Super weather-resisting, wear-resisting and anti-icing wind-powered blade coating and preparation method thereof

A technology for wind turbine blades and anti-icing, applied in the field of coatings, can solve the problems of poor weather resistance, poor wear resistance, unpainted weather resistance and wear resistance research, etc., to achieve outstanding weather resistance, high construction efficiency at room temperature, and excellent The effect of hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a super-weather-resistant, wear-resistant and anti-icing wind power blade coating and its preparation method are specifically described with examples, but not limited to this specific example. The proportioning in the examples is calculated in parts by mass.

[0054]

Embodiment 1

[0056] A: Sanai rich fluorocarbon resin JF-2X 44

[0057] Wuxi Hudai Chemical Polyester Resin 3090 10

[0058] Silane coupling agent KH550 0.5

[0059] Wetting and dispersing additive BYK-161 2

[0060] Organic bentonite 2

[0061] Nano Titanium Dioxide 1

[0062] Nano alumina 6

[0063] Rutile titanium dioxide 12

[0065] matting powder 6

[0066] UV absorber TINUVIN 326 1

[0067] Leveling agent BYK-354 0.1

[0068] Defoamer BYK-A530 0.4

[0069] Thinner 5

[0070] B: N75

[0071] Among them, the diluent is composed of propylene glycol methyl ether acetate, butyl acetate and xylene=1:1:1 (mass ratio).

[0072] The preparation method is:

[0073] 1. Component A:

[0074] (1) Add fluorocarbon resin, silane coupling agent and half of the diluent into the dispersion tank, stir for 10-20 minutes, add nano-titanium dioxide and nano-alumina under stirring, then disperse at high speed for 15-20 minutes, ball mill for 24 ~96h, get a slurry with ...

Embodiment 2

[0082] A: Changxing Fluorocarbon Resin 4101 27

[0083] Degussa polyester resin T1136 25

[0084] Silane coupling agent KH560 2

[0085] Wetting and dispersing additive BYK-163 0.5

[0087] Nano Titanium Dioxide 5

[0088] Nano alumina 3

[0089] Rutile titanium dioxide 15

[0090] Quartz powder 7.2

[0091] Matting Powder 3.89

[0092] UV absorber TINUVIN 944 0.1

[0093] Leveling agent BYK-356 0.8

[0094] Defoamer Fomex N 0.01

[0095] Thinner 10

[0096] B: N3390

[0097] Among them, the diluent is composed of propylene glycol methyl ether acetate, butyl acetate and xylene=1:2:1 (mass ratio).

[0098] The preparation method is the same as in Example 1.

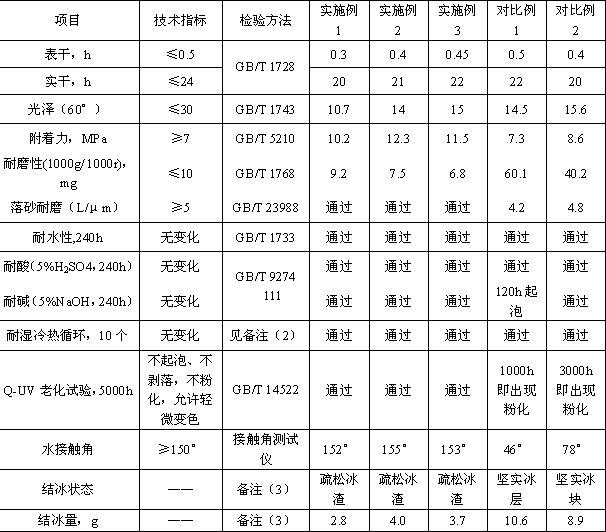

[0099] The performance of the prepared coating meets the technical specifications in Table 1, and the specific indicators are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com