Solar heater, and system and method for producing biodiesel by utilizing solar energy

A solar collector and biodiesel technology, applied in solar heating systems, solar thermal energy, solar collectors, etc., can solve problems such as heating of biodiesel feedstocks that have not been seen before, and achieve widening production areas, enhancing mobility, catalyzing Strong alkaline effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

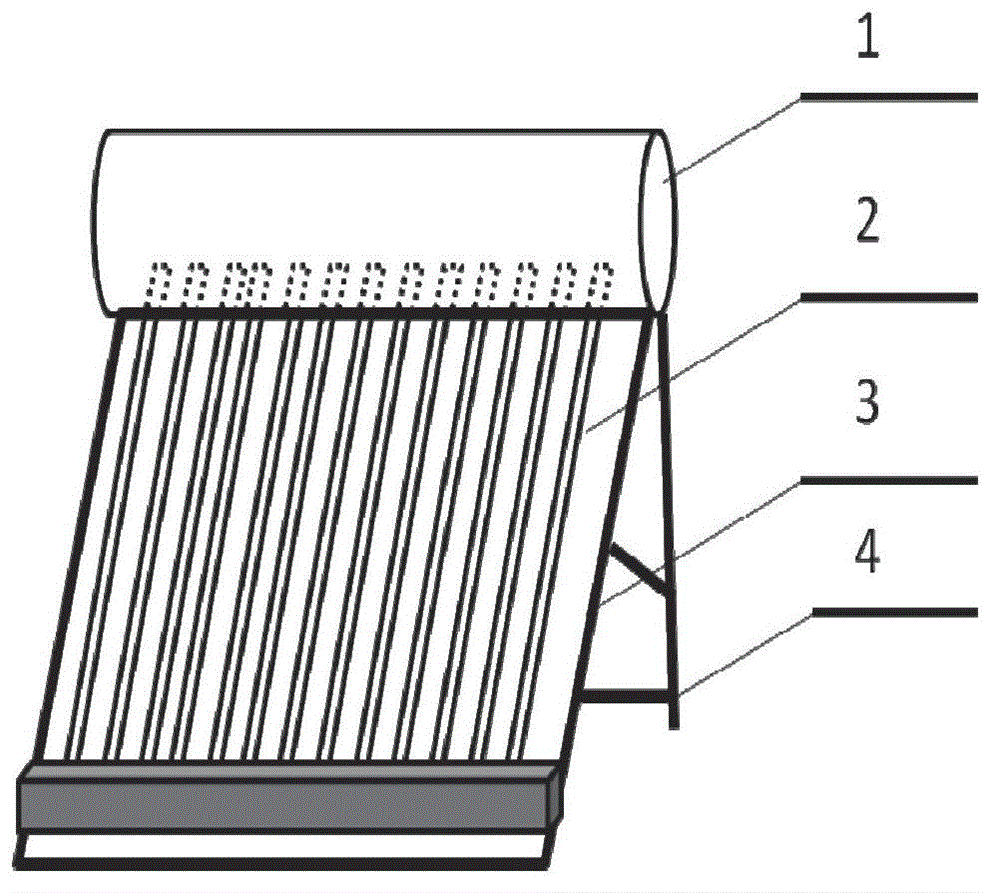

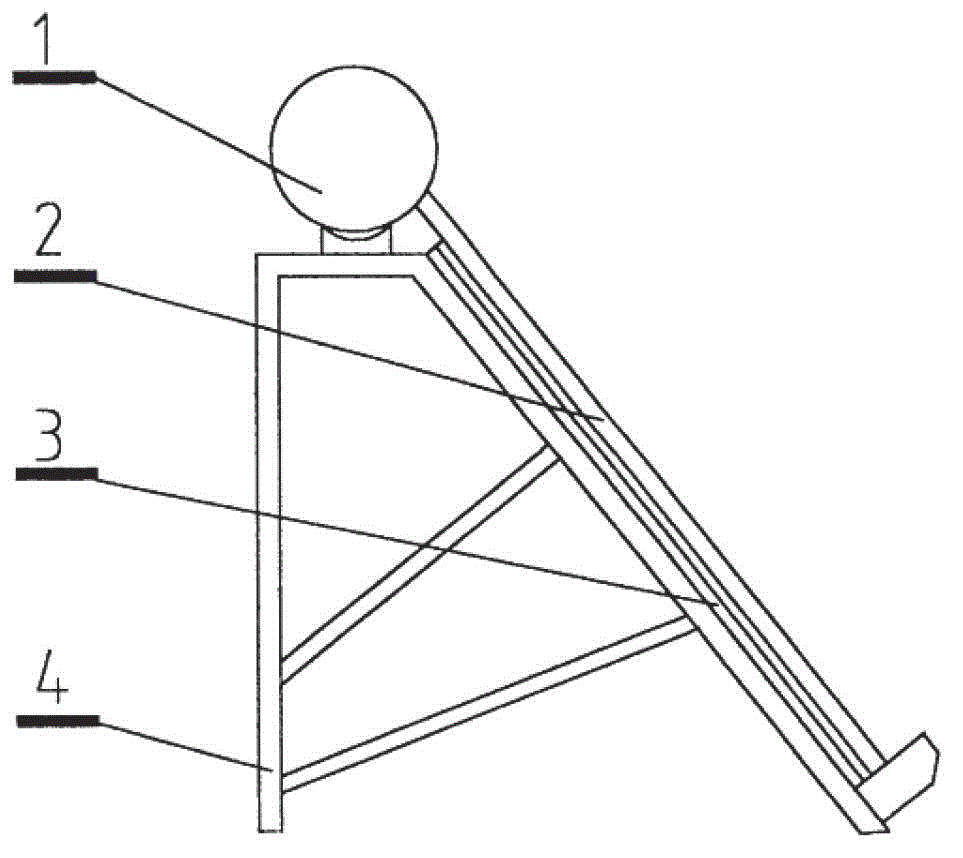

[0032]In this embodiment, the structure of the phase change thermal storage solar heater is as follows figure 1 , 2 As shown, it is composed of a phase change heat storage heater 1, a solar heat collector and a support 4 supporting the phase change heat storage heater and the solar heat collector. The structure of the phase change thermal storage heater 1 is as follows image 3 As shown, it includes an insulation box, a heat pipe 8, a heat exchange coil 7 and a phase change heat storage material; the insulation box is made of a cylindrical box 5-1 made of carbon steel and a polyurethane insulation layer coated on the outer wall of the box 5-2, the box wall is provided with a hole for pouring paraffin and rosin mixture, and is equipped with a hole plug 5-3; the heat pipe 8 is made of stainless steel 304, installed in the cylindrical box 5 -1 the lower part of the inner cavity; the heat exchange coil 7 is made of stainless steel 304, installed in the inner cavity of the cylind...

Embodiment 2

[0034] In this embodiment, the system for producing biodiesel using solar energy such as Figure 4 As shown, it includes the phase change thermal storage solar heater 11 described in Embodiment 1, the oil storage container 13 , the biodiesel equipment 15 , the circulation pump 12 , the control device 14 and the solar power source 16 .

