Double-layer electrospinning bionic periosteum and method for preparing same

A bionic bone and electrospinning technology, applied in textiles and papermaking, prosthesis, medical science, etc., to achieve the effect of enhancing the adhesion of MSCs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] For the preparation of rFN / CDH fusion protein, please refer to the Chinese invention patent application number 200910103100.6, entitled "Fibronectin-cadherin-11 fusion protein, preparation method and application". The amino acid sequence of the FN / CDH fusion protein is shown in SEQ ID NO:1.

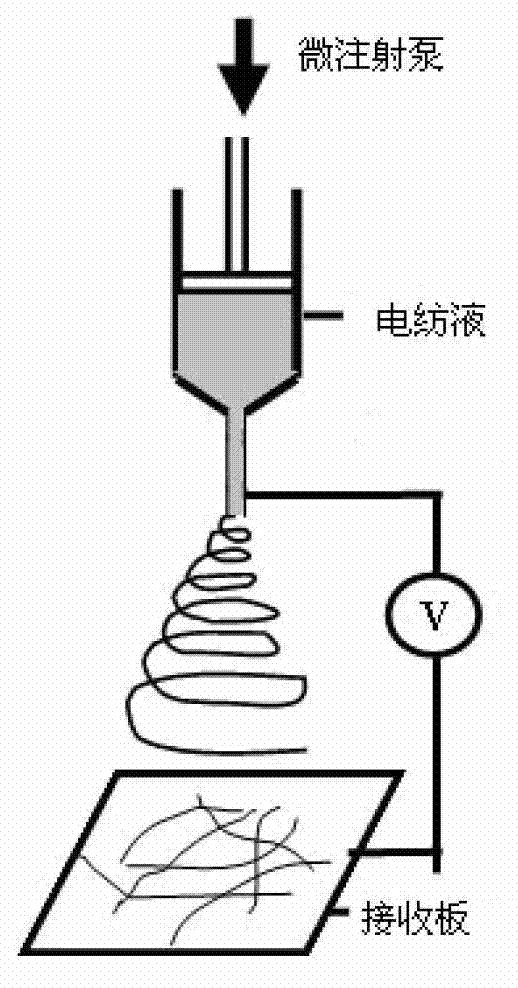

[0031] For electrospinning technology, please refer to Xu Songxiu's master's degree thesis "Research on Electrospinning Nanofibers"

Embodiment 1

[0033] Step 1: 0.8g of chitosan (molecular weight is 240000) is dissolved in 40ml concentration (by volume percentage) and is 25% glacial acetic acid aqueous solution, is made into the A chitosan solution that concentration is 2% (g / ml); The chitosan that 1.2g molecular weight is 88000 is dissolved in 40ml concentration (by volume percentage) is 50% glacial acetic acid aqueous solution, is made into the B chitosan solution that concentration is 3% (g / ml), microheating magnetic stirring 2 Obtained transparent light yellow chitosan glacial acetic acid solution in hours.

[0034] Step 2: Dissolve 10 mg of rFN / CDH fusion protein in 1 ml of deionized water, stir at room temperature until completely dissolved, and obtain a rFN / CDH protein solution with a concentration of 10 mg / ml.

[0035] Step 3: Prepare inner and outer membrane electrospinning liquid: mix B chitosan solution and rFN / CDH protein solution at a volume ratio of 5:1 to obtain a mixed solution of rFN / CDH protein and chi...

Embodiment 2

[0039] Step 1: 1.2g chitosan (molecular weight is 260000) is dissolved in 40ml concentration and is 25% glacial acetic acid aqueous solution, is made into the A chitosan solution that concentration is 2% (g / ml); 1.2g chitosan ( Molecular weight is 102000) be dissolved in 40ml concentration and be 50% glacial acetic acid aqueous solution, be made into the B chitosan solution that concentration is 3% (g / ml), microthermal magnetic stirring obtains transparent pale yellow chitosan glacial acetic acid solution for 2 hours.

[0040] Step 2: Dissolve 5 mg of rFN / CDH fusion protein in 1 ml of deionized water, stir at room temperature until completely dissolved, and obtain a rFN / CDH protein solution with a concentration of 5 mg / ml.

[0041] Step 3: Prepare inner and outer membrane electrospinning liquid: mix B chitosan solution and rFN / CDH protein solution at a volume ratio of 5:1 to obtain a mixed solution of rFN / CDH protein and chitosan, stir at room temperature to obtain inner membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com