Feed quantity measuring method and feed quantity monitoring device for combine harvester

A technology for combine harvesters and measuring devices, which is applied to measuring devices, harvesters, weighing, etc., can solve problems such as the inability to realize real-time monitoring of the harvesting and feeding amount of combine harvesters, and achieve simple and easy detection methods. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

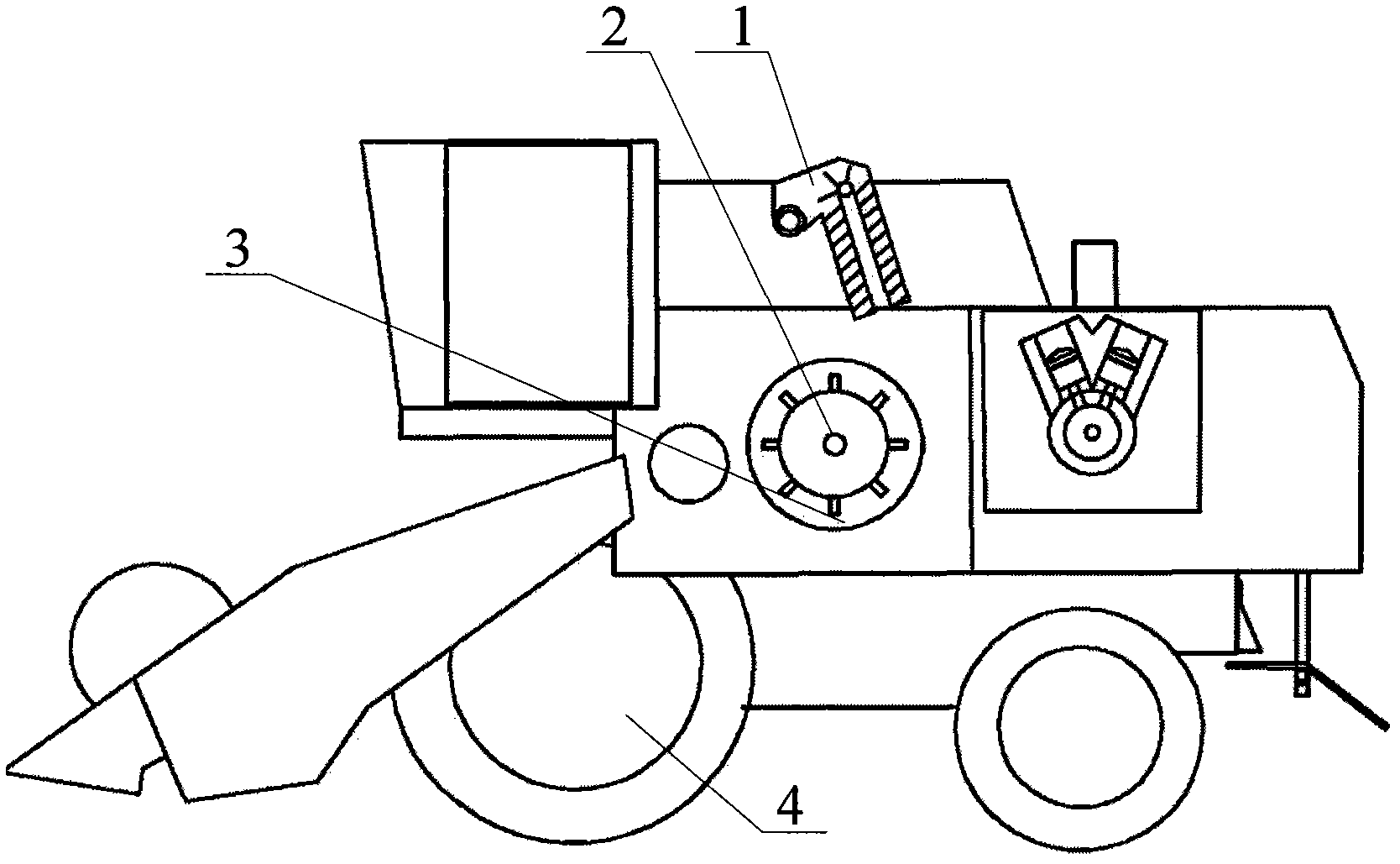