[0035] The phase-change thermal storage type solar heater 11 is used to heat the grease raw material; the oil storage container 13 is provided with two oil inlets and two oil outlets, and is equipped with a liquid level gauge and a thermometer. The oil port is used to add unheated grease raw material, the first solenoid valve 131 is installed at the first oil inlet, and the second oil outlet is used to output the grease raw material heated to meet the temperature requirements, and the second oil outlet A second electromagnetic valve 132 is installed at the place, and the second electromagnetic valve is connected with the oil inlet of the biodie...

Embodiment 3

[0038] In this example, the system for producing biodiesel using solar energy described in Example 2 is used to produce biodiesel, the raw material of oil is jatropha oil, and the catalyst is calcium oxide. The preparation method of the catalyst is as follows: using calcium hydroxide as raw material, place the calcium hydroxide in a muffle furnace, calcinate at 800°C for 2 hours under normal pressure, then cool to room temperature with the furnace, take it out, and grind it with an 80-mesh sieve The calcium oxide powder obtained by screening is the catalyst.

[0039] In the present embodiment, the operation steps of producing biodiesel are as follows:

[0040] 1. Turn on the solar power supply 16 and the control device 14, under the control of the control device, add the rated jatropha oil in the oil storage container 13, and through the delivery of the circulation pump 12, make the oil raw material in the phase change regenerative solar heater The circulating flow between 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com