Chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at low temperature

A nanocrystalline and sheet-like technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of high solvent toxicity, impure products, complicated processes, etc., and achieve convenient operation, uniform appearance and good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation: Flatten the analytically pure metal copper foil and put it into a beaker filled with dilute hydrochloric acid (concentrated hydrochloric acid and deionized water, volume ratio 1:201 and absolute ethanol solution, and clean it with an ultrasonic cleaner for 3 minutes. Soak in N,N-2 methylformamide for later use; wash the glass bottle (capacity 10ml) with tap water, distilled water, and absolute ethanol in sequence, and dry it for later use;

[0045] 2. Reaction steps: Weigh 0.01g of sulfur powder and put it in the glass bottle (capacity 10ml) prepared in step 1, then fill it with 8ml of N, N-dimethylformamide, keep the temperature in an ice-water bath for 1 hour, and then put the sulfur powder Pour it to the bottom side of the glass bottle, put the metal copper foil treated in step 1 into the glass bottle horizontally, avoid direct contact with sulfur powder, put the glass bottle in an ice-water bath to react in a stable place, and react at 0°C 18 hours; ...

Embodiment 2

[0048] 1, preparatory work: with embodiment 1;

[0049] 2. Reaction steps: Weigh 0.01g of sulfur powder and put it in the glass bottle (volume 10ml) prepared in step 1, then fill it with 8ml of N,N-dimethylformamide, keep the temperature in an ice-water bath for 1 hour, and then put the sulfur Pour the powder to the bottom side of the glass bottle, put the metal copper foil treated in step 1 into the glass bottle horizontally, avoid direct contact with the sulfur powder, put the glass bottle in an ice-water bath and react in a stable place, at 0°C Respond for 24 hours;