[0069] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

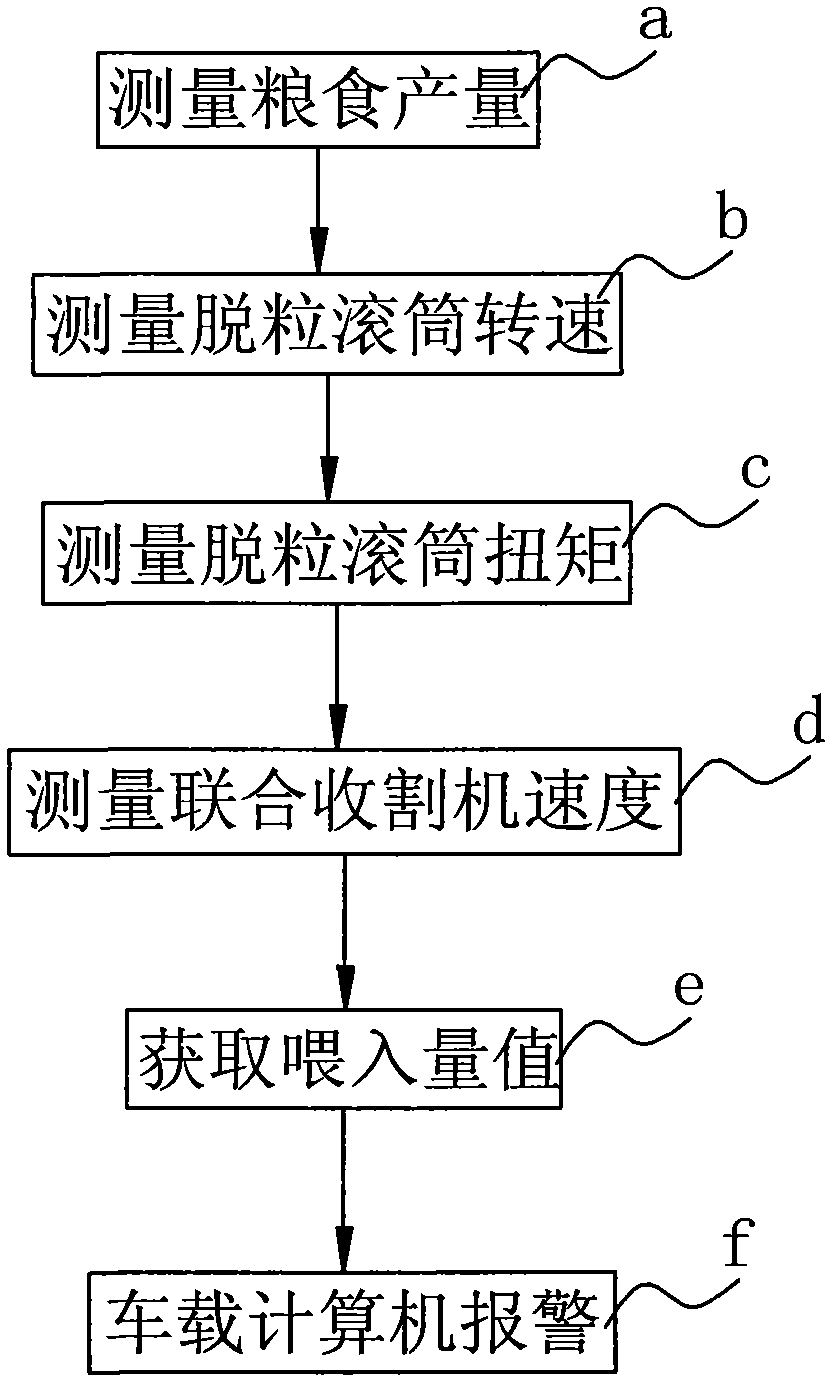

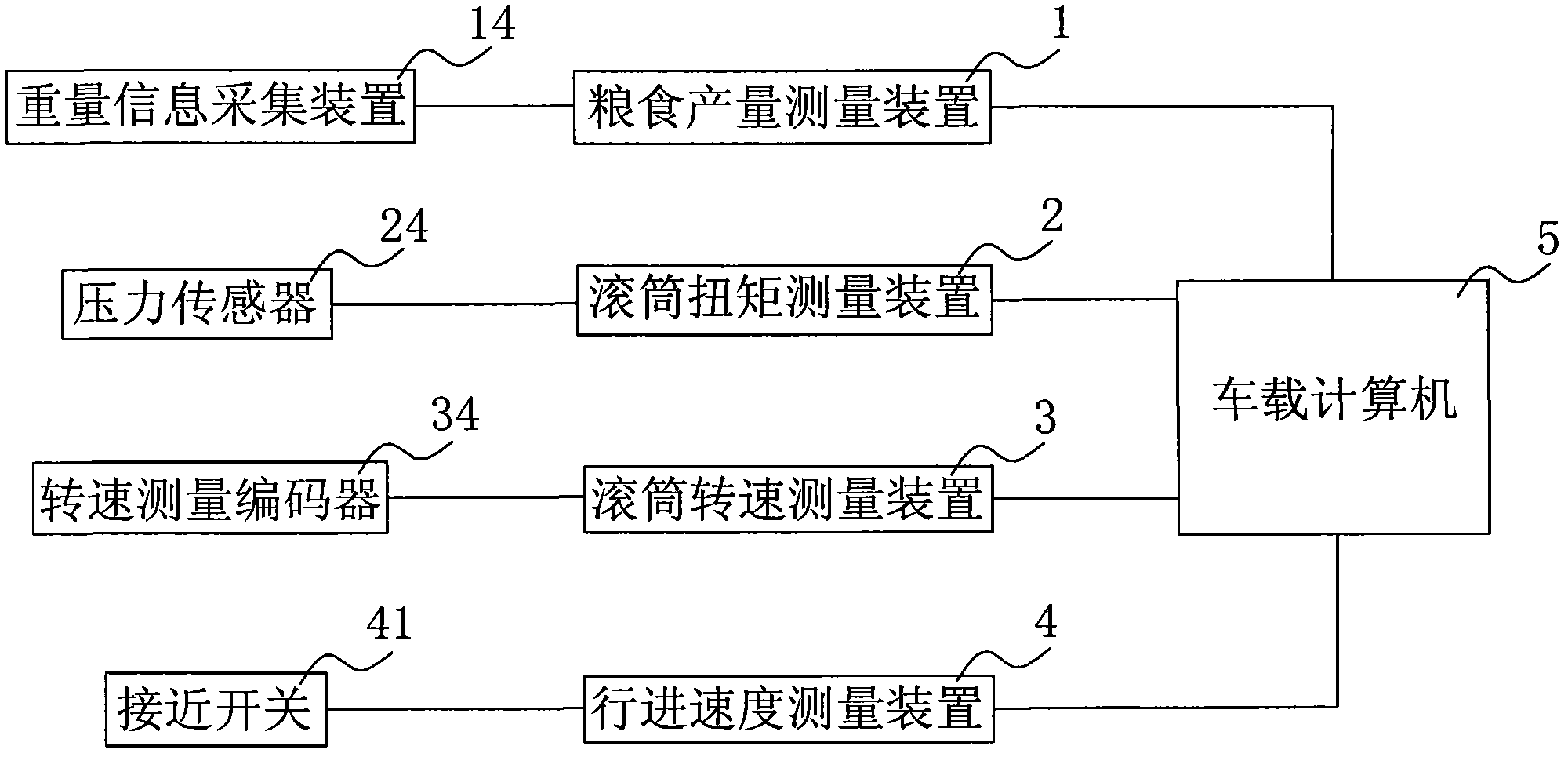

[0070] see figure 1 , figure 1 It is a flow chart of the feed measurement method of the present invention. The method for measuring the feeding amount of a combine harvester of the present invention is used for real-time monitoring of the harvesting feeding amount of a combine harvester, comprising:

[0071] a, the step of measuring the grain output, for obtaining the weight information of the grain in real time by the grain output measuring device 1 arranged on the combine harvester, and sending the weight information into the on-board computer 5 through the on-board signal processing circuit 6;

[0072] b. The step of measuring the rotational speed of the shedding drum, which is used to obtain the rotational speed information of the threshing drum in real time through the rotational speed measuring device 3 of the detached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com