In-situ preparation method of ferroelectric-dielectric composite ceramic material

A multi-phase ceramic, in-situ preparation technology, applied in the field of electronic materials, can solve the problems of coarse particles, low interface bonding strength, thermodynamic instability, etc., and achieve the effects of low production cost, improved microwave performance, and improved density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] A part of 0.0475mol of Ba(CH 3 COO) 2 , 0.0475mol of Sr(CH 3 COO) 2 and 0.01mol of Mg(CH 3 COO) 2 ; One part of 0.04mol Ba(CH 3 COO) 2 , 0.04mol of Sr(CH 3 COO) 2 and 0.04mol of Mg(CH 3 COO) 2 ; One part of 0.025mol of Ba(CH 3 COO) 2 , 0.025mol of Sr(CH 3 COO) 2 and 0.1mol of Mg(CH 3 COO) 2 ; One part of 0.01mol of Ba(CH 3 COO) 2 , 0.01mol of Sr(CH 3 COO) 2 and 0.16mol of Mg(CH 3 COO) 2 , respectively dissolved in 100ml of glacial acetic acid to obtain four solutions containing Ba, Sr and Mg;

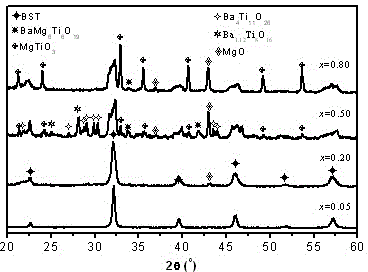

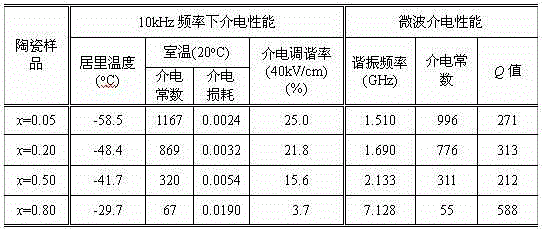

[0020] 0.1molC 16 h 36 o 4 Ti dissolved in 0.2molC 5 h 8 o 2 Obtain Ti-containing solution; Mix the above-mentioned four kinds of solutions containing Ba, Sr and Mg with Ti solution respectively, and stir evenly to obtain (1- x ) Ba 0.5 Sr 0.5 TiO 3 - x Mg 2 TiO 4 ( x =0.05, 0.20, 0.50 and 0.80) precursor solution (raw material ratio shown in Table 1); the precursor solution at 110 o C drying, and then in a muffle furnace at 400o C heat treatme...

example 2

[0030] A part of 0.057mol of Ba(CH 3 COO) 2 , 0.038mol of Sr(CH 3 COO) 2 and 0.01mol of Mg(CH 3 COO) 2 ; One part of 0.048mol of Ba(CH 3 COO) 2 , 0.032mol of Sr(CH 3 COO) 2 and 0.04mol of Mg(CH 3 COO) 2 ; One part of 0.03mol of Ba(CH 3 COO) 2 , 0.02mol of Sr(CH 3 COO) 2 and 0.1mol of Mg(CH 3 COO) 2 ; One part of 0.012mol of Ba(CH 3 COO) 2 , 0.008mol of Sr(CH 3 COO) 2 and 0.16mol of Mg(CH 3 COO) 2 , respectively dissolved in 100ml of glacial acetic acid to obtain four solutions containing Ba, Sr and Mg;

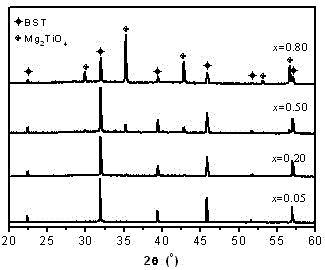

[0031] 0.1molC 16 h 36 o 4 Ti dissolved in 0.2molC 5 h 8 o 2 Obtain Ti-containing solution; Mix the above-mentioned four kinds of solutions containing Ba, Sr and Mg with Ti solution respectively, and stir evenly to obtain (1- x ) Ba 0.6 Sr 0.4 TiO 3 - x Mg 2 TiO 4 ( x =0.05, 0.20, 0.50 and 0.80) precursor solution (raw material ratio shown in Table 3); the precursor solution at 110 o After drying at C temperature, in a muffle furnace at 400 ...

example 3

[0036] A part of 0.0285mol of Ba(CH 3 COO) 2 , 0.0665mol of Sr(CH 3 COO) 2 and 0.01mol of Mg(CH 3 COO) 2 ; One part of 0.024mol of Ba(CH 3 COO) 2 , 0.056mol of Sr(CH 3 COO) 2 and 0.04mol of Mg(CH 3 COO) 2 ; One part of 0.015mol of Ba(CH 3 COO) 2 , 0.035mol of Sr(CH 3 COO) 2 and 0.1mol of Mg(CH 3 COO) 2 ; One part of 0.006mol of Ba(CH 3 COO) 2 , 0.014mol of Sr(CH 3 COO) 2 and 0.16mol of Mg(CH 3 COO) 2 , respectively dissolved in 100ml of glacial acetic acid to obtain four solutions containing Ba, Sr and Mg;

[0037] 0.1molC 16 h 36 o 4 Ti dissolved in 0.2molC 5 h 8 o 2 Obtain Ti-containing solution; Mix the above-mentioned four kinds of solutions containing Ba, Sr and Mg with Ti solution respectively, and stir evenly to obtain (1-x ) Ba 0.3 Sr 0.7 TiO 3 - x Mg 2 TiO 4 ( x =0.05, 0.20, 0.50 and 0.80) precursor solution (raw material ratio shown in Table 4); o After drying at C temperature, in a muffle furnace at 400 o C heat treatment for 2h f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com