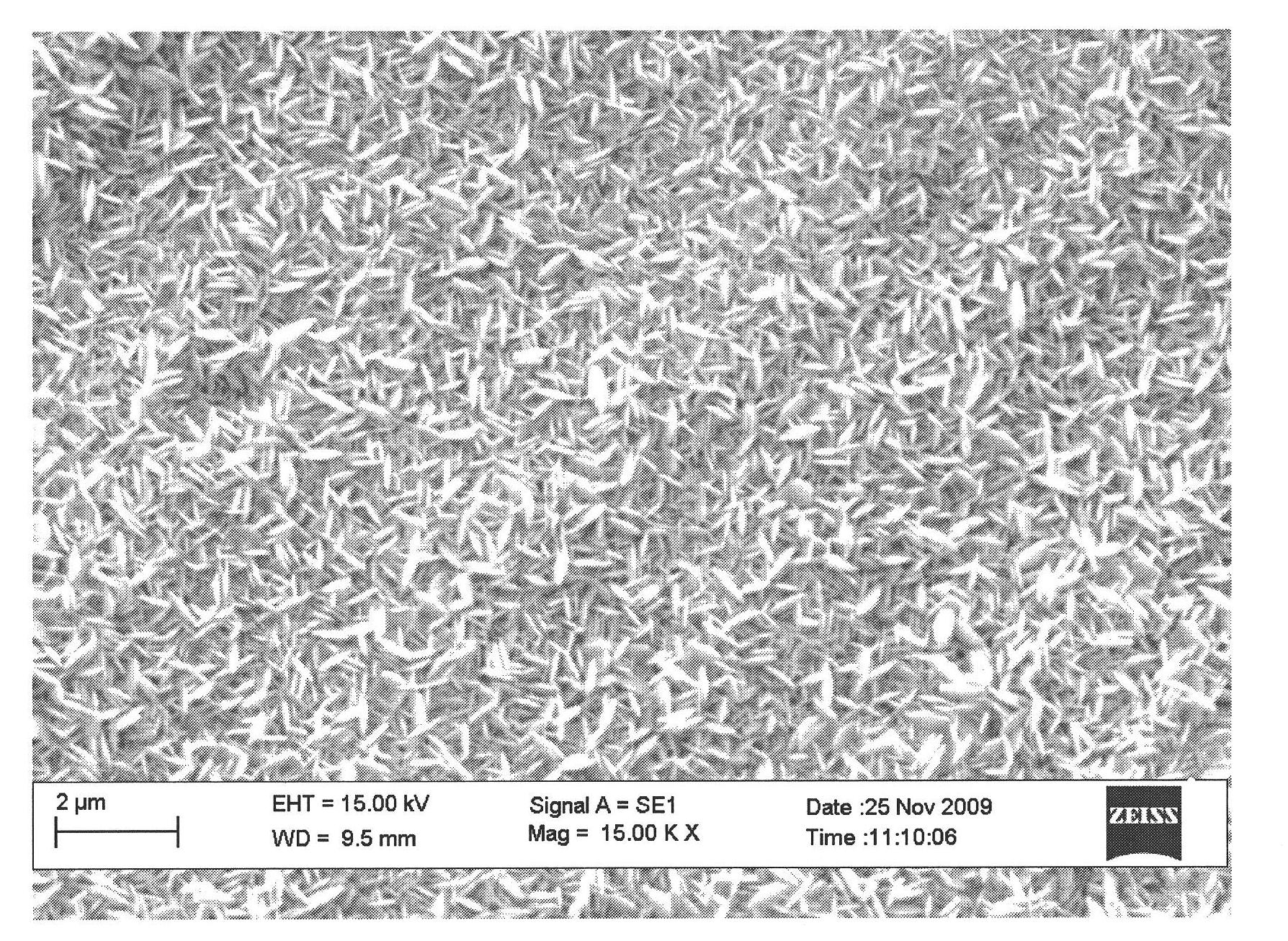

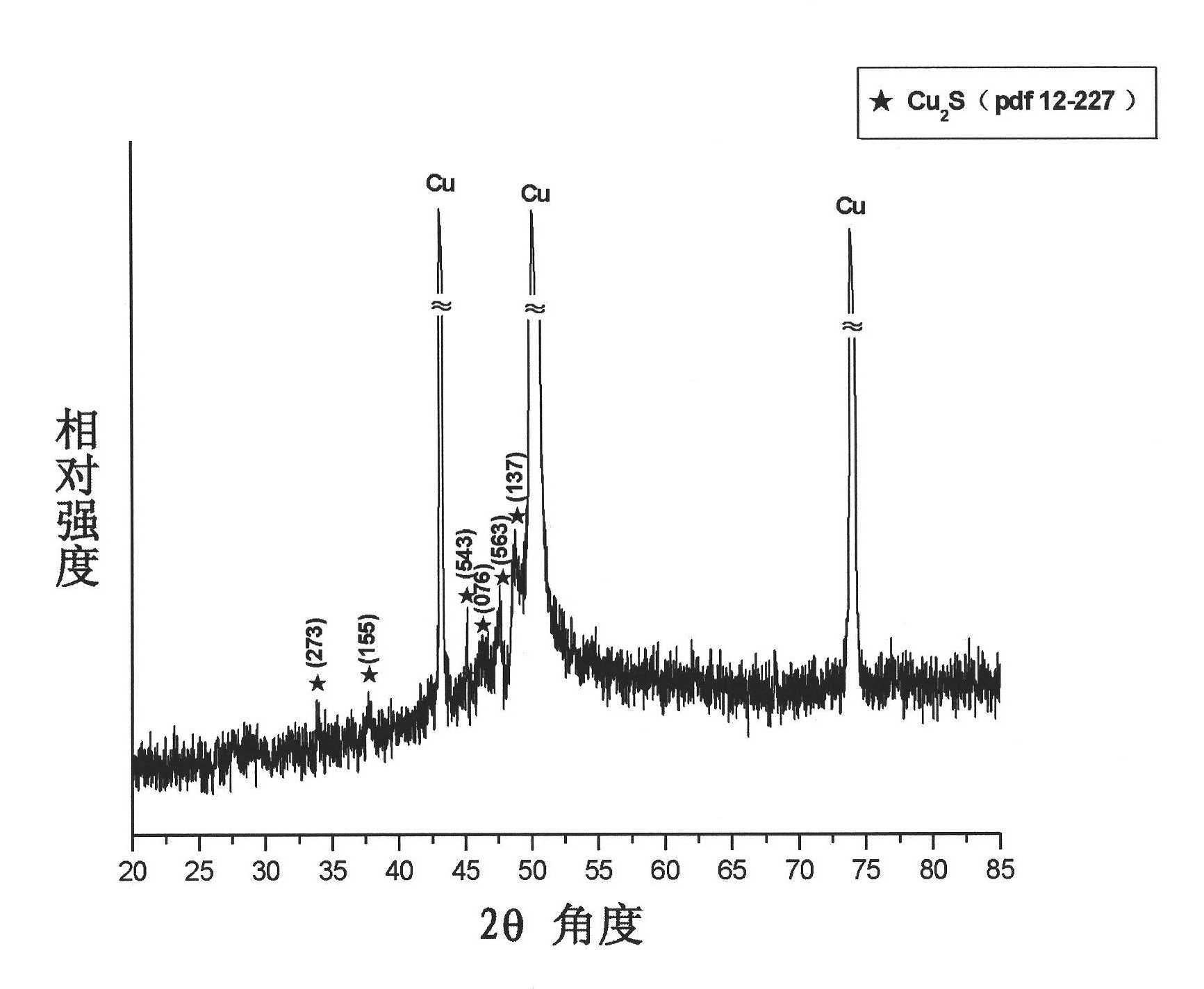

[0050] 3, aftertreatment: with embodiment 1, obtain Cu 2 S film samples. The color of the product is gray-black, and the microstructure under the scanning electron microscope is a large-area flaky nanocrystal with a uniform and flat surface. Scanning electron micrographs see diagram 2-1 , XRD pattern see Figure 2-2 .

