Method for preparing rare earth permanent magnetic material

A technology of rare earth permanent magnets and permanent magnets, which is applied in the fields of magnetic materials, inductors/transformers/magnets manufacturing, electrolytic coatings, etc. It can solve the problems of waste of heavy rare earth metals, increase the price of magnets, increase the number of processes, etc., and reduce the amount of heavy rare earths , the cost-effective advantage of the product, and the effect of improving the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

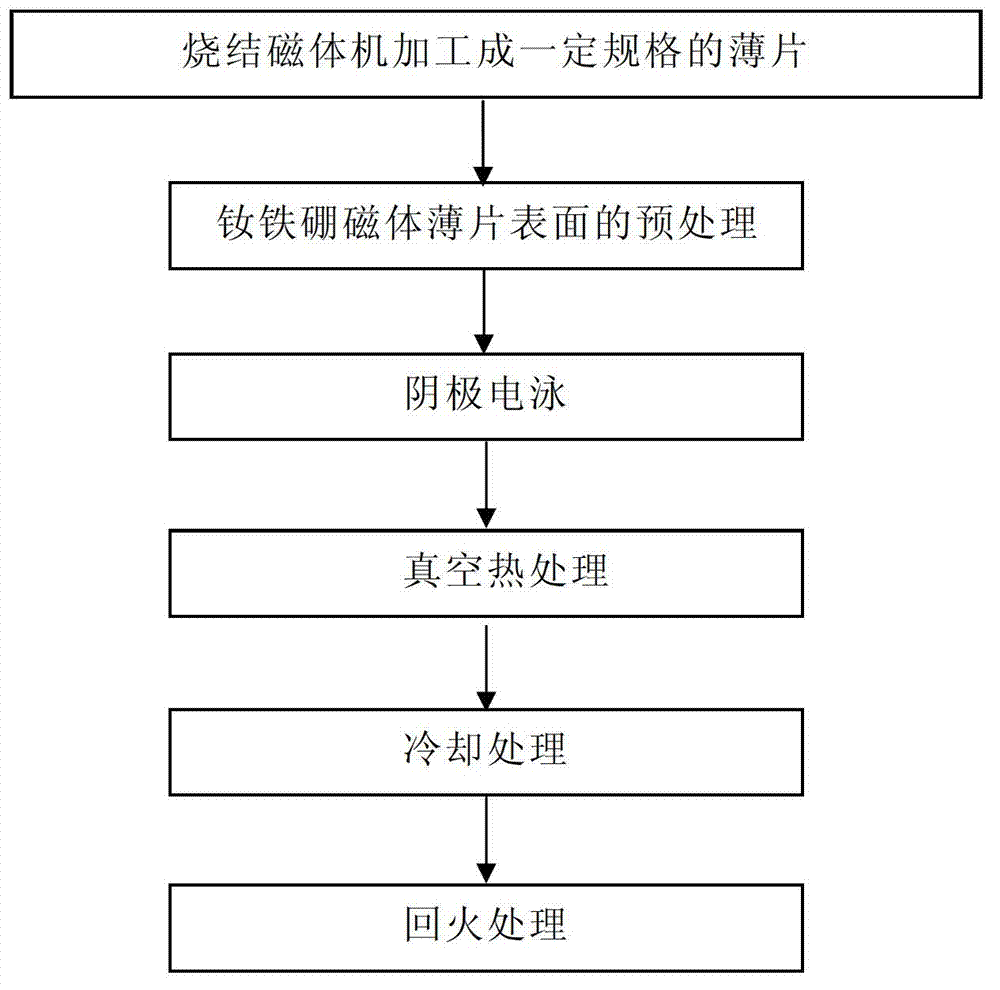

Method used

Image

Examples

preparation example Construction

[0031] The above-mentioned LRHs can be obtained by the following preparation method: slowly drop the mixed alkali solution into the vigorously stirred rare earth metal cation solution, the speed of the vigorously stirred is 500~1500r / min, when the pH value of the system reaches 6.7-6.9 , stop adding the mixed alkali solution dropwise, and then mechanically stir the slurry at room temperature for 30 minutes to crystallize the slurry at 100-120°C for 24-48 hours, then filter, wash and dry to obtain LRHs powder, wherein the mixed The alkali solution is an aqueous solution with a concentration of sodium hydroxide of 0.1-0.4 mol / L and a concentration of soluble sodium salt of 0.1-0.3 mol / L, and the total concentration of rare-earth metal cations in the rare-earth metal cation solution is 0.1-0.4 mol / L , can be one or more rare earth metal cations, and the rare earth metal cation solution or the mixed alkali solution contains X, that is, the interlayer anion.

