Method for recovery and granulation of high performance glass fiber reinforced liquid crystalline polymer secondary material

A technology of liquid crystal polymer and secondary material, which is applied in the field of high-performance glass fiber reinforced liquid crystal polymer secondary material recycling and granulation, and can solve the problems affecting the use of glass fiber reinforced liquid crystal polymer granulation material and the melt of the machine head die mouth Breakage, large twin-screw extrusion capacity, etc., to achieve the effect of not being prone to shear thinning, stable material flow performance, and small shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

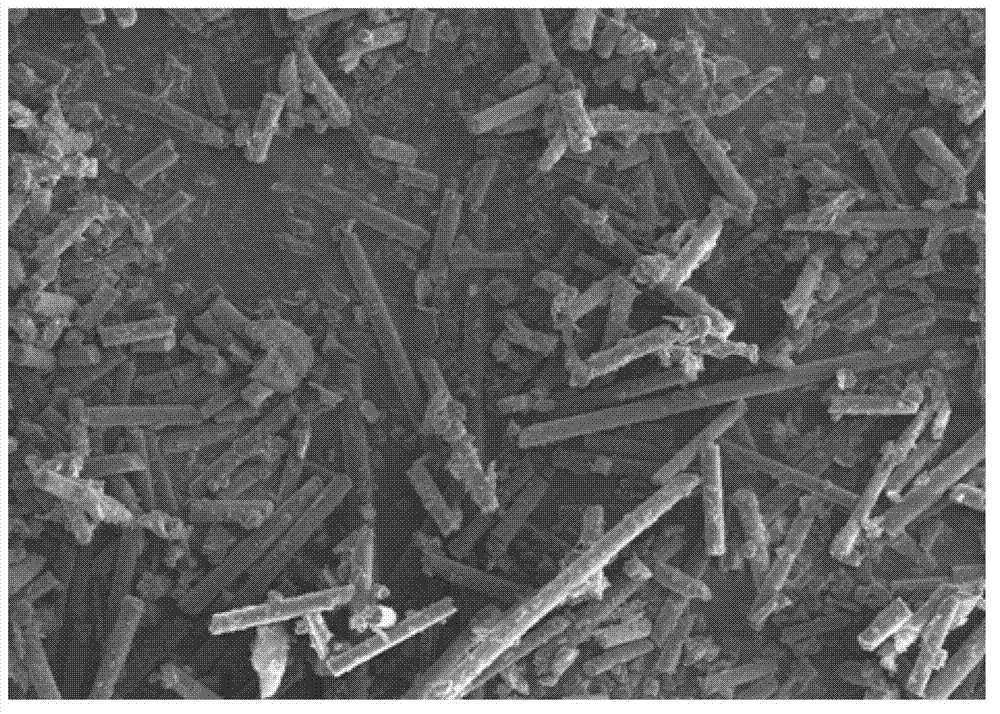

Embodiment 1

[0052] According to the above method, after crushing 200 kg of the secondary material to be recycled (LCP-6130), it is extruded through a single-screw extruder. 3.1, the number of die holes: 2 holes, the hole diameter is 3.5mm, the extrusion temperature is 335~375℃, the screw speed is 85rpm; Weigh the obtained LCP-6130 pellets (that is, the obtained recycled pellets) and the LCP-6130 pellets that cannot be pelletized due to broken bars and agglomerates during the extrusion process. Weigh 15 kg of LCP-6130 pellets at 130 ℃ drying for 4 hours, injection molding into various standard splines at an injection temperature of 335~375 ℃.

