Method for preparing silicon dioxide aerogel

A silica and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of impure products, waste of water resources, wide particle size distribution, etc., to avoid washing steps and save water. resources, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041](1) Preparation of silica sol:

[0042] Weigh the powder containing silicon dioxide (particle size 0.1-0.4 μm, mass percentage greater than 85%) and the powder containing calcium oxide according to the molar ratio of 1:0.8-1:1.2, after thorough grinding and mixing, Calcined at a temperature of ℃, and reacted for 15-100min to obtain the product;

[0043] Put the obtained sintered product into a sulfuric acid solution with a concentration of 3%-10%, fully stir and mix, react at room temperature-80°C for 20-80min, and adjust the pH value at 4 by adding sulfuric acid or sintered material -7, cooling the reacted mixed solution and suction filtering to remove the precipitate to obtain a silica sol;

[0044] (2) Preparation of silica gel:

[0045] Place the silica sol obtained in (1) at room temperature -50°C for 2-24 hours to form a gel state, and continue to place and age for 2-30 hours to obtain a silica gel;

[0046] (3) Solvent replacement:

[0047] The gel obtained ab...

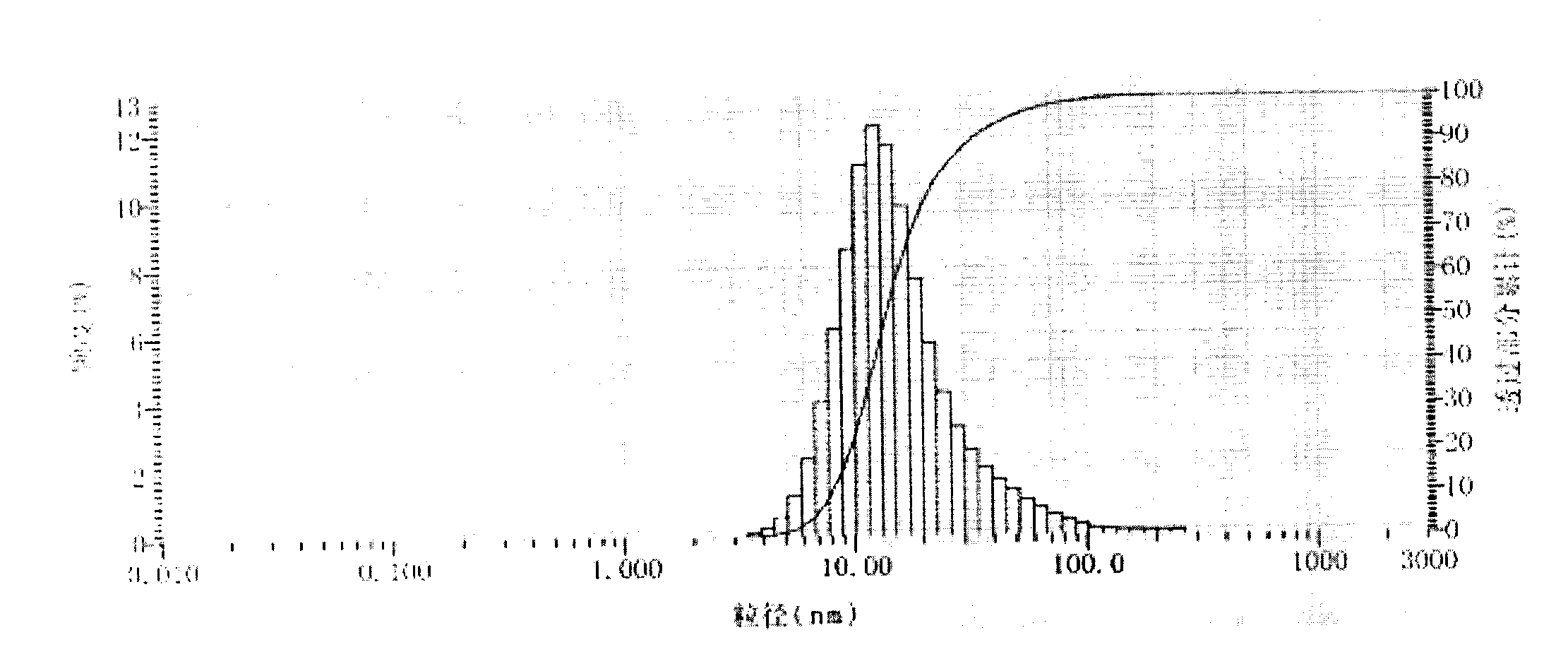

Embodiment 1

[0054] (1) Preparation of silica sol: take microsilica powder 1000g (density is 150Kg / m 3 , the average particle size is 0.18μm), quicklime 900g, of which SiO 2 The molar ratio of CaO and CaO is 1:0.95. Put the two into the disperser, fully grind and mix for 10 minutes, then transfer the mixed material into a high-temperature reaction furnace, maintain the reaction temperature at 850±10°C, and keep stirring for 40 minutes to obtain sintering product;

[0055] Cool the obtained sintered product to a temperature of 50°C, then transfer all of it to a reaction kettle, inject 3200 mL of sulfuric acid solution with a concentration of 5% (mass concentration), and stir continuously at room temperature to allow it to fully react. After about 50 minutes, the sintered product Dissolve completely, and new precipitates appear continuously, add the sulfuric acid solution or the sintered product to adjust the pH of the reaction solution to 4, filter the mixed solution after the reaction, fi...

Embodiment 2

[0061] (1) Preparation of silica sol: take 1000g of microsilica fume (average particle size is 0.18μm), 950g of quicklime, of which SiO 2 The molar ratio to CaO is 1:1.01. Put the two into the disperser, fully grind and mix for 10 minutes, then transfer the mixed material into a high-temperature reaction furnace, maintain the reaction temperature at 800°C, and keep stirring for 50 minutes to obtain a sintered product;

[0062] Cool the obtained sintered product to a temperature of 50°C, then transfer all of it into a reaction kettle, inject 2000mL of sulfuric acid solution with a concentration of 8% (mass concentration), stir continuously at 40°C to make it fully react, and after about 30min, sinter The product is completely dissolved, and new precipitates appear constantly. Add the sulfuric acid solution or the sintered product to adjust the pH of the reaction solution to 4.5, filter the reaction mixed solution with suction, filter the precipitate, collect the filtrate, and ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com