Method and device for continuously preparing high-silicon steel ribbon under magnetic field

A high-silicon steel and thin strip technology, applied in coatings, electrolytic coatings, etc., can solve the problems of inability to carry out large-scale production, poor silicon uniformity, poor process continuity, and poor density, and achieve stable and controllable production processes. Reduce production costs and have little impact on the original structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

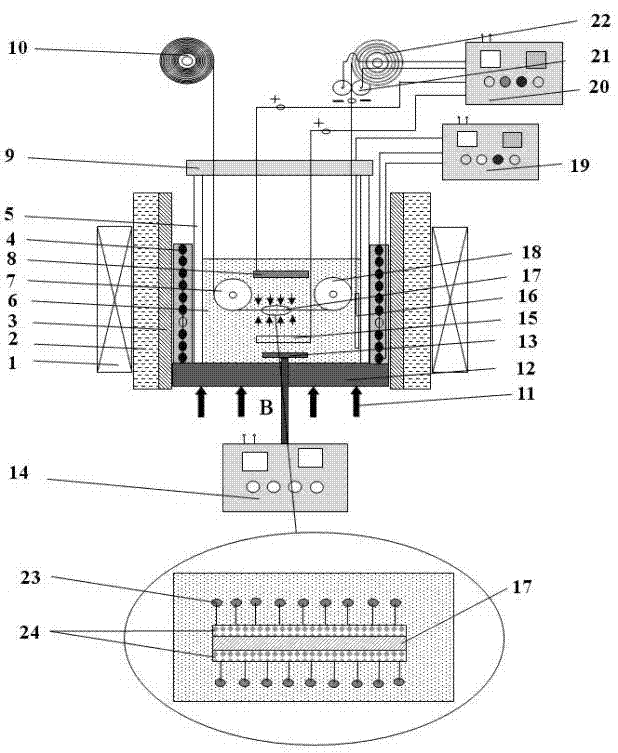

[0027] 1. A method for continuously preparing high-silicon steel thin strips under a magnetic field, which is characterized in that ferrosilicon alloy powder with a particle size of 0.1-3 μm and a relatively high silicon concentration-silicon content of 7.0-99wt% Si(23), is added with a special dispersant In the composite iron plating electrolyte, the low-silicon steel strip (17) with a silicon content of 0.1-4% Si is used as the cathode, and the pure iron sheet or low-silicon steel strip is used as the anode (8,15). When the low-silicon steel strip is continuously When passing through the middle of the double anode, the electroplating power supply (20) is turned on, and at the same time, the magnetization of the low-silicon steel thin strip cathode by an external magnetic field is used to form a strong magnetic field gradient and magnetic field force on the surface of the low-silicon steel thin strip cathode, and the composite iron plating electrolyte The fine ferrosilicon all...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, and the features are as follows:

[0035] 1. The magnetic field generation method of the constant magnetic field generator (1) is a permanent magnet, or an electromagnet, or a Bitter magnet, or a superconducting magnet, or a mixed magnet, and the magnetic induction is 0.001-20 Tesla (T) ;

[0036] 2. The low-silicon steel strip cathode (17) has a thickness of 0.05-0.5mm and a width of 10-2000mm.

[0037] 3. The stirring method of the electroplating solution (6) is mechanical stirring, or ultrasonic stirring, or stirring by acid pump circulation, so that the composition, temperature and composition of the electroplating solution (6) are homogenized.

[0038] 4. The composite plating process is carried out continuously, and the speed of the low-silicon steel strip cathode (17) is controlled at 0.01-10m / s; the distance between the cathode and the anode is kept at 0.5-10cm.

[0039] 5. The thickness of the composite i...

Embodiment 3

[0044] see figure 1 , a device for continuously preparing high-silicon steel thin strips under this magnetic field, applied to the above method, including

[0045] Constant magnetic field generator (1), water cooling device (2), heat insulating material (3), heating device (4), temperature-resistant electroplating tank (5), electroplating solution (6), front guide fixed pulley (7), pure iron On-chip anode (8), electroplating tank cover (9), high-silicon coated silicon steel strip winding mechanism (10), polytetrafluoroethylene bottom (12), mechanical stirring paddle (13), mechanical stirring control device (14), Pure iron lower anode (15), thermocouple (16), low-silicon steel strip cathode (17), rear guide fixed pulley (18), temperature controller (19), DC power supply (20), cathode electric nip roller (21 ), low-silicon steel delivery mechanism (22). The temperature-resistant electroplating tank (5) is placed on the polytetrafluoroethylene bottom plate (12), and the periph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com