Purifier for adsorbing arsenic hydride and hydrogen phosphide in olefin tail gas and preparation method thereof

A purifying agent, arsine technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., to achieve the effects of low use cost, easy acquisition and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

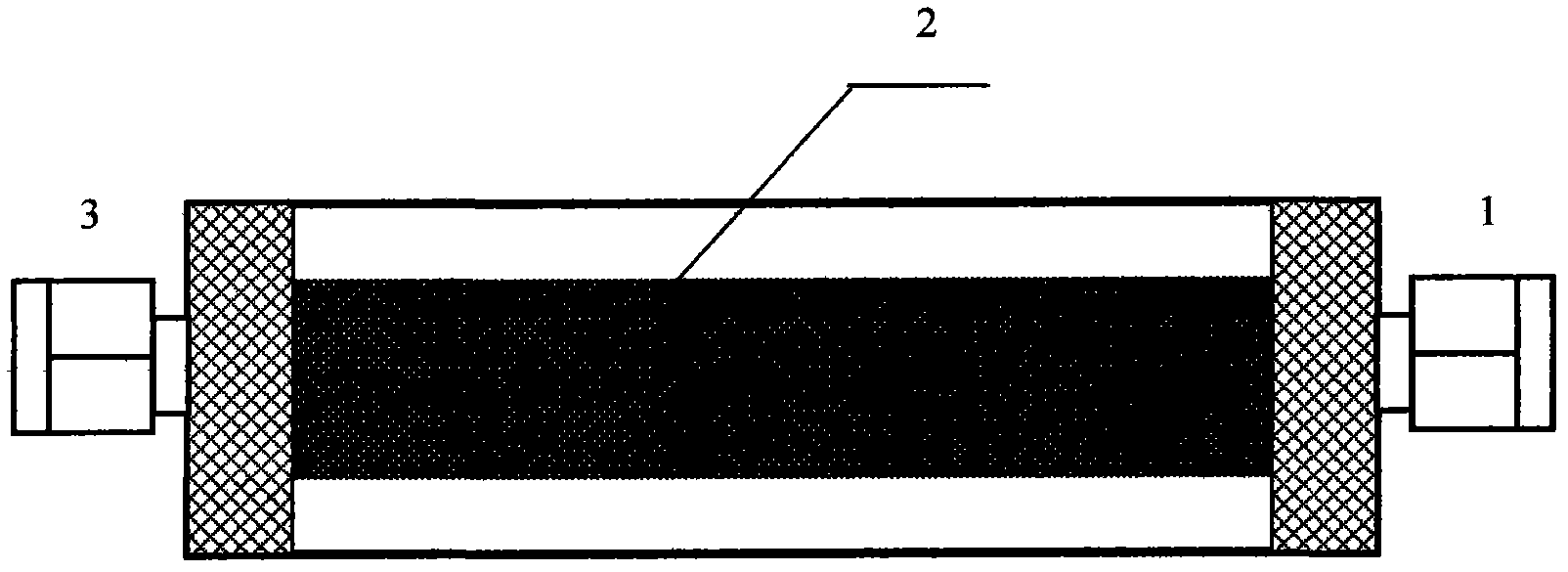

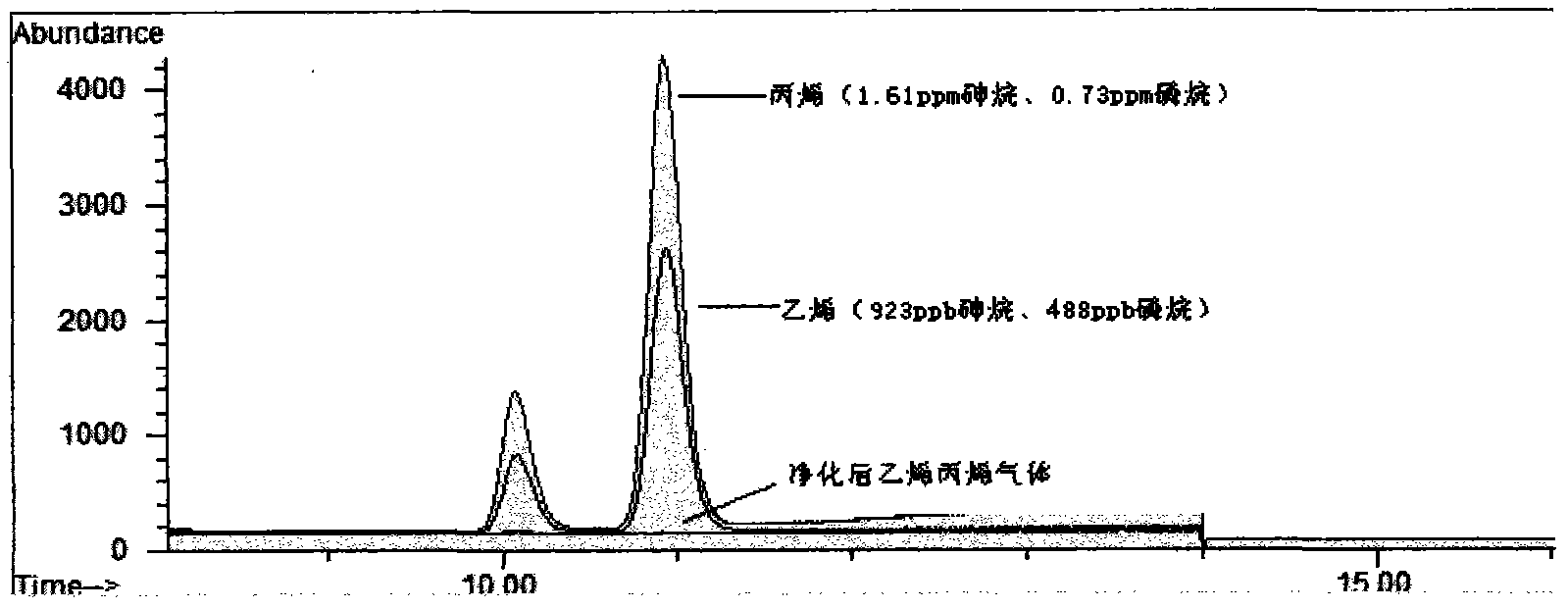

[0024] Weigh 4g of potassium permanganate, 20g of copper sulfate, 20g of zinc sulfate, and 356 water to prepare a mixed solution, then immerse 100g of activated carbon particles in the prepared mixed solution, and stir at 80°C for 6 hours. Dry at 180° C. for 4 hours under the condition of nitrogen protection to obtain the finished cleaning agent. Active components: the mass percentage of potassium permanganate is 2.4%, the mass percentage of copper sulfate is 4.9%, the mass percentage of zinc sulfate is 5.0%; the mass percentage of carrier activated carbon is 87.7%. figure 1 Be 25mm in the pipe of long 200mm for cleaning agent (2) is packed into, and pipe two ends (1), (3) are airtight screw connection. Cracked ethylene gas containing 923ppb (volume fraction) arsine and 788ppb (volume fraction) phosphine is passed into the purification tube filled with purification agent at 100mL / min. GC-MS monitoring spectrum after continuous purification for 10 hours figure 2 , indicating...

Embodiment 2

[0026] Weigh 2g of potassium permanganate, 28g of copper sulfate, 24g of zinc sulfate, and 346 water to prepare a mixed solution, then immerse 100g of activated carbon particles into the prepared mixed solution, and stir at 90°C for 6 hours. Dry at 180° C. for 4 hours under the condition of nitrogen protection to obtain