High-strength plastic

A high-strength plastic, weight percentage technology, applied in the field of high-strength plastics, can solve the problems of low surface adsorption, fracture or crack, and less color change of high-strength plastics, achieve high flexural modulus, improve performance, and improve adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

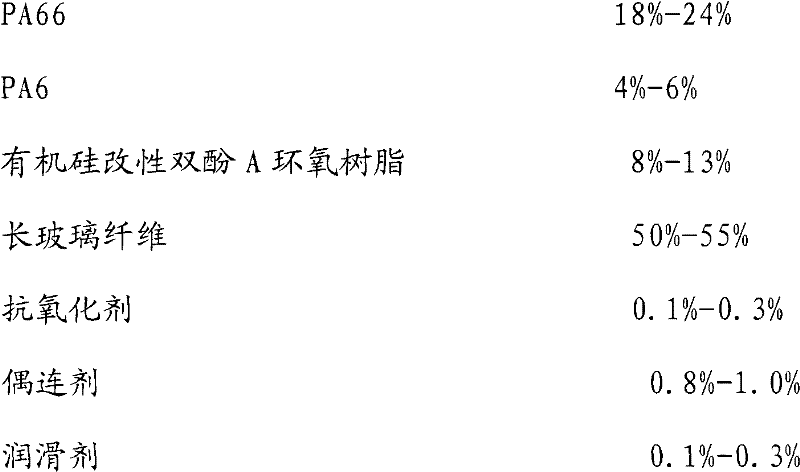

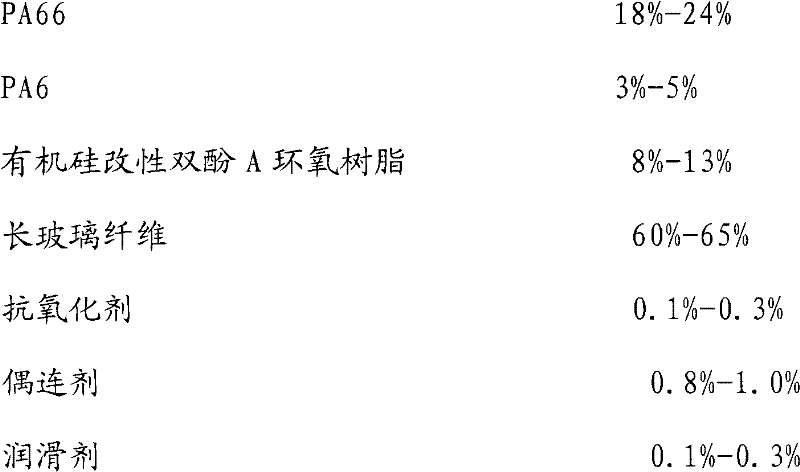

Method used

Image

Examples

Embodiment 1

[0025] Will be 21% PA66 by weight percentage, 6% PA6, 12% organosilicon modified bisphenol A epoxy resin, 0.1% antioxidant, 0.8% coupling agent, 0.1% lubricant puts 100Kg altogether Put it into a reactor with agitator and constant temperature function, keep the temperature of the reactor at 27°C-30°C, stir for 4-6 minutes with the agitator at 800-1200 rpm; then use twin-screw extrusion Machine melt extrusion, the processing temperature is 270°C-300°C; add 60% long glass fiber in the middle of extrusion. In order to ensure the proportion of long glass fibers added, a weight measuring device is installed in the middle of the extrusion, which can monitor the weight change and make adjustments. This device is used in the following examples of the present invention.

Embodiment 2

[0027] Will be 18% PA66 by weight percentage, 4% PA6, 12.4% organosilicon modified bisphenol A epoxy resin, 0.3% antioxidant, 1.0% coupling agent, 0.3% lubricant put 100Kg altogether Put it into a reactor with agitator and constant temperature function, keep the temperature of the reactor at 27°C-30°C, stir for 4-6 minutes with the agitator at 800-1200 rpm; then use twin-screw extrusion Machine melt extrusion, the processing temperature is 270°C-300°C; add 64% long glass fiber in the middle of extrusion.

Embodiment 3

[0029] Will be 20.6% PA66 by weight percentage, 5% PA6, 8% organosilicon modified bisphenol A epoxy resin, 0.2% antioxidant, 1.0% coupling agent, 0.2% lubricant puts 100Kg altogether Put it into a reactor with agitator and constant temperature function, keep the temperature of the reactor at 27°C-30°C, stir for 4-6 minutes with the agitator at 800-1200 rpm; then use twin-screw extrusion Machine melt extrusion, the processing temperature is 270°C-300°C; add 65% long glass fiber in the middle of extrusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com