Cobaltosic oxide columnar structure material and preparation method thereof

A technology of tricobalt tetroxide and columnar structure, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of uneven appearance, low purity, and low yield of solvothermal method, and achieve uniform dispersion, high purity, and easy large-scale The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

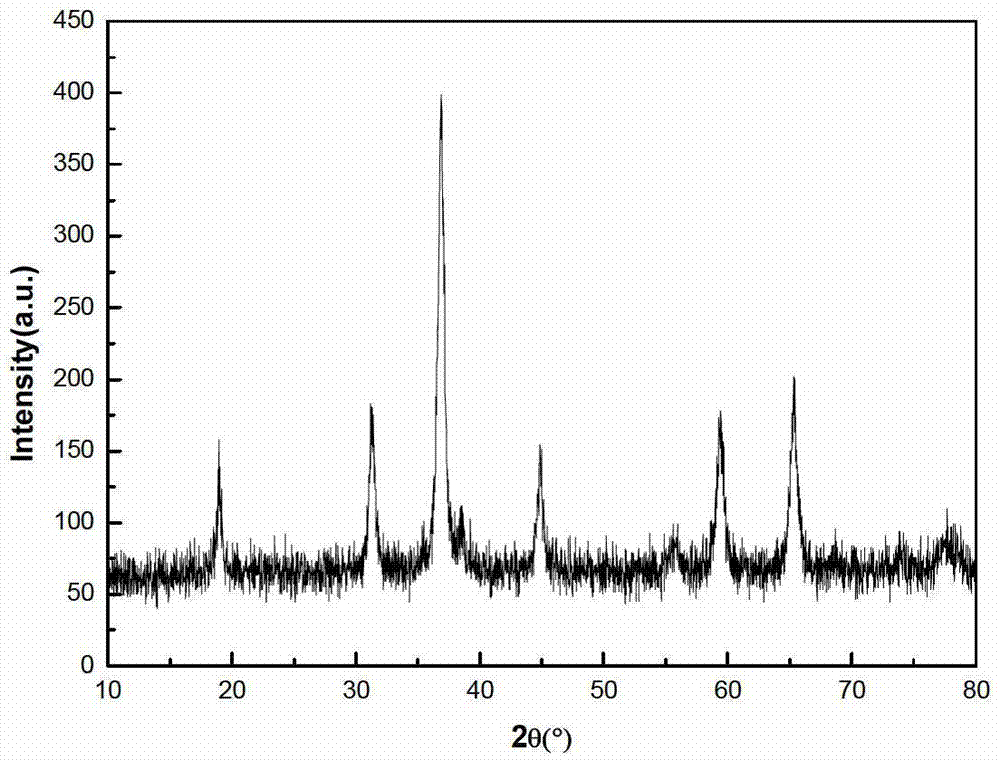

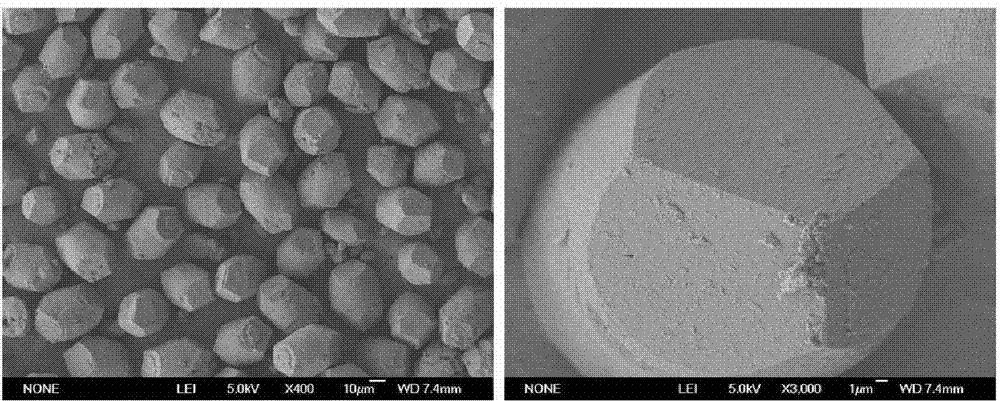

Embodiment 1

[0048] Accurately weigh 5mmol of cobalt acetate, add it to 20ml of distilled water and stir mechanically for 10 minutes to fully dissolve the cobalt acetate, then add 10ml of glycerol into the cobalt acetate solution and mechanically stir for 20 minutes, accurately weigh Dissolve 5 mmol of urea into the above mixed solution and mechanically stir for 1 hour, put the uniformly dispersed mixed solution into an autoclave and seal it, keep it at a reaction temperature of 150°C for 5 hours, and then wash it with distilled water and absolute ethanol for 5 hours. First, dry at 80°C for 12 hours in a vacuum drying oven to obtain a cobalt carbonate precursor with a columnar structure, and place the precursor in a muffle furnace for calcination at 350°C for 3 hours to obtain a columnar structure cobalt tetroxide material with a particle diameter of 8~10μm, the cobalt content in the particles is 74.31~74.48%.

Embodiment 2

[0050] Accurately weigh 6.5mmol of cobalt acetate, add it to 25ml of distilled water and mechanically stir for 10 minutes to fully dissolve the cobalt acetate, then add 5ml of glycerol into the cobalt acetate solution and mechanically stir for 20 minutes, accurately Weigh 5mmol of urea and dissolve it into the above mixed solution and stir it mechanically for 2 hours, put the uniformly dispersed mixed solution into an autoclave and seal it, keep it at a reaction temperature of 160°C for 15 hours, and then wash it with distilled water and absolute ethanol respectively 5 times, dry in a vacuum oven at 80°C for 20 hours to obtain a cobalt carbonate precursor with a columnar structure, and place the precursor in a muffle furnace for calcination at 250°C for 3 hours to obtain a columnar structure cobalt tetroxide material with a particle size of 9~ 12μm, the cobalt content in the particles is 74.35~74.50%.

Embodiment 3

[0052] Accurately weigh 7.5mmol of cobalt acetate, add it to 20ml of distilled water and stir mechanically for 10 minutes to fully dissolve the cobalt acetate, then add 10ml of glycerol into the cobalt acetate solution and mechanically stir for 20 minutes, accurately Weigh 5mmol of urea and dissolve it into the above mixed solution and stir it mechanically for 1 hour, put the uniformly dispersed mixed solution into an autoclave and seal it, keep it at a reaction temperature of 180°C for 5 hours, and then wash it with distilled water and absolute ethanol respectively 5 times, dry in a vacuum oven at 60°C for 24 hours to obtain a cobalt carbonate precursor with a columnar structure, and place the precursor in a muffle furnace for calcination at 400°C for 3 hours to obtain a columnar structure cobalt tetroxide material with a particle size of 8~ 9μm, the cobalt content in the particles is 74.32~74.49%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com