Metallized film capacitor, method for manufacturing same, and metallized film laminate

A metallized film and metallized film technology, applied in the field of capacitors, can solve the problems of shortening the life of metallized film capacitors, poor heat resistance and mechanical properties, and low film energy storage density, etc., and achieve long service life and heat resistance. And the effect of good mechanical properties and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

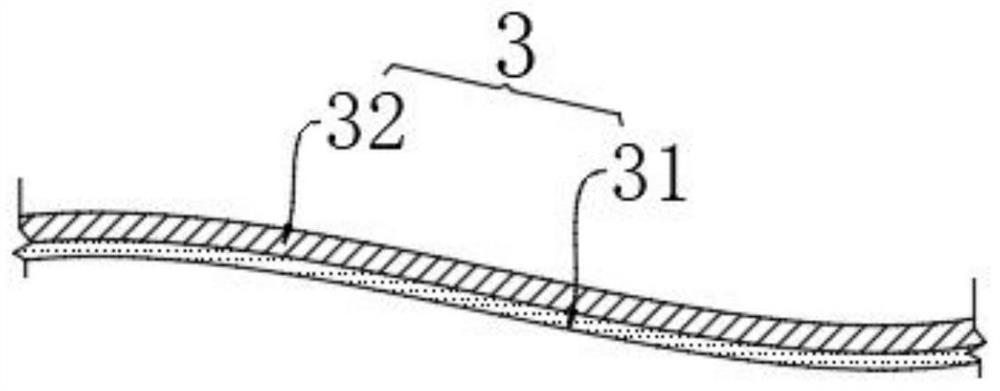

[0036] see figure 2 As shown, the metallized thin film laminate described in this embodiment includes a plurality of stacked metallized films 3, the metallized film 3 is composed of an organic plastic film 31 and an energy storage film 32 arranged on the surface of the organic plastic film 31, Different from the prior art, the organic plastic film 31 is a biphenyl type polyarylether nitrile film, which consists of the following components in parts by weight: 0.1 mol of biphenol, 0.1 mol of 2,6-dichlorobenzonitrile, Anhydrous potassium carbonate 0.12mol and auxiliary solvent 180mL, the auxiliary solvent is composed of the following components by weight: N-methylpyrrolidone 150mL, toluene 30mL;

[0037] The preparation of organic plastic film 31 comprises the following steps:

[0038] S1: Add biphenol, 2,6-dichlorobenzonitrile, anhydrous potassium carbonate, N-methylpyrrolidone and Toluene, under the protection of nitrogen, azeotropic dehydration for 2 hours, toluene was dist...

Embodiment 2

[0053] see figure 2 As shown, the metallized thin film laminate described in this embodiment includes a plurality of stacked metallized films 3, the metallized film 3 is composed of an organic plastic film 31 and an energy storage film 32 arranged on the surface of the organic plastic film 31, Different from the prior art, the organic plastic film 31 is a biphenyl type polyarylether nitrile film, which consists of the following components in parts by weight: 0.12 mol of biphenol, 0.12 mol of 2,6-dichlorobenzonitrile, Anhydrous potassium carbonate 0.14mol and auxiliary solvent 200mL, the auxiliary solvent is composed of the following components by weight: N-methylpyrrolidone 160mL, toluene 40mL;

[0054] The preparation of organic plastic film 31 comprises the following steps:

[0055] S1: Add biphenol, 2,6-dichlorobenzonitrile, anhydrous potassium carbonate, N-methylpyrrolidone and Toluene, under the protection of nitrogen, azeotropic dehydration for 2 hours, toluene was di...

Embodiment 3

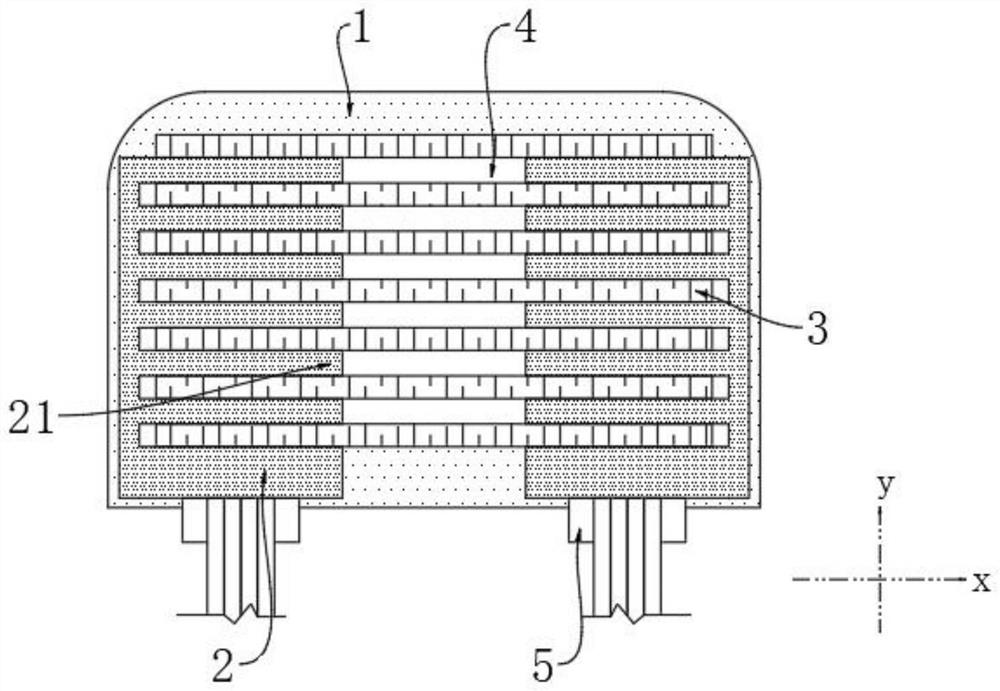

[0070] see figure 1 As shown, the metallized film capacitor described in this embodiment includes an epoxy resin 1 and electrical terminals 2 symmetrically arranged on both sides of the epoxy resin 1. Different from the prior art, the interior of the epoxy resin 1 is also provided with There are a plurality of metallized films 3 arranged equidistantly, and one side of the electric terminal 2 is provided with a plurality of convex strips 21, and the convex strips 21 and the metallized films 3 are alternately arranged, and the adjacent metallized films 3 and the convex strips A closed heat dissipation cavity 4 is formed between the strips 21, and a sealing sleeve 5 is fixedly arranged in the contact area between the electrical terminal 2 and the epoxy resin 1, and the sealing sleeve 5 is used for the contact area between the electrical terminal 2 and the epoxy resin 1 sealed and waterproof;

[0071] When in use, after the terminal 2 is connected to electricity, the charge is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com