A kind of gear and its manufacturing method

A manufacturing method and gear technology, applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of low material utilization, high product cost, low production efficiency, etc., and achieve high product quality , high production efficiency and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

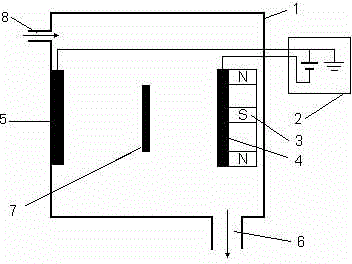

Image

Examples

Embodiment 2

[0046] The difference from Example 1 is that the silicon-aluminum alloy substrate is different, and this example is A390, see Table 1;

[0047] The network skeleton components are different, see Table 2;

[0048] Stainless steel wire diameters are different, see Table 2;

[0049] The mold is heated to 300°C, the pre-forging temperature is 450°C, the final forging temperature is 380°C, and the upper die speed is 150mm / s.

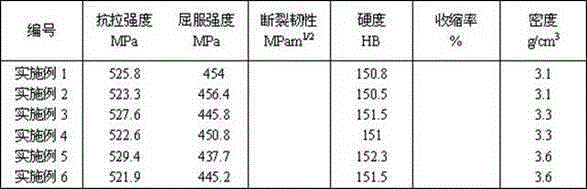

[0050] The performance parameters after forming are shown in Table 3.

Embodiment 3

[0052] It is basically the same as Example 1, the difference is:

[0053] Stainless steel wire diameters are different, see Table 2;

[0054] The volume fraction of reinforcement is different, see Table 2;

[0055] The impregnation temperature is different, see Table 2;

[0056] The die is heated to 400°C, the pre-forging temperature is 480°C, the final forging temperature is 400°C, and the upper die speed is 200mm / s.

[0057] The performance parameters after forming are shown in Table 3.

Embodiment 4

[0059] It is basically the same as Example 1, except that: the network skeleton components are different, see Table 2;

[0060] Stainless steel wire diameters are different, see Table 2;

[0061] The volume fraction of reinforcement is different, see Table 2;

[0062] The impregnation temperature is different, see Table 2;

[0063] 10000KN friction press is used to precision forge the side shaft gear.

[0064] The performance parameters after forming are shown in Table 3.

[0065] Table 1

[0066]

[0067] Table 2

[0068]

[0069] table 3

[0070]

[0071] To sum up, the gear provided by the present invention has the advantages of excellent performance, reasonable process, moderate price, high strength, small specific gravity, etc., and the fracture toughness of the material is further improved through the network braided skeleton, which can replace the existing non-ferrous metal profiles and expand The scope of use meets the needs of actual production,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com