the finished cleaning agent. Active components: the mass percentage of potassium permanganate is 2.0%, the mass percentage of copper sulfate is 5.7%, the mass percentage of zinc sulfate is 5.2%; the mass percentage of carrier activated carbon is 87.1%. figure 1 Be 25mm in the pipe of long 200mm for cleaning agent (2) is packed into, and pipe two ends (1), (3) are airtight screw connection. Cracked ethylene gas containing 923ppb (volume fraction) arsine and 788ppb (volume fraction) phosphine is passed into the purification tube filled with purification agent at 100mL / min. GC-MS monitoring spectrum after continuous purification for 10 hours figure 2 , indicati...

Embodiment 3

[0028] Weigh 4g of potassium permanganate, 6g of copper nitrate, 8g of zinc nitrate, and 182g of water to prepare a mixed solution). Then 100 g of activated carbon particles were immersed in the prepared mixed solution, and stirred at 80° C. for 6 hours. Dry at 180° C. for 4 hours under the condition of nitrogen protection to obtain the finished cleaning agent. Active component: the mass percentage of potassium permanganate is 2.9%, the mass percentage of copper nitrate is 4.3%, the mass percentage of zinc nitrate is 4.8%; the mass percentage of carrier activated carbon is 88%. figure 1 Be 25mm in the pipe of long 200mm for cleaning agent (2) is packed into, and pipe two ends (1), (3) are airtight screw connection. Refinery propylene gas containing 1.61ppm (volume fraction) arsine and 632ppb (volume fraction) phosphine is passed into the purification pipe with purifying agent at 120mL / min. GC-MS monitoring spectrum after continuous purification for 10 hours figure 2 , indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com