Organic silicon modified epoxy floor paint and preparation method and application thereof

A silicone epoxy and epoxy flooring technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of not being able to effectively improve the stain resistance of coatings for a long time, unfavorable promotion and application of floor coatings, and high raw material prices. Achieve the effects of improving impact resistance, reducing production costs, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

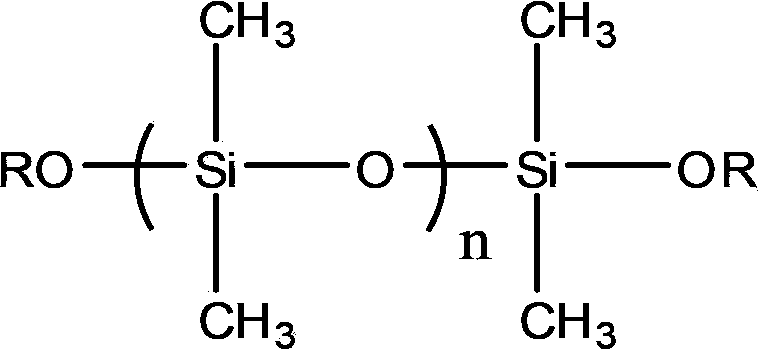

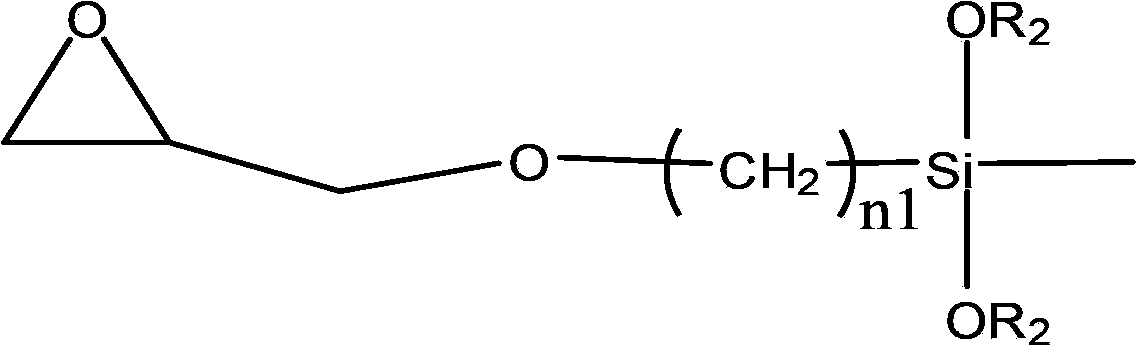

[0056](1) Preparation of silicone epoxy compound: 5g of γ-(2,3-glycidoxy)propyltrimethoxysilane, 100g of polydimethylsiloxane (n=1500), 0.03g of water , 50 g of toluene, catalyzed by 0.01 g of triethylamine, hydrolysis and condensation reaction at 50 ° C for 8 hours, rotary evaporation to remove toluene, to obtain organosilicon epoxy compound. In the FT-IR of the product, 910cm -1 The absorption peak of epoxy group appears on the left and right, 3400cm -1 The absorption peaks of the left and right polysiloxane terminal hydroxyl groups disappeared, indicating the formation of silicone epoxy compounds.

[0057] (2) Preparation of silicone modified epoxy floor coating: 100g of bisphenol A epoxy resin (epoxy value: 0.51mol / 100g), 20g of silicone epoxy compound prepared in step (1), 15g of epoxy Propane butyl ether, 50g montmorillonite, 2g dispersant BYK-P104, 25g polyamine 4,4-diaminodiphenylmethane, 1g leveling agent EFKA3777, 0.5g defoamer BYK066, 2g carbon black, 10g butyl A...

Embodiment 2

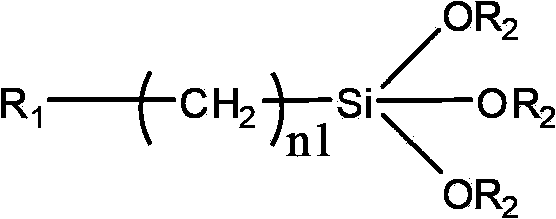

[0059] (1) Preparation of silicone epoxy compound: 30g of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane, 100g of polydimethylsilane (n=500), 5g of water, Under the catalyst of 0.2 g of tin dilaurate dibutylate, the hydrolysis condensation reaction is carried out at 130 DEG C for 2 hours to obtain the organosilicon epoxy compound for epoxy floor coating. In the FT-IR of the product, 910cm -1 The absorption peak of epoxy group appears on the left and right, 3400cm -1 The absorption peaks of the left and right polysiloxane terminal hydroxyl groups disappeared, indicating the formation of silicone epoxy compounds.

[0060] (2) Preparation of silicone modified epoxy floor coating: 50g bisphenol F epoxy resin (epoxy value: 0.51mol / 100g), 50g bisphenol A epoxy resin (epoxy value: 0.54mol / 100g) 100g), 30g silicone epoxy compound prepared above, 8g lauryl fatty alcohol glycidyl ether, 100g silicon dioxide, 5g dispersant BYK-P105, 30g polyetheramine (D230), 1g imidazole, 3g leveling Ag...

Embodiment 3

[0062] (1) Preparation of silicone epoxy compound: 10g of γ-(2,3-glycidoxy)propyltrimethoxysilane, 100g of polydimethylsilane (n=50), 2.5g of water, 50g of tetrahydrofuran , under the catalysis of 0.3g catalyst zinc chloride, hydrolysis and condensation reaction at 100 ° C for 3 hours, rotary evaporation to remove tetrahydrofuran, in the FT-IR of the product, 910cm -1 The absorption peak of epoxy group appears on the left and right, 3400cm -1 The absorption peaks of the left and right polysiloxane terminal hydroxyl groups disappeared, indicating the formation of silicone epoxy compounds.

[0063] (2) Preparation of silicone-modified epoxy floor coating: 100g novolac epoxy resin (epoxy value: 0.51mol / 100g), 0.1g silicone epoxy compound prepared above, 5g propylene oxide benzyl ether , 40g talcum powder, 40g kaolin, 0.5g dispersant BYK-P104, 50g polyaminoamide (G640), 0.5g 2-ethyl-4-methylimidazole, 2g leveling agent EFKA3777, 0.5g defoamer BYK066, 4g of chrome yellow and 30g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com