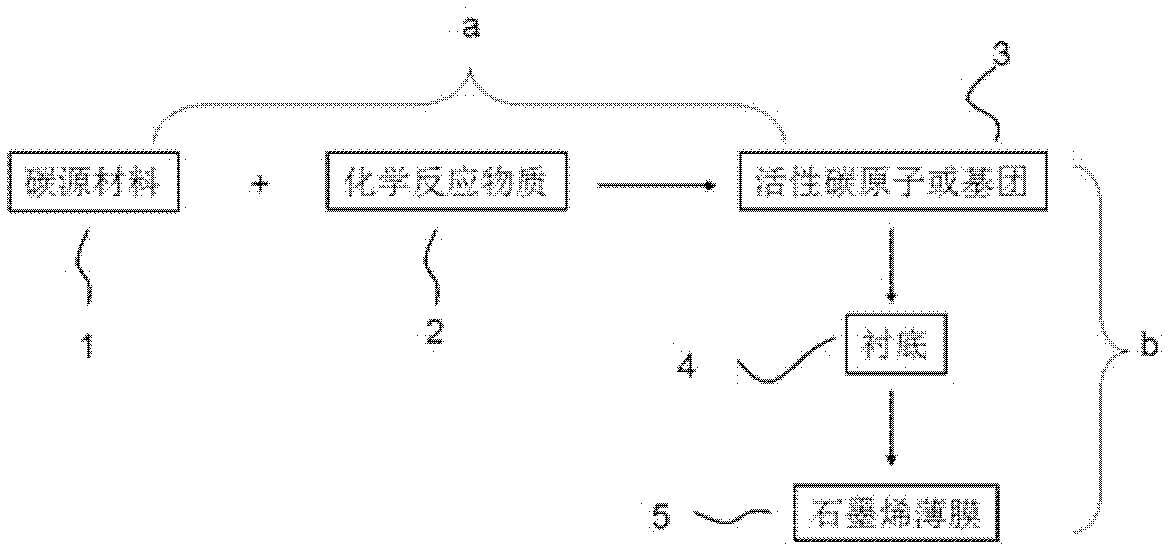

Method for synthesizing graphene film through chemical reaction

A graphene film and chemical reaction technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of poor electronic transport performance of graphene film, and achieve the effect of expansion selectivity, easy control of size and wide reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the ionization of alcohols grows graphene film on Si (100) substrate

[0030] Include the following steps:

[0031] 1) Alcohol is dissociated into carbocations under the catalysis of Lewis acid (Lewis acid), and the reaction process is:

[0032] R-OH+H + →R + -OH 2 →R + +H 2 O, where R stands for C n h 2n+1 (n≥1).

[0033] 2) Put the Si(100) substrate in the above reaction solution, and the generated carbon-containing ions R + Adsorbed on the silicon substrate;

[0034] 3) will be adsorbed with R + The substrate is taken out from the solution, and then this substrate is placed in a quartz tube;

[0035] 4) Pass hydrogen to the quartz tube and heat-treat at 930°C for 10min, and finally drop to 20°C at a cooling rate of 50°C / min to obtain a graphene film with a thickness of about 17nm ( figure 2 ).

[0036] Effect: The chemical reaction that produces active carbon atoms or carbon-containing active groups includes but not limited to heterocleava...

Embodiment 2

[0038] Embodiment 2: Taking non-polar carbon-containing compound as raw material method to synthesize graphene film

[0039] Include the following steps:

[0040] 1) Use superacids to extract negative hydrogen ions from non-polar compounds such as alkanes to generate carbocations. The typical process of this type of reaction is:

[0041] (CH 3 ) 3 C-H+SbF 5 ·FSPO 3 H→(CH 3 ) 3 C + +SbF 5 ·FSPO 3 - +H 2

[0042] 2)(CH 3 ) 3 C-H and SbF 5 ·FSPO 3 H undergoes a chemical reaction to form (CH 3 ) 3 C + After carbocations, guide the reaction product onto the Ni polycrystalline substrate;

