Linaclotide synthesis method

A technology of linaclotide and protecting group, which is applied in the field of synthesizing linaclotide, can solve the problems of process amplification, improvement of the purity of linear crude peptide, and increase of impurities, so as to achieve the improvement of crude product purity and yield, and increase the purity of linear crude peptide , the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

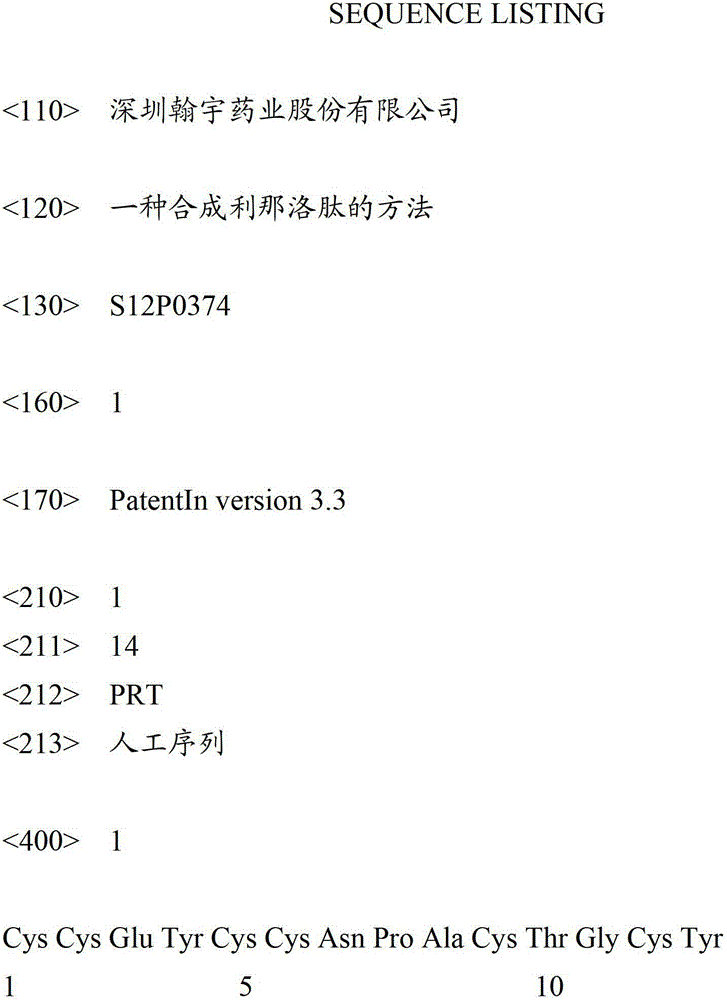

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of Fmoc-Tyr(tBu)-Wang Resin

[0037] Weigh 300g of Wang Resin with a substitution degree of 1.0mmol / g, add it to a solid-phase reaction column, wash it twice with DMF, and swell the resin with DMF for 30 minutes, add 206.8g of Fmoc-Tyr(tBu)-OH (450mmol), 72.9g HOBt (540mmol) and 5.50g DMAP (45mmol) were dissolved in DMF / DCM=1:1 (V / V) mixed solution, and 84.4mL DIPCDI (540mmol) was added under ice-water bath to activate for 5min, then the above-mentioned resin containing In the reaction column, after 2 hours of reaction. A mixture of 567.2ml acetic anhydride (6mol) and 482.2ml pyridine (6mol) was added to block for 12h. Wash with DMF for 3 times, DCM for 3 times, shrink and dry with methanol to obtain Fmoc-Tyr(tBu)-Wang Resin, the detection degree of substitution is 0.408mmol / g.

Embodiment 2

[0038] Embodiment 2: Preparation of Fmoc-Tyr(tBu)-Wang Resin

[0039] Weigh 300g of Wang Resin with a substitution degree of 1.0mmol / g, add it to a solid-phase reaction column, wash it twice with DMF, and swell the resin with DMF for 30 minutes, add 413.6g of Fmoc-Tyr(tBu)-OH (450mmol), 145.8g HOBt (540mmol) and 11.0g DMAP (45mmol) were dissolved in DMF / DCM=1:1 (V / V) mixture, and 168.8mL DIPCDI (1080mmol) was added under ice-water bath to activate for 5min, then the above-mentioned resin containing In the reaction column, after 2 hours of reaction. A mixture of 567.2ml acetic anhydride (6mol) and 482.2ml pyridine (6mol) was added to block for 12h. Wash with DMF for 3 times, DCM for 3 times, shrink and dry with methanol to obtain Fmoc-Tyr(tBu)-Wang Resin, the detection degree of substitution is 0.612mmol / g.

Embodiment 3

[0040] Embodiment 3: Preparation of Fmoc-Tyr(tBu)-Wang Resin

[0041] Weigh 300g of Wang Resin with a degree of substitution of 1.0mmol / g, add it to a solid-phase reaction column, wash it twice with DMF, and swell the resin with DMF for 30 minutes, add 344.6g of Fmoc-Tyr(tBu)-OH (750mmol) , 121.6g HOBt (900mmol), 9.2g DMAP (75mmol) were dissolved in DMF / DCM=1:1 (V / V) mixed solution, and 140.7mL DIPCDI (900mmol) was added under ice-water bath to activate for 5min, then the above-mentioned resin containing In the reaction column, after 2 hours of reaction. A mixture of 567.2ml acetic anhydride (6mol) and 482.2ml pyridine (6mol) was added to block for 12h. Wash with DMF for 3 times, DCM for 3 times, shrink and dry with methanol to obtain Fmoc-Tyr(tBu)-Wang Resin, the detection degree of substitution is 0.489mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com