Method for measuring torque of low temperature superconductive wire, and apparatus thereof

A low-temperature superconductivity and wire technology, which is used in measurement devices, power measurement, and analysis of materials, etc., can solve the problems of complicated shooting cross-section methods, high equipment requirements, and long measurement cycles, and can solve the problem of difficult torque detection and repeatability. Good, shorten the measurement cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

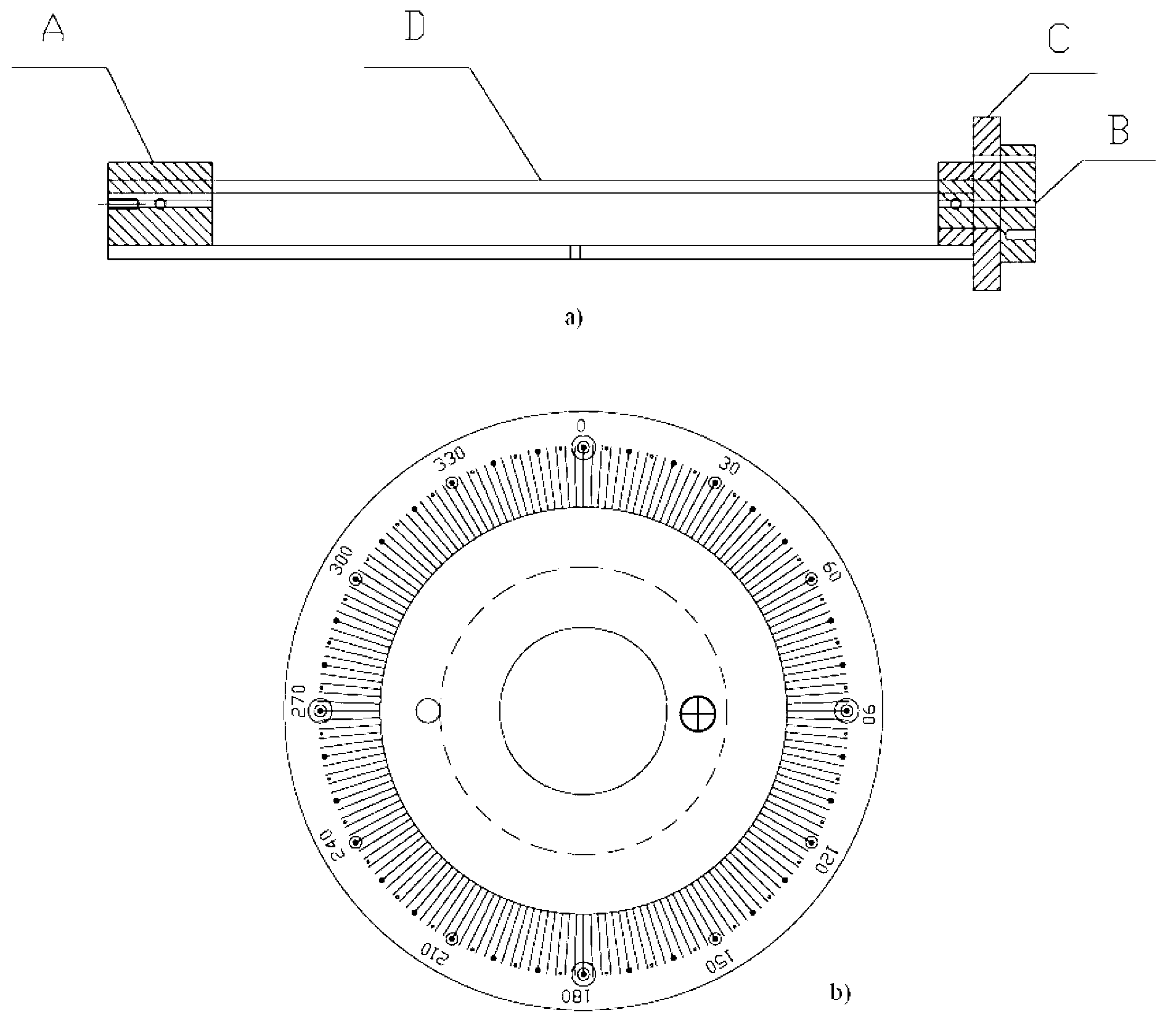

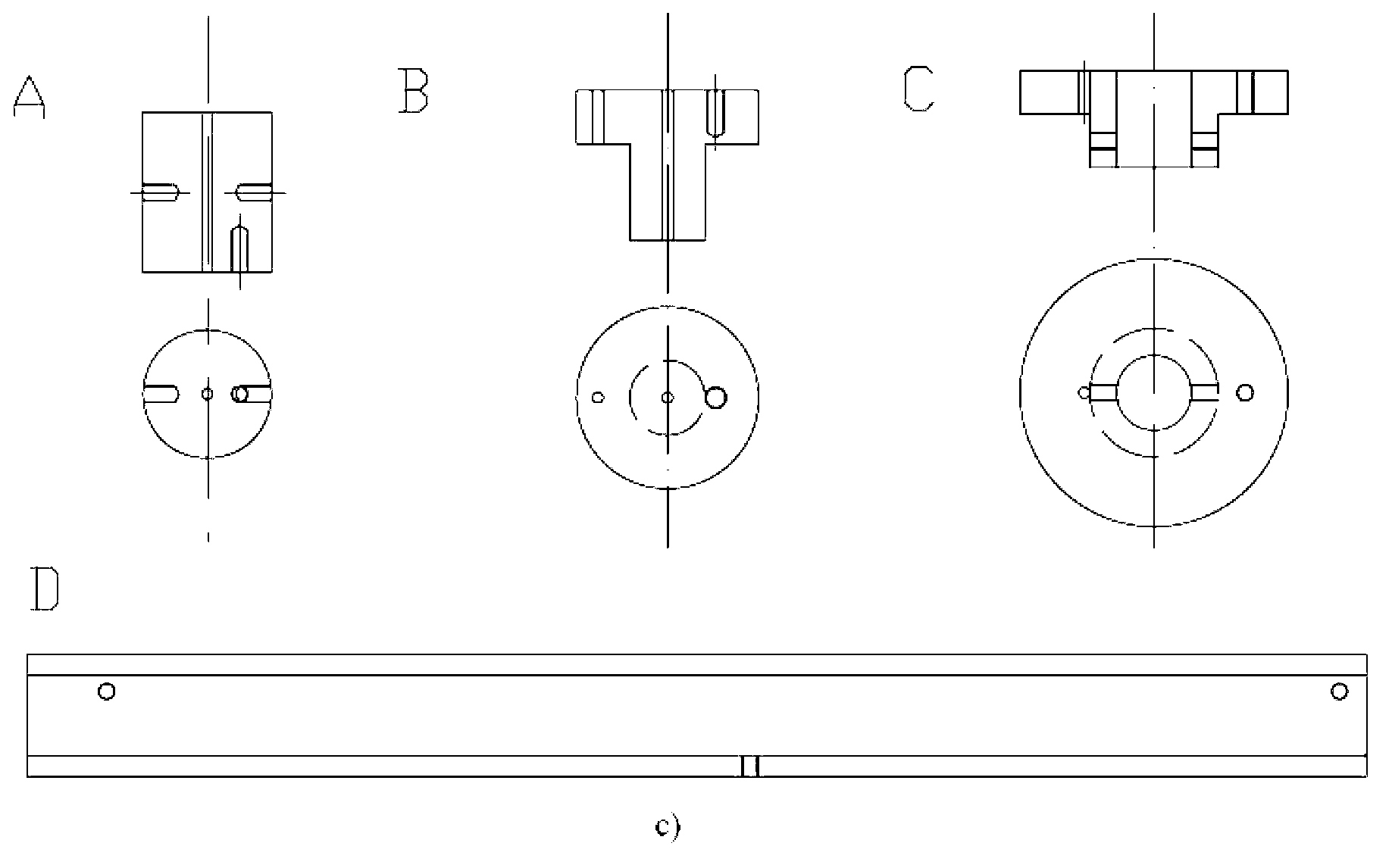

[0057] Example 1: Torque measurement of NbTi / Cu superconducting composite wire for ITER

[0058] See Parts II and III.

example 2

[0059] Example 2: Internal tin method Nb for ITER 3 Sn wire torque measurement

[0060] Internal tin method Nb for ITER 3 Sn wire, the wire diameter is 0.821mm, the core wire diameter is about 6μm, 3000 cores, and the design torque is between 16.1mm and 16.5mm.

