Composite structure plate of recombination bamboo wood and medium-density fiberboard and manufacture method thereof

A technology for recombining bamboo and composite structures, which is applied in the direction of manufacturing tools, joining of wooden veneers, wood processing appliances, etc., can solve the problem of low raw material utilization rate and poor quality controllability of wood rotary cut veneer and bamboo curtain and bamboo mat High, complex processing technology and other issues, to achieve excellent anti-ultraviolet performance, expand the scope and field of use, and achieve the effect of uniform material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

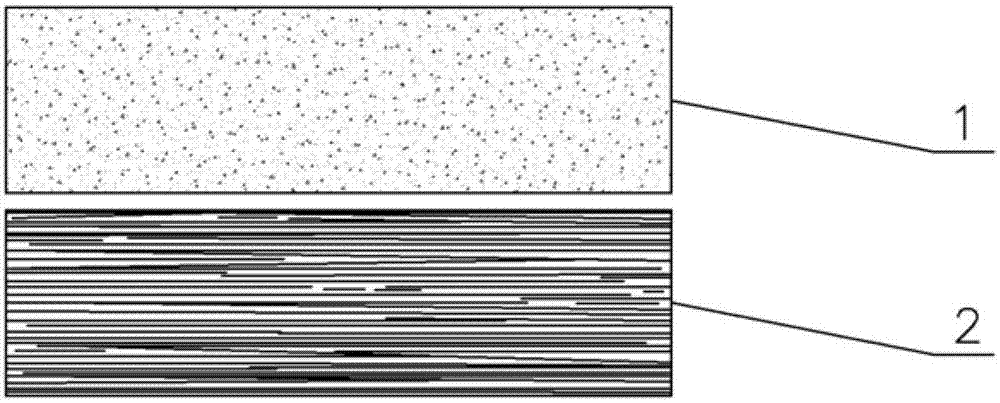

[0039] The present embodiment provides a kind of recombined bamboo and medium-density fiberboard composite structure board, and it can be used for making doors and windows (such as double-layer structure doors and windows) etc., structure such as figure 1 shown. The boards used in the composite structure board are medium density fiberboard 1 produced from wood fiber (single tree species or mixed tree species with similar properties) and recombined bamboo material 2 obtained by dipping and molding bamboo tow (Moso bamboo or Ci bamboo).

[0040] The structure of the composite structural board provided in this embodiment is based on recombined bamboo 2, and the upper layer is glued with a medium density fiberboard 1 coated with isocyanate glue on one side, which is manufactured according to the following steps:

[0041] Material selection: use 20mm, 25mm thick medium density fiberboard with a density of 0.75g / cm 3 , the water content is 8%; the selected density is 1.05g / cm 3 , ...

Embodiment 2

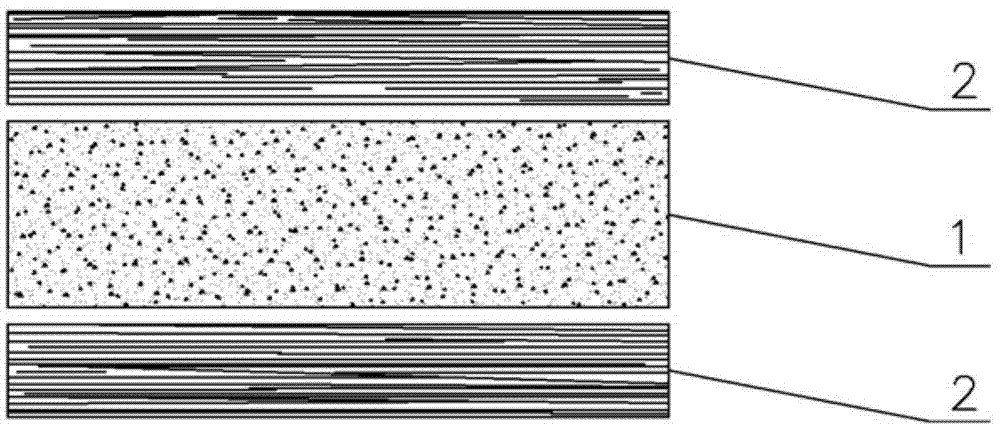

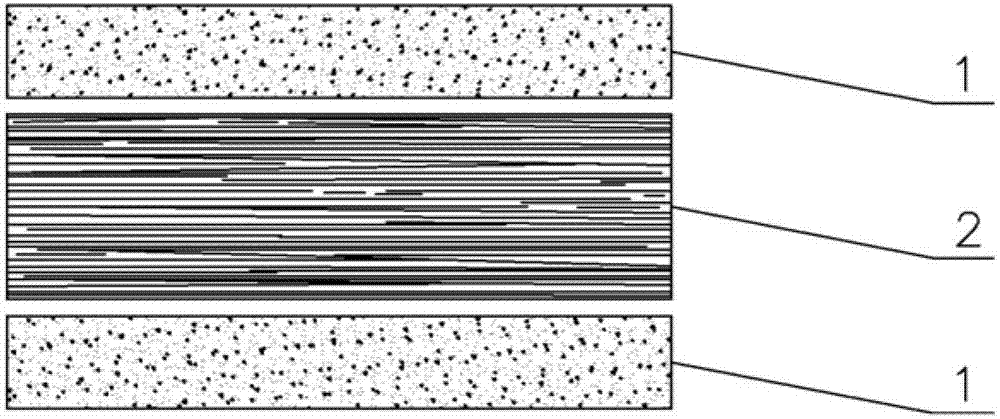

[0054] This embodiment provides a composite structure board of recombined bamboo and medium density fiberboard, which can be used to manufacture floors, with a structure such as figure 2 shown. The boards used in the composite structure board are medium density fiberboard 1 produced from wood fiber (single tree species or mixed tree species with similar properties) and recombined bamboo material 2 obtained by dipping and molding bamboo tow (Moso bamboo or Ci bamboo).

[0055] The structure of the composite structure board provided by this embodiment is a medium density fiberboard 1 coated with isocyanate glue on both sides as the core layer, and a layer of recombined bamboo 2 coated with isocyanate glue on one side is glued to the top and bottom of it. It is manufactured according to the following steps of:

[0056] Material selection: use 9mm thick medium density fiberboard with a density of 0.75g / cm 3 , the water content is 8%; the selected density is 1.05g / cm 3 , Recomb...

Embodiment 3

[0066] This embodiment provides a composite structural board of recombined bamboo and medium density fiberboard, which can be used to manufacture building templates, with a structure such as figure 2 shown. The boards used in the composite structure board are medium density fiberboard 1 produced from wood fiber (single tree species or mixed tree species with similar properties) and recombined bamboo material 2 obtained by dipping and molding bamboo tow (Moso bamboo or Ci bamboo).

[0067] The structure of the composite structure board provided by this embodiment is a medium density fiberboard 1 coated with isocyanate glue on both sides as the core layer, and a layer of recombined bamboo 2 coated with isocyanate glue on one side is glued to the top and bottom of it. It is manufactured according to the following steps of:

[0068] Material selection: use 10mm thick medium density fiberboard with a density of 0.75g / cm 3 , the water content is 8%; the selected density is 1.05g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com