Light emitting diode capable of emitting white light

A light-emitting diode, white light technology, applied in the field of fluorescence conversion, can solve the problems of high cost, poor performance, low luminous efficiency, etc., and achieve the effects of low cost, low phase forming temperature, and no pollution in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

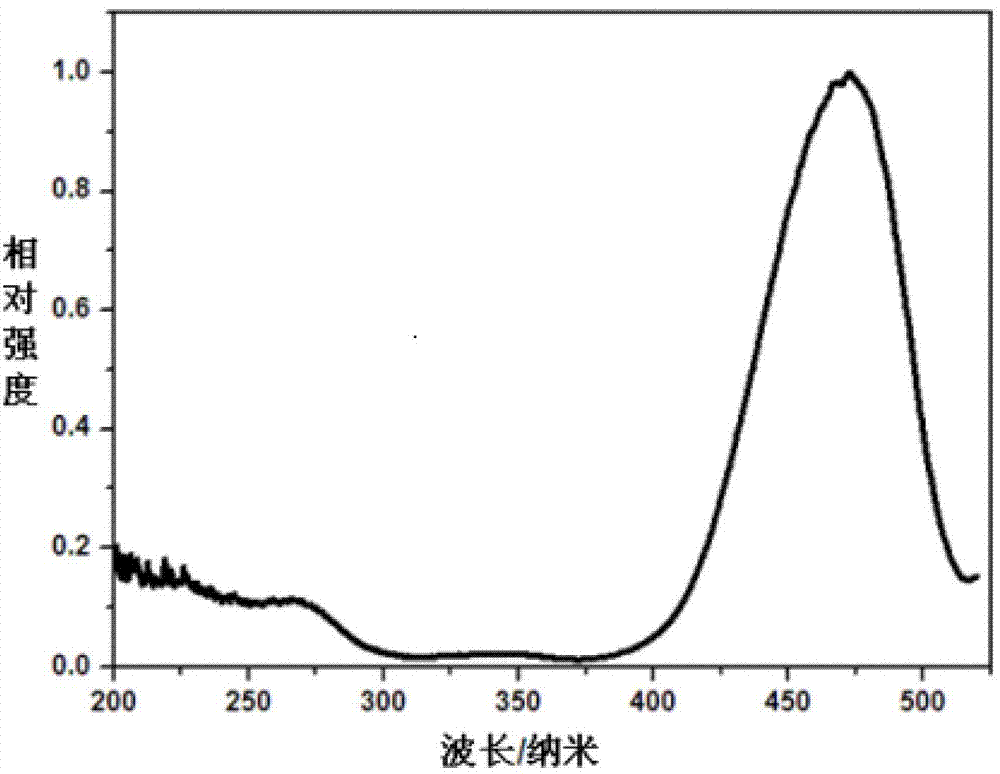

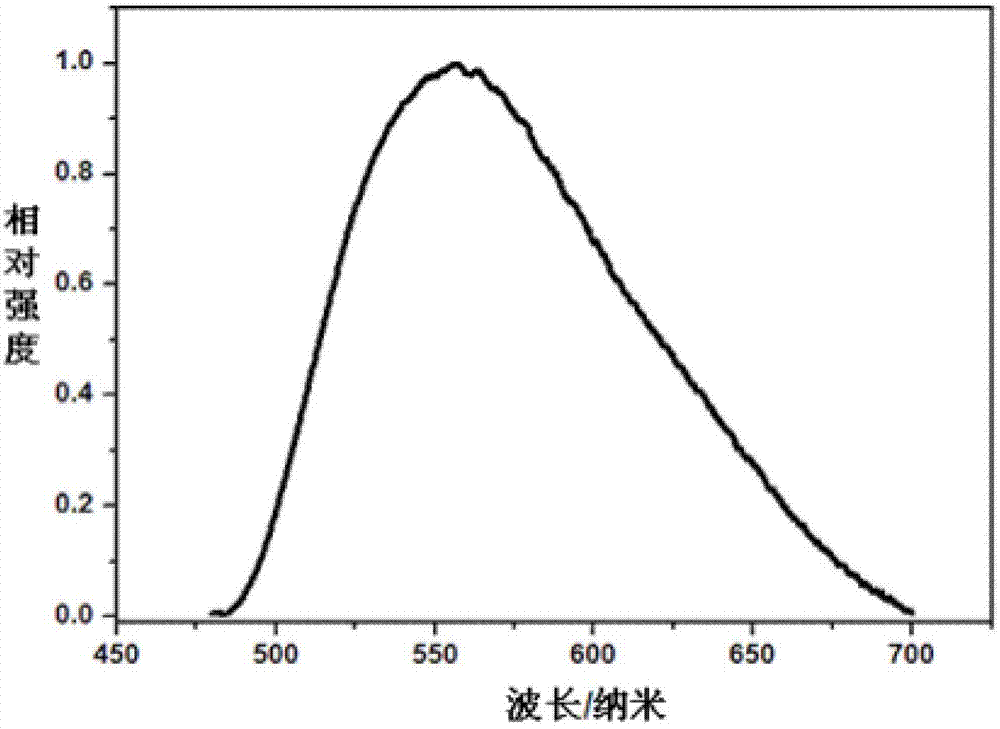

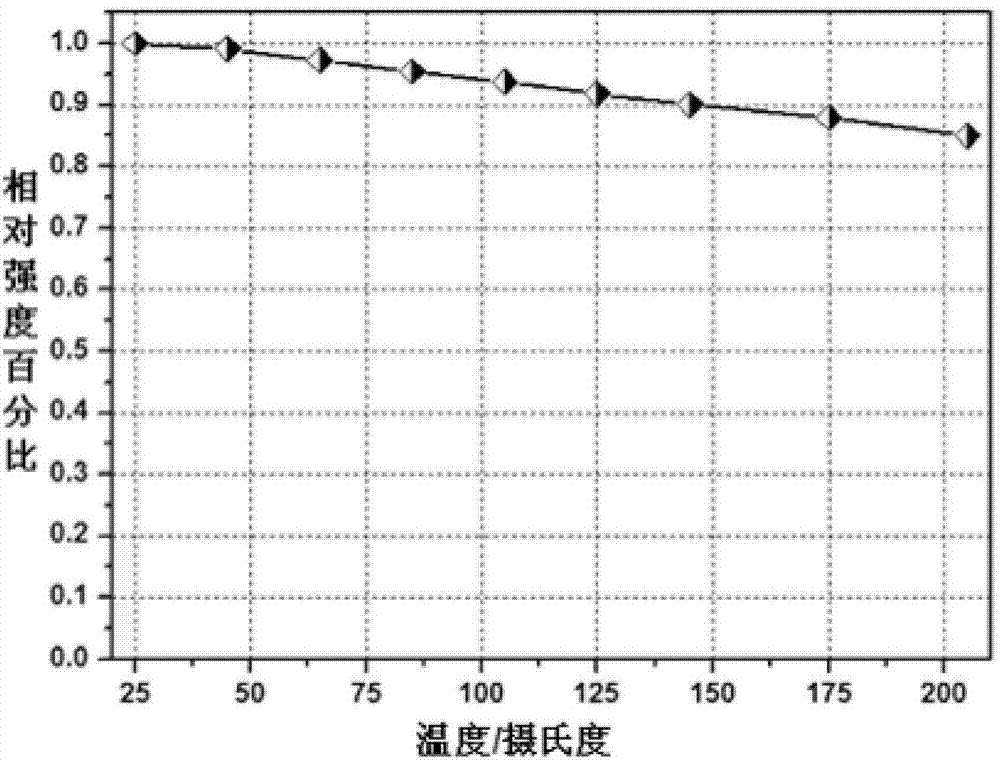

[0030] with the chemical formula as Ca 0.88 Mg 0.1 O:Ce 3+0.01 Li + 0.01 A light-emitting diode emitting white light is prepared from the yellow phosphor powder, wherein, M is Mg, R is Li, a=0.1, x=y=0.01.

[0031] Using high-temperature solid-phase method, according to the chemical formula Ca 0.88 Mg 0.1 O:Ce 3+ 0.01 Li + 0.01 The stoichiometric ratio of each element weighs 4.928g CaO, 0.4gMgO, 0.173g CeO 2 , 0.088g Li 2 CO 3 , fully ground and mixed, placed in a high-purity corundum crucible, in nitrogen-hydrogen mixed gas (N 2 / H 2 ) in a reducing atmosphere, put it into a high-temperature tube furnace, bake at 1300°C for 4 hours, cool, grind, wash, and dry to get the chemical formula Ca 0.88 Mg 0.1 O:Ce 3+ 0.01 Li + 0.01 The yellow light phosphor powder is mixed with epoxy resin at a weight ratio of 10%, coated on the blue light InGaN chip, and after potting and curing, a light emitting diode emitting white light is obtained.

[0032] When the forward d...

Embodiment 2

[0034] with the chemical formula as Ca 0.88 Sr 0.1 O:Ce 3+ 0.01 Li + 0.01 A light-emitting diode emitting white light is prepared from the yellow phosphor powder, wherein, M is Sr, R is Li, a=0.1, x=y=0.01.

