of monohydrate alumina (Shandong Aluminum Group Corporation), and the corresponding amount of phosphoric acid (H 3 PO 4 , 85Wt%), boric acid, oxalic acid (OXAA), deionized water, ethanol (ETHA) and triethylamine (TYEA), prepare a mixed solution, stir and mix at room temperature (25°C) for 3 hours and then place it in a crystallization reactor crystallized at 150°C for 3 days; then filtered, washed with water, dried, and calcined at 550°C for 5 hours to obtain anhydrous chemical composition (B 0.118 al 0.616 P 0.266 )O 2 The boron isomorphously substituted borophosphorus aluminum molecular sieve, denoted as CAT-1.

Embodiment 2

[0031] Synthesis of Mg-AlPO 4-5 molecular sieve catalyst, denoted as CAT-2.

[0032] According to Al 2 o 3 :P 2 o 5 :MgO:OXAA:H 2 O: ETHA: TPPA raw material molar ratio 1: 0.812: 0.423: 0.061: 33.516: 4.362: 1.348, weigh 40 grams of monohydrate alumina, and the corresponding amount of phosphoric acid (H 3 PO 4 , 85Wt%), magnesium acetate, oxalic acid (OXAA), distilled water, ethanol (ETHA), tri-n-propylamine (TPPA), prepared a mixed solution, stirred and mixed at room temperature for 8 hours, then placed in a crystallization reactor, crystallized at 180 ° C 1 day; then filtered, washed with water, dried, and roasted at 600°C for 3 hours to obtain anhydrous chemical composition (Mg 0.105 Al 0.494 P 0.401 )O 2 Magnesium phosphorus aluminum molecular sieve.

Embodiment 3

[0034] Synthesis of Si-Nb-AlPO 4 -5 molecular sieve catalyst, denoted as CAT-3.

[0035] According to Al 2 o 3 :P 2 o 5 : Nb 2 o 5 : SiO 2 :H 2 O: TEAN raw material molar ratio 1: 1.435: 0.316: 0.465: 48.625: 2.863, weigh 40 grams of monohydrate alumina, and the corresponding amount of phosphoric acid (H 3 PO 4 , 85Wt%), niobic acid, silica sol, deionized water and triethanolamine (TEAN), prepare a mixed solution, stir and mix at room temperature for 10 hours, then place it in a crystallization reactor, crystallize at 120°C for 5 days; then filter , washed with water, dried, and calcined at 500°C for 5 hours to obtain anhydrous chemical composition (Si 0.078 Nb 0.106 Al 0.335 P 0.481 )O 2 Silicon-niobium-phosphorus-aluminum molecular sieves isomorphously substituted by silicon and niobium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com