[0032] The NdFeB perm...

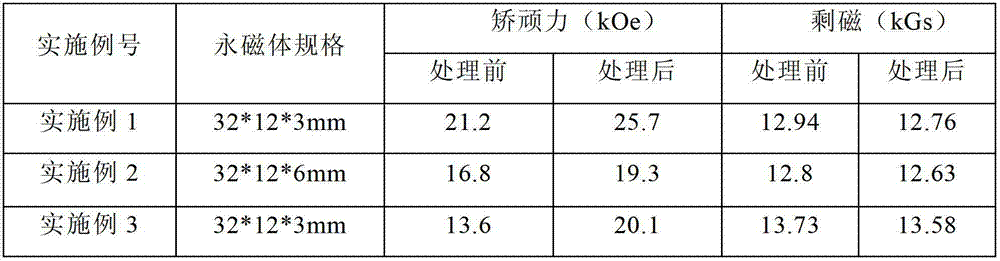

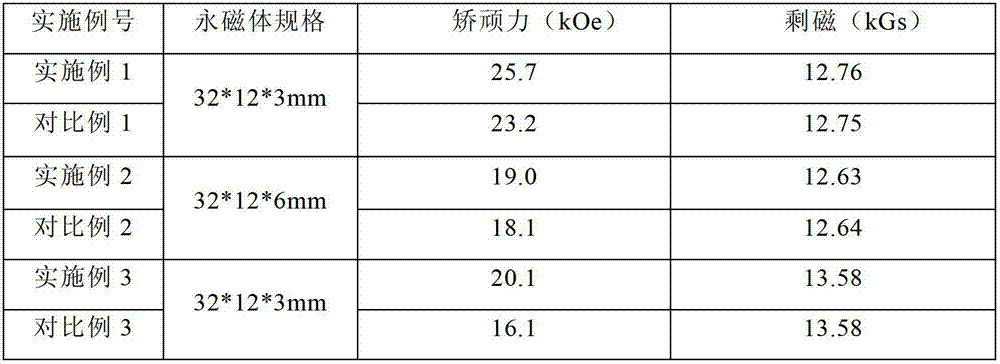

Embodiment 1

[0041] (1) Prepare Tb(NO at a concentration of 0.1mol / L 3 ) 3 Aqueous solution, placed in a four-necked bottle; weigh solid NaOH and solid NaNO respectively 3 , and then add water to make NaOH concentration 0.1mol / L, NaNO 3 Concentration is the mixed alkali solution of 0.1mol / L; The above-mentioned mixed alkali solution is slowly added dropwise to the above-mentioned Tb(NO 3 ) 3 In the solution, when the pH value of the system reaches 6.80, stop adding the mixed alkali solution dropwise, move the slurry to the reaction kettle after mechanical stirring at room temperature for 30 minutes, crystallize at 120°C for 24 hours, filter, wash, and dry to obtain a layered Rare earth hydroxide (Tb) 2 (OH) 5 NO 3 ·nH 2 O powder (n=2~5);

[0042] (2) The sintered NdFeB magnet is processed into thin slices with the specifications shown in Table 1, soaked in a degreasing tank for 10 minutes to remove the oil on the surface of the magnet, and then wash the surface with water and then ...

Embodiment 2

[0046] (1) Prepare a Dy(NO3)3 solution with a concentration of 0.2mol / L and place it in a four-necked bottle; prepare 0.15mol / L NaOH and 0.2mol / L NaNO 3 The mixed alkali solution; the mixed alkali solution was slowly added dropwise to the vigorously stirred Dy(NO3) solution, and when the pH value of the system reached 6.85, the dropwise addition of the mixed alkali solution was stopped, and the slurry was transferred after 30 minutes of mechanical stirring at room temperature. into the reaction kettle, crystallized at 120°C for 24h, filtered, washed, and dried to obtain layered rare earth hydroxide (Dy) 2 (OH) 5 NO 3 ·nH 2 O powder (n=2~5);

[0047] (2) The sintered NdFeB magnet is processed into thin slices with the specifications shown in Table 1, soaked in a degreasing tank for 10 minutes to remove the oil on the surface of the magnet, and then wash the surface with water and then use dilute HNO 3 Pickling for about 40s, then washing with water, ultrasonic treatment for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com