Load-type phosphotungstic acid catalyst and preparation method thereof as well as n-butyl acrylate preparation method

A technology of phosphotungstic acid and catalyst, which is applied in the field of preparation of n-butyl acrylate, can solve the problems of complex post-treatment process, equipment corrosion, and many side reactions, and achieve less side reactions, good catalytic performance, and simple post-treatment process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

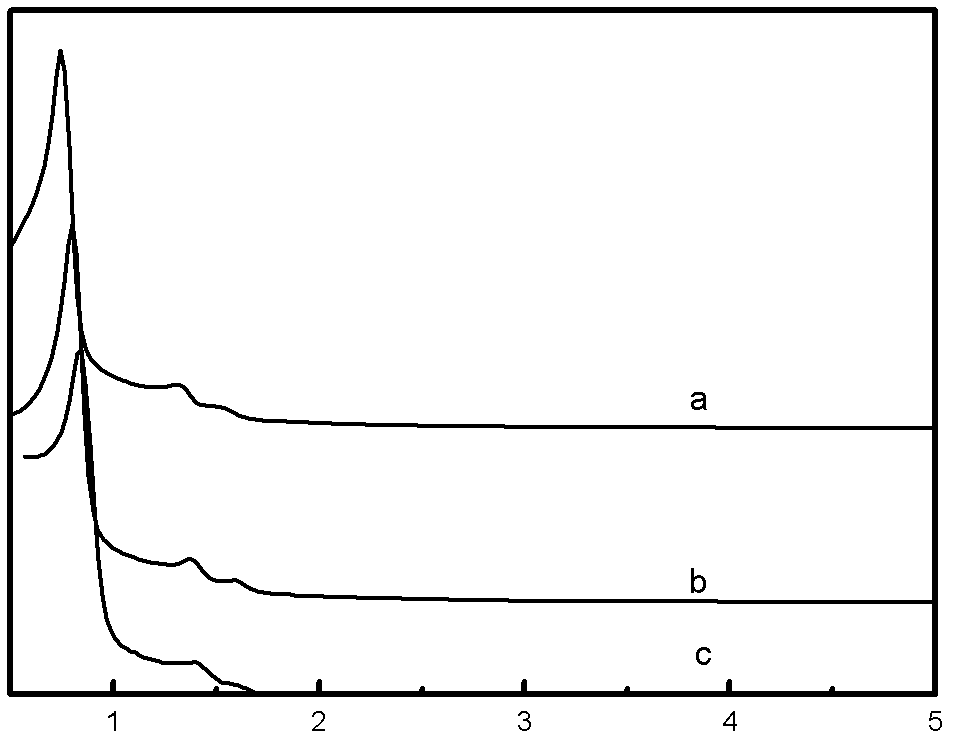

Image

Examples

Embodiment approach

[0024] According to one embodiment of the present invention, the preparation method of the supported phosphotungstic acid catalyst comprises: stirring a hollow mesoporous silica carrier, n-butanol and phosphotungstic acid at a temperature of 100-150°C for 0.5-72 hours After suction filtration, according to molar ratio, hollow spherical mesoporous silica carrier: n-butanol: phosphotungstic acid = 1: 10-50: 0.005-0.1, preferably hollow spherical mesoporous silica carrier: n-butanol: Phosphotungstic acid = 1: 10-20: 0.01-0.06, more preferably hollow spherical mesoporous silica carrier: n-butanol: phosphotungstic acid = 1: 10.51: 0.02, and then dry the solid with nitrogen to obtain a supported Hollow spheres of mesoporous silica of phosphotungstic acid.

[0025] According to the present invention, the size of the hollow spherical mesoporous silica can be changed in a wide range, preferably, the average particle diameter of the hollow spherical mesoporous silica carrier can be 3-20...

Embodiment 1

[0044] Preparation of hollow sphere mesoporous silica support:

[0045] Add 1.0 gram of three-stage copolymer polyethylene glycol-polyglycerol-polyethylene glycol (Aldrich Company, P123) and 1.69 gram of ethanol into the buffer solution (pH=4.4) of acetic acid and sodium acetate of 28ml, in Stir at 15°C until polyethylene glycol-polyglycerol-polyethylene glycol is completely dissolved, then add 6g of trimethylpentane to the above solution, stir at 15°C for 8 hours, then add 2.13g of tetramethoxy Add base silane to the above solution, stir at 15°C for 20 hours, transfer the solution to a polytetrafluoroethylene-lined reaction kettle, and crystallize in an oven at 120°C for 30 hours, then filter, wash with distilled water, and dry to obtain a hollow Spherical mesoporous silica raw powder.

[0046] The hollow spherical mesoporous silica raw powder was calcined in a muffler furnace at 550° C. for 24 hours to obtain hollow spherical mesoporous silica (named MS-1).

[0047] Prepar...

experiment Embodiment 1

[0072] This experimental example is used to illustrate the catalytic activity of the supported phosphotungstic acid catalyst according to the present invention.

[0073] The supported phosphotungstic acid catalyst (MS-HPA) in Example 1 was vacuum-dried at 150°C for 6 hours, and after cooling to room temperature, weighed 0.4 grams, then weighed 8.9 grams of n-butanol and 7.2 grams of acrylic acid, and Put them into a 100ml three-neck flask in turn, stir for 4 hours under heating at 130°C, cool to room temperature, centrifuge, recover the solid catalyst therein, and analyze the composition of the reaction product liquid by gas chromatography. The result is: the conversion of acrylic acid is 90%, and the selectivity to n-butyl acrylate was 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com