Submersed nozzle for high-casting-speed continuous casting crystallizer

A continuous casting crystallizer and immersion technology, which is applied in the field of continuous casting of steel, can solve the problems of reducing the impact kinetic energy of molten steel due to friction, poor stability of streams flowing out of side holes, and unfavorable uniformity of billet shell growth, etc., so as to avoid The effects of excessive liquid level fluctuations and slag appearance, improving internal quality, reducing impact and interference to the liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

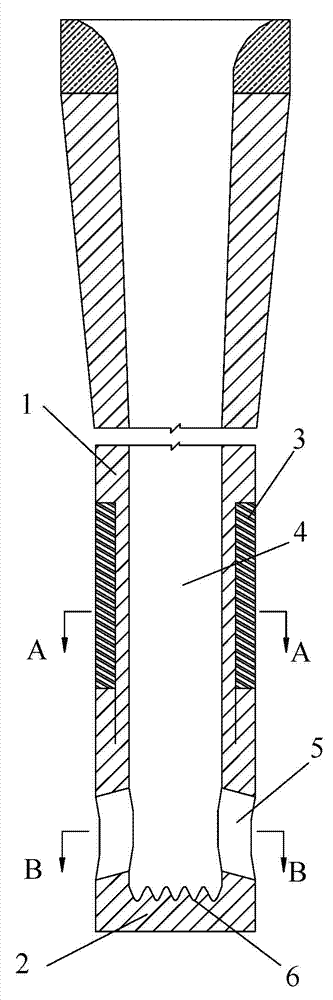

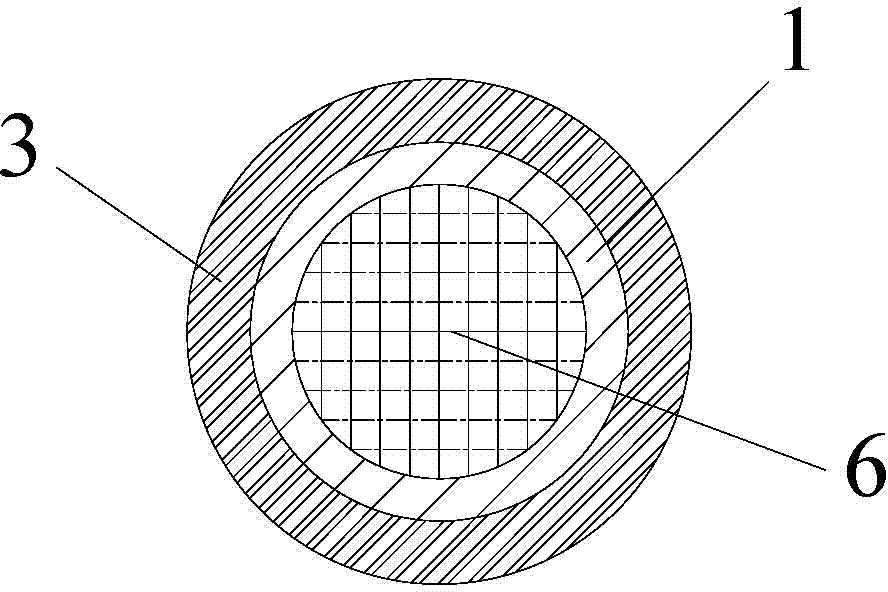

[0030] When pouring a slab with a casting speed of 1.5m / min, such as figure 1 and figure 2In the embodiment of the double-sided holes shown, the cross-sections of the side wall 1 and the inner cavity 4 are both circular during casting. Two side holes 5 of the same size and shape are arranged on the side wall 1 at 20 mm above the upper surface of the bottom cover 2. The holes 5 on both sides are axially symmetrical along the center line of the inner cavity 4 of the nozzle, and the center line of the side holes 5 is in the shape of - The inclination angle of 15°; the upper surface of the back cover 2 is provided with criss-cross wave-shaped grooves 6, the width of the wave-shaped grooves 6 is 5 mm, the depth from the trough to the bottom of the side wall cavity is 6 mm, and the wave crest into the side wall The height of the bottom of the chamber is 2mm, and the distance between adjacent columns and rows is 6mm. The side hole 5 is surrounded by a wavy curved surface 7, and the...

Embodiment 2

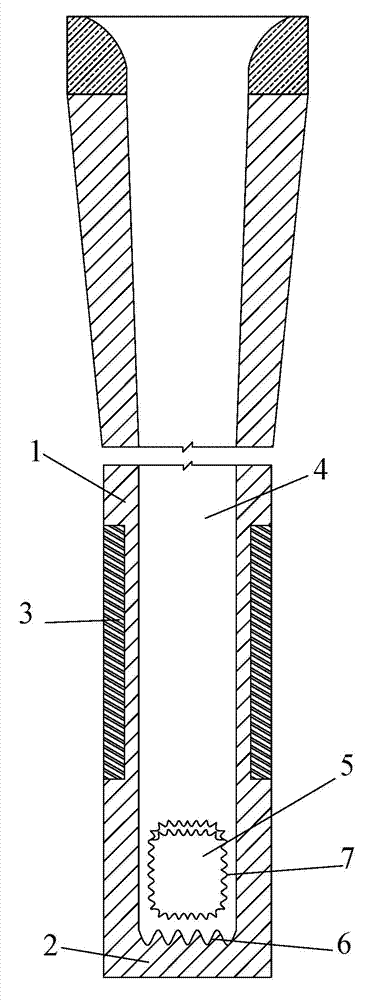

[0032] When the pouring speed is 2m / min bloom, you can use such as Figure 6 The shown embodiment with four side holes is poured, and the cross-section of the side wall 1 and the inner cavity 3 is set to be circular. Four side holes 5 of the same size and shape are arranged on the side wall 1 at 20 mm above the upper surface of the bottom cover 2 of the submerged nozzle. The center line is axisymmetric, and the center line of the side hole 5 is at an inclination angle of -15° to the horizontal plane; the upper surface of the back cover 2 is provided with crisscross wavy grooves 6, the width of the wavy grooves 6 is 6mm, and the trough reaches The depth of the bottom of the side wall cavity is 5 mm, the height from the crest to the bottom of the side wall cavity is 1 mm, and the distance between adjacent columns and rows is 6 mm; the side hole 5 is surrounded by a wavy surface 7, and the wavy surface The height difference between the trough and the crest of 7 is 6 mm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com