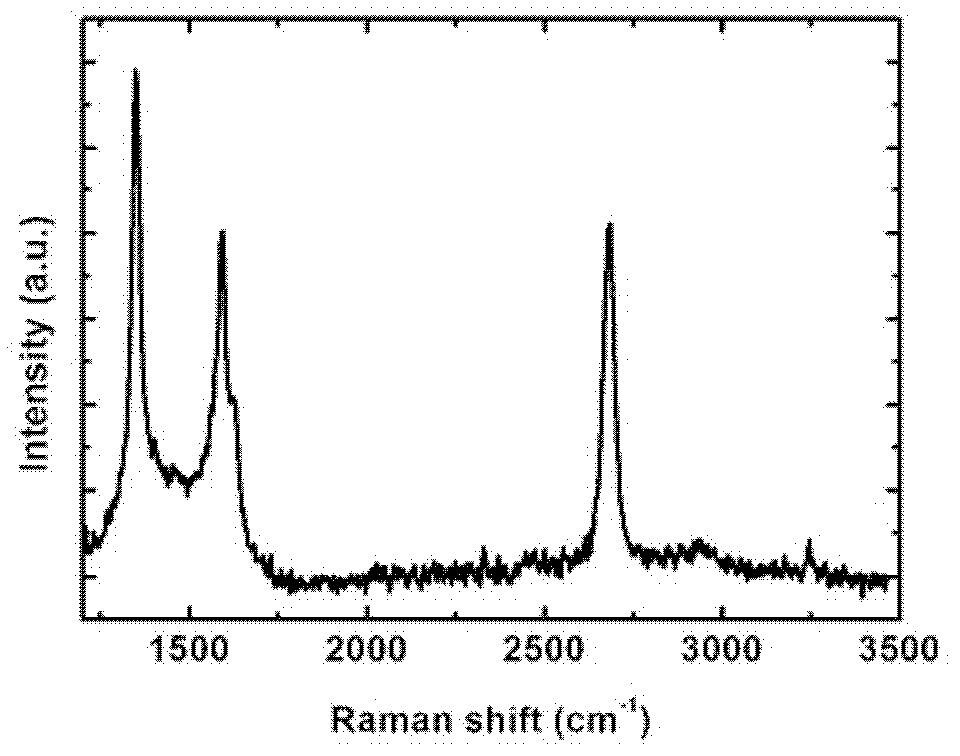

[0043] 3) Then in H 2 In the atmosphere of / Ar, heat treatment at 1000°C for 10 minutes, and finally reduce the temperature to 25°C by 40°C / min, so that graphene with a thickness of 0.335nm was obtained on the Ni substrate; image 3 is the Raman spectrum of the synthesized graphene.

[0044] Effect: The chemical reactions that produce active carbon atoms or carbon-containing ...

Embodiment 3

[0046] Embodiment 3: the addition reaction synthesis graphene film of unsaturated bond

[0047] A typical reaction process is: R-C=R'+H + → R-C-R'H (R is an alkyl group, R' is O, C, N, S) includes the following steps:

[0048] 1) After reacting alkenes such as butene with acids such as HCl, CH 3 -CH 2 -CH=CH 2 +H + →CH 3 -CH 2 -CH 2 -CH 3 , transfer the reaction product to the polymer polyethylene terephthalate (PET) substrate;

[0049] 2) Then electron beams are used to process the reaction product on the PET. During the treatment, the temperature of the PET substrate is kept at 100°C, and the processing time is 3 hours; finally, the temperature is lowered to 25°C to obtain graphene with a thickness of 50nm film( Figure 4 ).

[0050] Effect: The chemical reactions that produce active carbon atoms or carbon-containing active groups include but are not limited to heterocleavage of halogenated hydrocarbons. Alcohols, ethers, and acyl halides can also be dissociated i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com