High dielectric constant ceramic/polymer matrix composite dielectric material and preparation method thereof

A high dielectric constant and dielectric material technology, applied in the field of composite materials, can solve the problems of difficult to control the amount of addition and dielectric constant, poor engineering practicability, rapid changes, etc., to achieve engineering practicability, easy filling, high The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

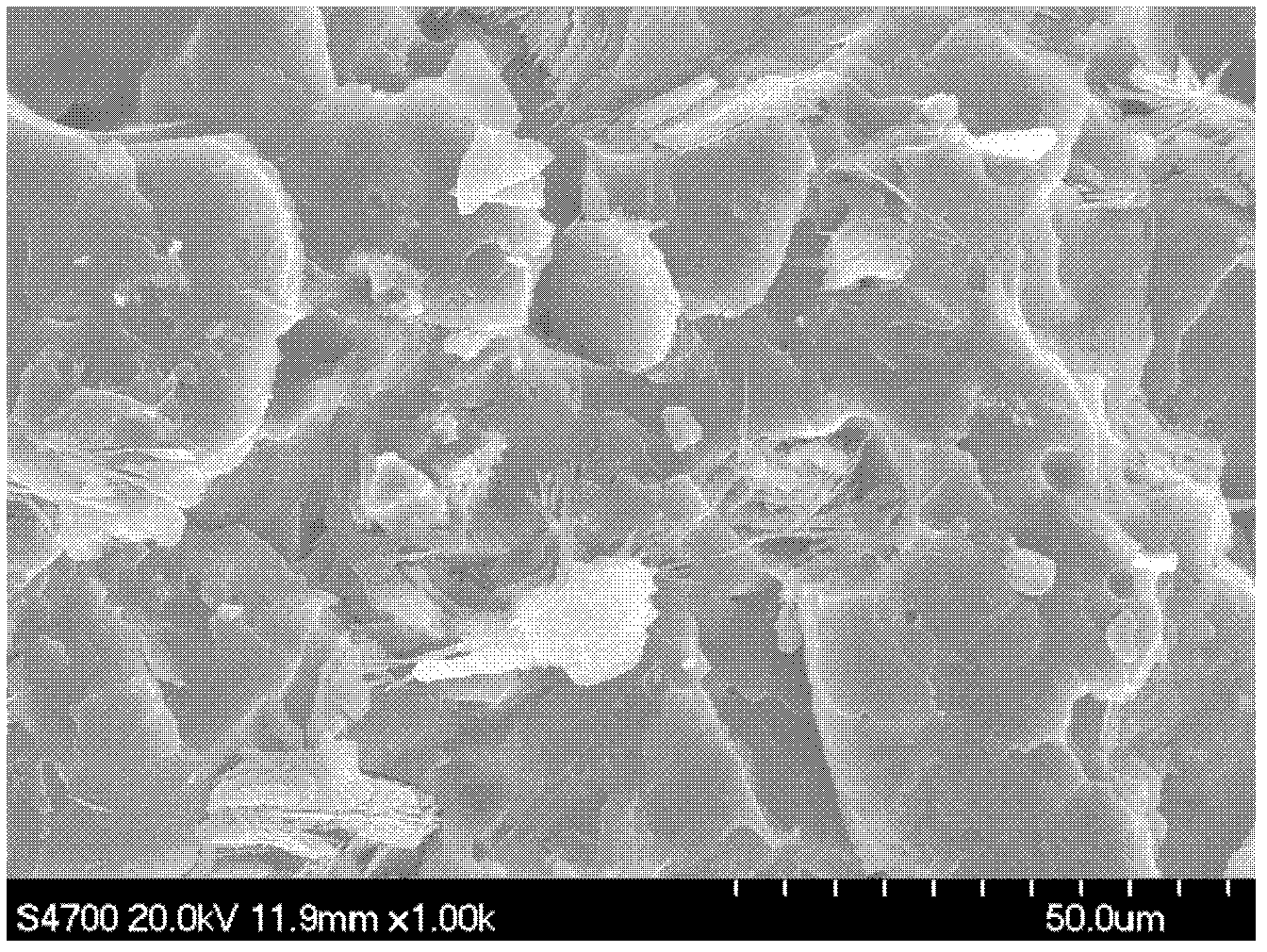

Image

Examples

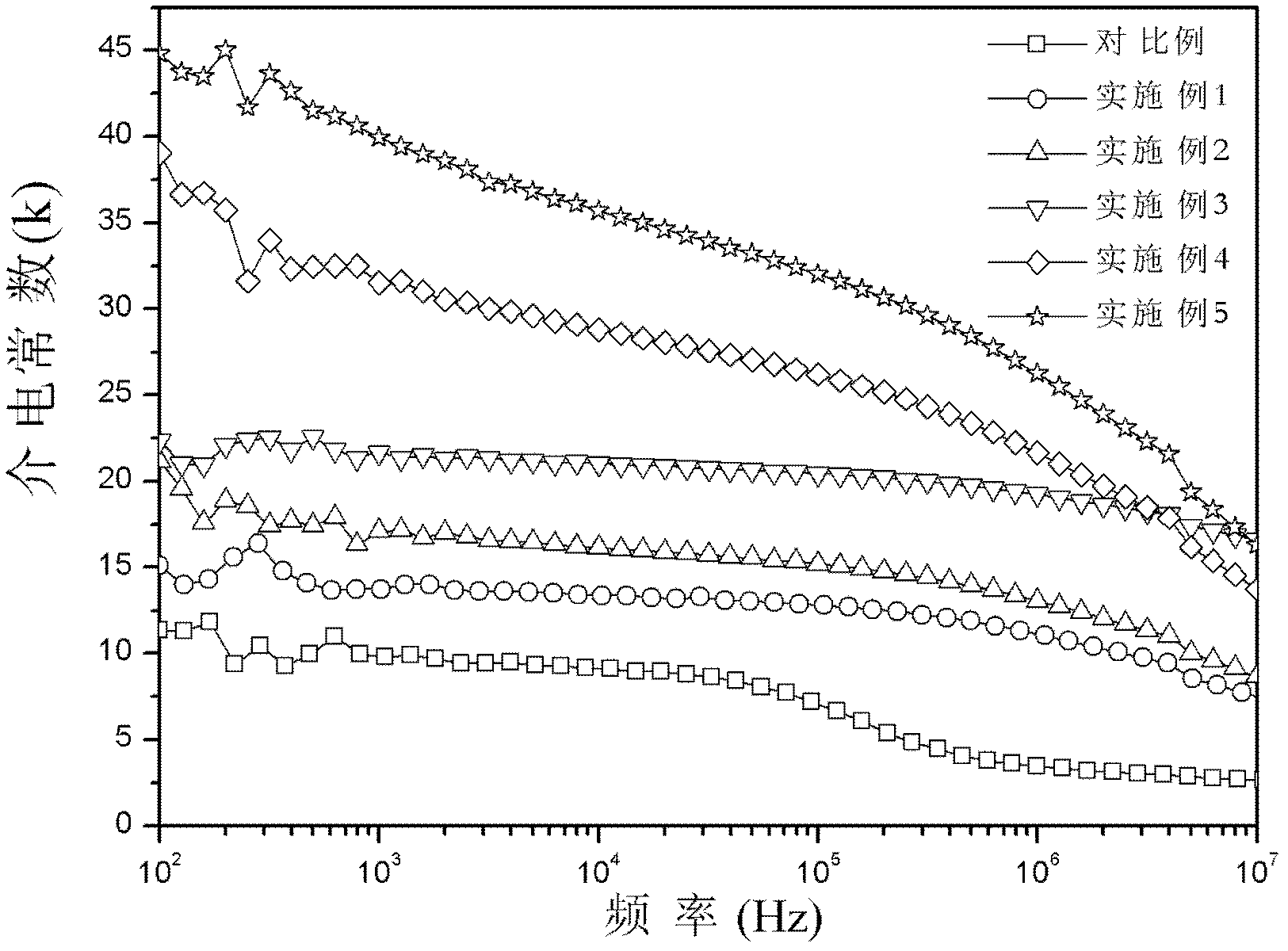

Embodiment 1

[0020] Measure the polyvinylidene fluoride and copper calcium titanate ceramic powder according to the volume ratio of 9:1; put the polyvinylidene fluoride and copper calcium titanate ceramic powder into a ball mill and mix and grind for 15 minutes, the ball-to-material ratio is 1:1 ;Put the polyvinylidene fluoride and copper calcium titanate ceramic mixed powder into the mold for hot pressing, the hot pressing temperature is 200°C, the pressure is 15MPa, the holding time is 15min, cool naturally, take out the sample, and get the copper calcium titanate ceramic mixed powder Composites with a powder volume fraction of 10%.

Embodiment 2

[0022] Measure the polyvinylidene fluoride and copper calcium titanate ceramic powder according to the volume ratio of 83:17; put the polyvinylidene fluoride and copper calcium titanate ceramic powder into a ball mill and mix and grind for 15 minutes, the ball-to-material ratio is 1:1 ;Put the mixed powder of polyvinylidene fluoride and copper calcium titanate ceramics into the mold for hot pressing, the hot pressing temperature is 200°C, the pressure is 15MPa, the holding time is 15min, cool naturally, take out the sample, and obtain copper calcium titanate ceramics The composite material was mixed with a powder volume fraction of 17%.

Embodiment 3

[0024] Measure the polyvinylidene fluoride and copper calcium titanate ceramic powder according to the volume ratio of 77:23; put the polyvinylidene fluoride and copper calcium titanate ceramic powder into a ball mill and mix and grind for 15 minutes, the ball-to-material ratio is 1:1 ;Put the polyvinylidene fluoride and copper calcium titanate ceramic mixed powder into the mold for hot pressing, the hot pressing temperature is 200°C, the pressure is 15MPa, the holding time is 15min, cool naturally, take out the sample, and get the copper calcium titanate ceramic mixed powder Composites with a powder volume fraction of 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com