Embodiment 3

[0052] 1, preparatory work: with embodiment 1;

[0053] 2. Reaction steps: Weigh 0.01g of sulfur powder and put it in the glass bottle (capacity 10ml) prepared in step 1, then fill it with 8ml of N,N-dimethylformamide, place it at 20°C for 1 hour, then put Pour the sulfur powder to the bottom side of the glass bottle, put the metal copper foil treated in step 1 into the glass bottle horizontally, avoid direct contact with the sulfur powder, place the glass bottle in a stable place for reaction, and react at 20°C for 8 hours ;

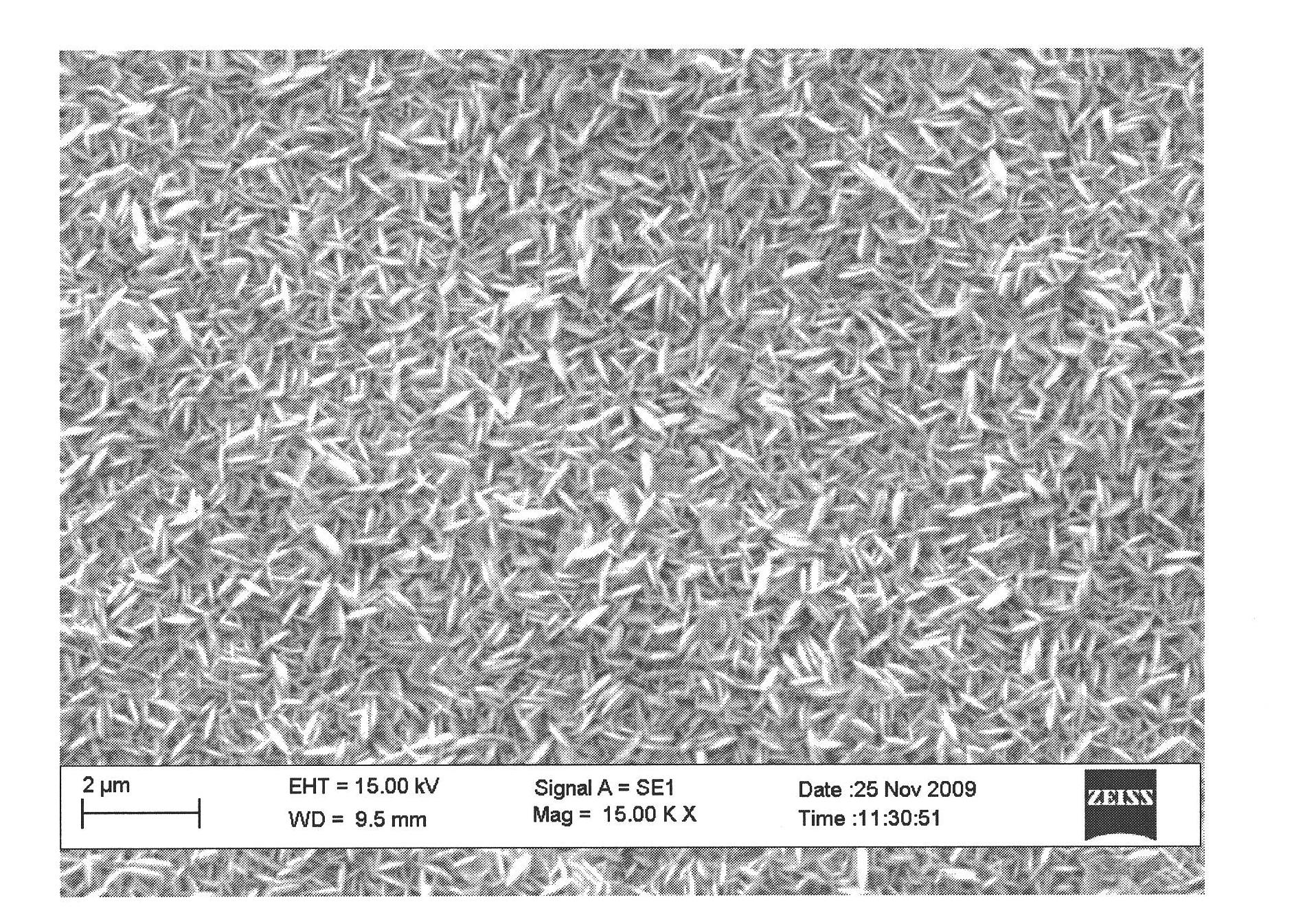

[0054] 3, aftertreatment: with embodiment 1, obtain Cu 8 S 9 and Cu 2 S two-phase mixed nanocrystalline film sample. The color of the product is blue-black, and the microstructure under the scanning electron microscope is a large-area flaky nanocrystal with a uniform and flat surface. Scanning electron micrographs see Figure 3-1 , XRD pattern see Figure 3-2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com