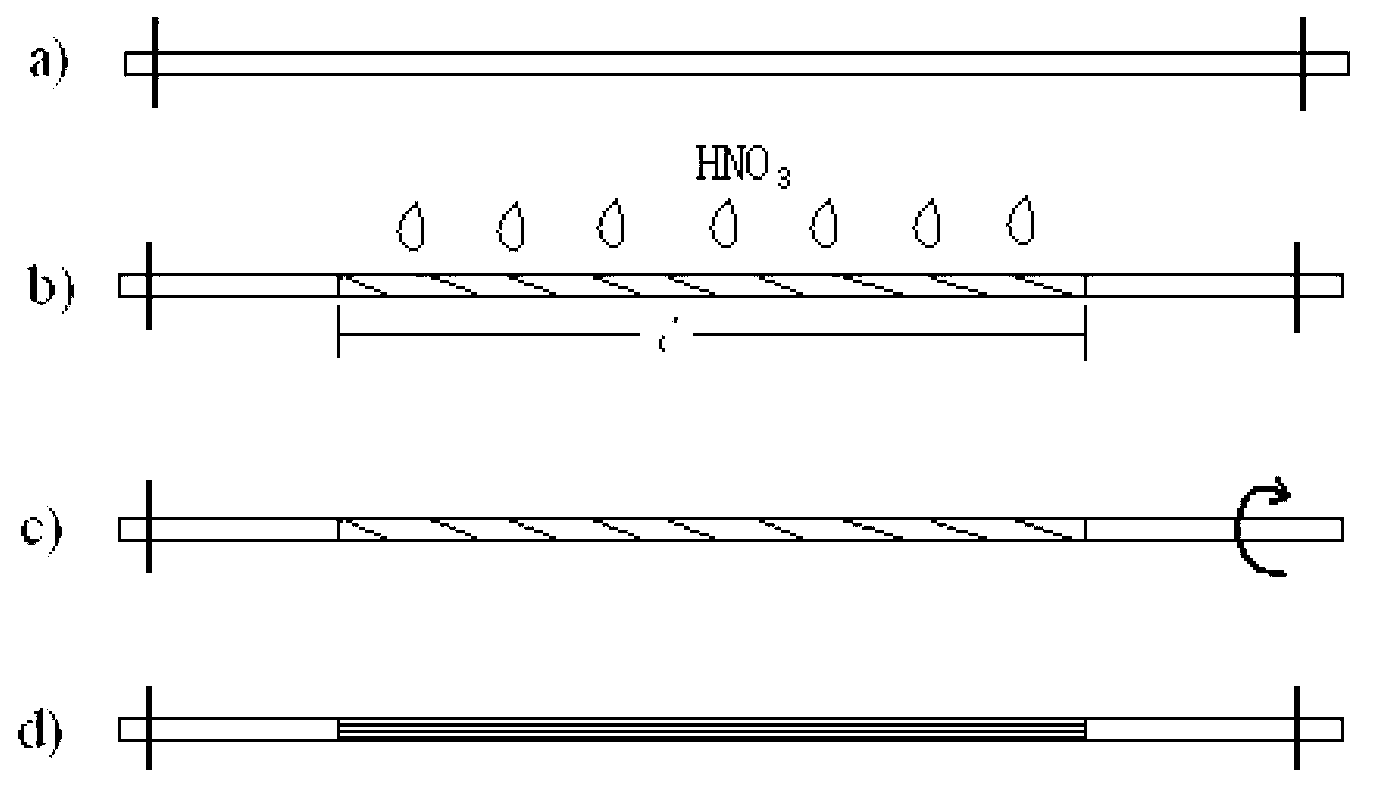

[0061] Compared with NbTi / Cu composite wire, internal tin method Nb 3 Sn wire has a Nb barrier layer on the outside of the core wire. When the outer copper stable layer is corroded, this barrier layer prevents nitric acid from continuing to corrode the internal copper. Therefore, the measurement of the internal tin method Nb 3 The steps of Sn wire torque will be slightly different, as follows:

[0062] Step 1: Preparation before measurement

[0063] Corrosion of the outer copper layer of the sample: Take a section of the sample and put it into 60% nitric acid solution for corrosion. After 15 minutes, the surface copper layer is completely dissolved ( Figure 5 a). The samples were taken out and rinsed with runn...

example 3

[0073] Example 3: Webbing torque measurement for MRI

[0074] Flat tape for MRI is a kind of NbTi / Cu superconducting composite wire. Its operation steps are the same as NbTi / Cu superconducting composite wire for ITER. The measured sample size is: 1.20mm×0.75mm, the design torque is 45mm, the diameter of the core wire is 25μm, and the core wire is 630 cores.

[0075] The measured data are as follows

[0076] l=158.4mm, rotated 3 times, the dial reading is 182°, the total degree is 1262°, the calculated torque L p =45.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com