[0035] Using high-temperature solid-phase method, according to the chemical formula Ca 0.88 Sr 0.1 O:Ce 3+ 0.01 Li + 0.01 The stoichiometric ratio of each element weighs 4.928g CaO, 1.036g SrO, 0.173g CeO 2 , 0.088g Li 2 CO 3 , fully ground and mixed, placed in a platinum crucible, placed in a muffle furnace under a carbon monoxide (CO) reducing atmosphere, roasted at 1200 ° C for 5 hours, cooled, ground, washed, and dried to obtain the chemical formula Ca 0.88 Sr 0.1 O:Ce 3+ 0.01 Li + 0.01 The yellow light phosphor powder is mixed with the organic silicon material at a weight ratio of 20%, coated on the blue light InGaN chip, and the white light emitting diode is obtained after potting and curing.

[0036] After testing, the color rendering index of th...

Embodiment 3

[0038] with the chemical formula as Ca 0.88 Ba 0.1 O:Ce 3+ 0.01 Li + 0.01 A light-emitting diode emitting white light is prepared from the yellow phosphor powder, wherein, M is Ba, R is Li, a=0.1, x=y=0.01.

[0039] Using high-temperature solid-phase method, according to the chemical formula Ca 0.88 Ba 0.1 O:Ce 3+ 0.01 Li + 0.01 The stoichiometric ratio of each element weighs 4.928g CaO, 1.533g BaO, 0.173g CeO 2 , 0.088g Li 2 CO 3 , fully ground and mixed, placed in a lead crucible, under ammonia gas (NH 3 ) in a reducing atmosphere, put it into a high-temperature tube furnace, bake at 1250°C for 6 hours, cool, grind, wash, and dry to get the chemical formula Ca 0.88 Ba 0.1 O:Ce 3+ 0.01 Li + 0.01 The yellow light phosphor powder is mixed with the organic silicon material at a weight ratio of 30%, coated on the blue light InGaN chip, and the white light emitting diode is obtained after potting and curing.

[0040] After testing, the color rendering index of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com