Embodiment 2

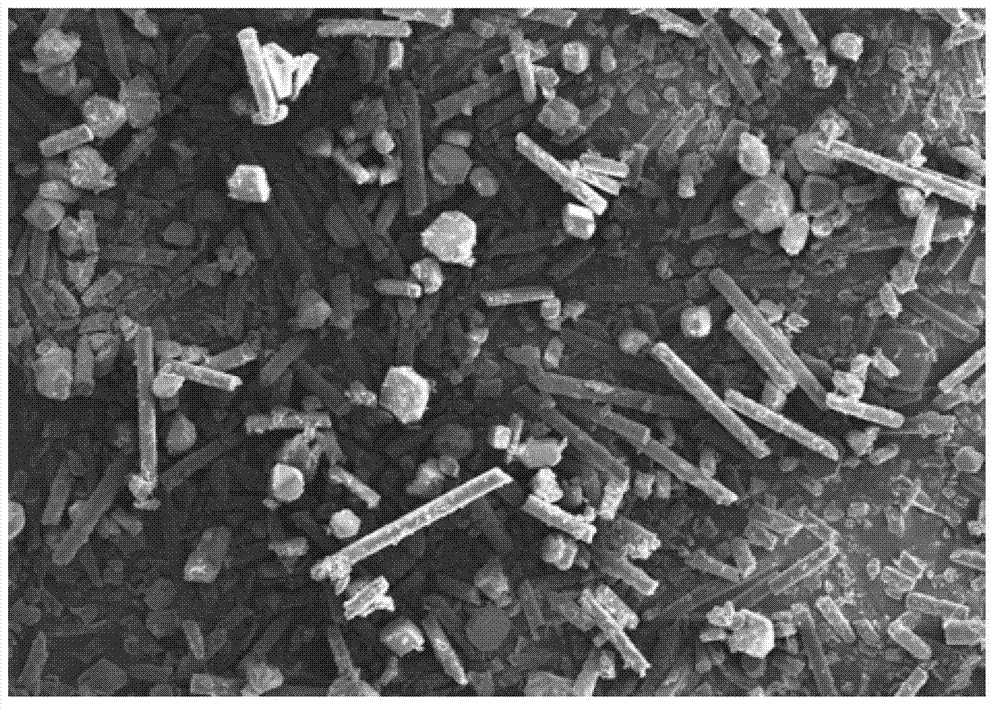

[0054] According to the above method, after crushing 200 kg of the secondary material to be recycled (LCP-6130), it is extruded through a single-screw extruder. 3.2, Number of die holes: 2 holes, hole diameter is 3.5mm, extrusion temperature is 335~375°C, screw speed is 125rpm; die opening has 2 holes, hole diameter is 3.0mm, the strands are cooled by water and then processed by pelletizer Pelletize, weigh the obtained LCP-6130 pellets (that is, the obtained recycled pellets) and the LCP-6130 materials that cannot be pelletized due to broken bars and agglomerates during the extrusion process, and weigh 15 kg of LCP-6130 pellets The material is dried at 130°C for 4 hours, and injected into various standard splines at an injection temperature of 335-375°C.

Embodiment 3

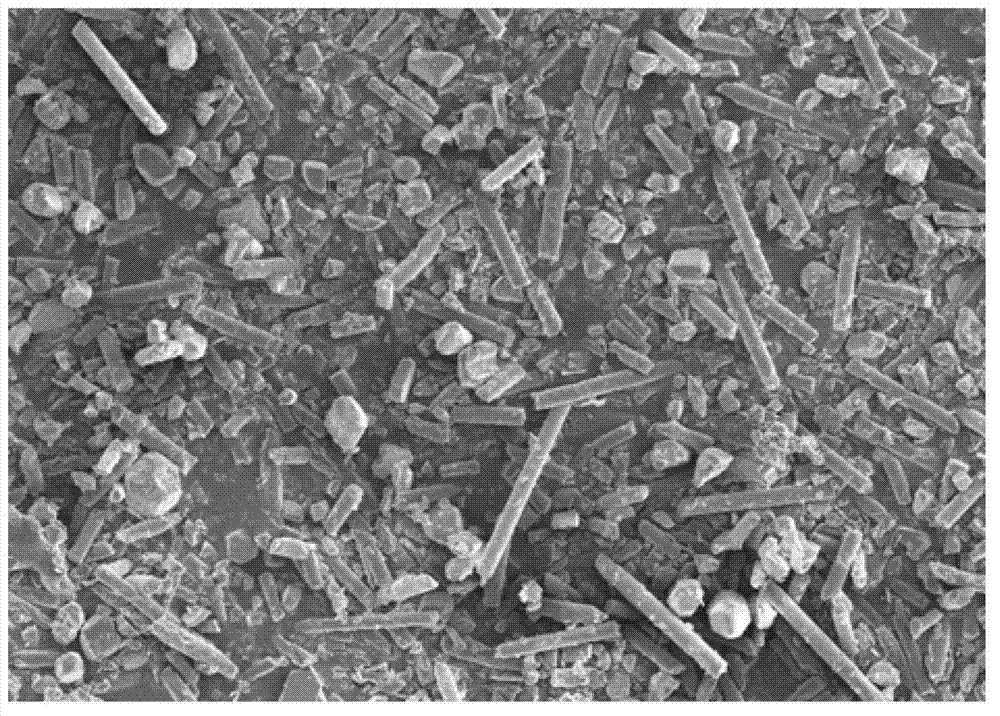

[0056] According to the above method, after crushing 200 kg of the secondary material to be recycled (LCP-6130), it is extruded through a single-screw extruder. 3.1, the number of die holes: 4 holes, the hole diameter is 3.4mm, the extrusion temperature is 335~375°C, the screw speed is 65rpm; the strands are water-cooled and then pelletized by a pelletizer to obtain LCP-6130 pellets The material (that is, the obtained recycled pellets) and the LCP-6130 material that cannot be pelletized due to broken bars and agglomerates during the extrusion process were weighed, and 15 kg of LCP-6130 pellets were weighed and dried at 130 ° C for 4 hours. Injection molded into various standard splines at an injection temperature of 335~375°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com