Temperature-resistant thermal-spray radar absorbing coating and preparation method of spraying powder thereof

A technology of wave absorbing coating and spraying powder, applied in the direction of coating, metal material coating process, melting spray plating, etc., can solve the problem of low temperature resistance of wave absorbing coating, and achieve good wave absorbing performance and mechanical performance. Excellent effect with simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Further, the preparation method of the above-mentioned radar absorbing coating powder of the present invention, comprising the following steps:

[0040] Step 1: Mix the glass, glaze or enamel binder with the absorbent evenly, add the organic binder, and stir well to form a slurry, so that the absorbent in the slurry is evenly dispersed;

[0041] Step 2: Vacuum dry the slurry obtained in step 1 to obtain a green body with low strength, and prepare thermal spraying powder by smelting crushing or sintering crushing process; powder can also be prepared by agglomeration and sintering process, and spray the slurry Dry and granulate to obtain spherical powder, which can be used for thermal spraying after drying and light sintering.

[0042] Preferably, step 3 may also be included: after the above-mentioned step 2 is completed, the powder is treated by a flame spray gun or a plasma spray gun to form a molten skeleton structure for the glass bond material, and at the same time f...

Embodiment 1

[0052] Example 1: Low melting point glass and nickel-coated SiC absorber system material and coating preparation

[0053] Raw material: PbO 2 -SiO 2 400g of glass (average particle size<2μm), 100g of 30wt.% Ni-coated SiC powder (<14μm).

[0054] After fully mixing the above raw material powders, add pure water and diluted polyvinyl alcohol solution (dilution ratio is about 10:1), stir well, and fully dry the obtained slurry in a vacuum drying oven to form a dry green body , put the green body into a vacuum sintering furnace, control the furnace temperature to 600°C, control the heating rate to 100°C / 15min during the sintering process, and keep it at 600°C for 5 hours at the same time to ensure that the glass material is completely sintered. Crushing, pulverizing, and sieving to obtain thermal spraying powder materials with a particle size ranging from 45 μm to 98 μm. Oxygen-acetylene flame spraying system is used to prepare the coating, and the flame temperature of the flam...

Embodiment 2

[0056] Raw materials: 350g of phosphate glass powder (average particle size <3μm), 150g of FeNiCoAlSiRe alloy (~10μm).

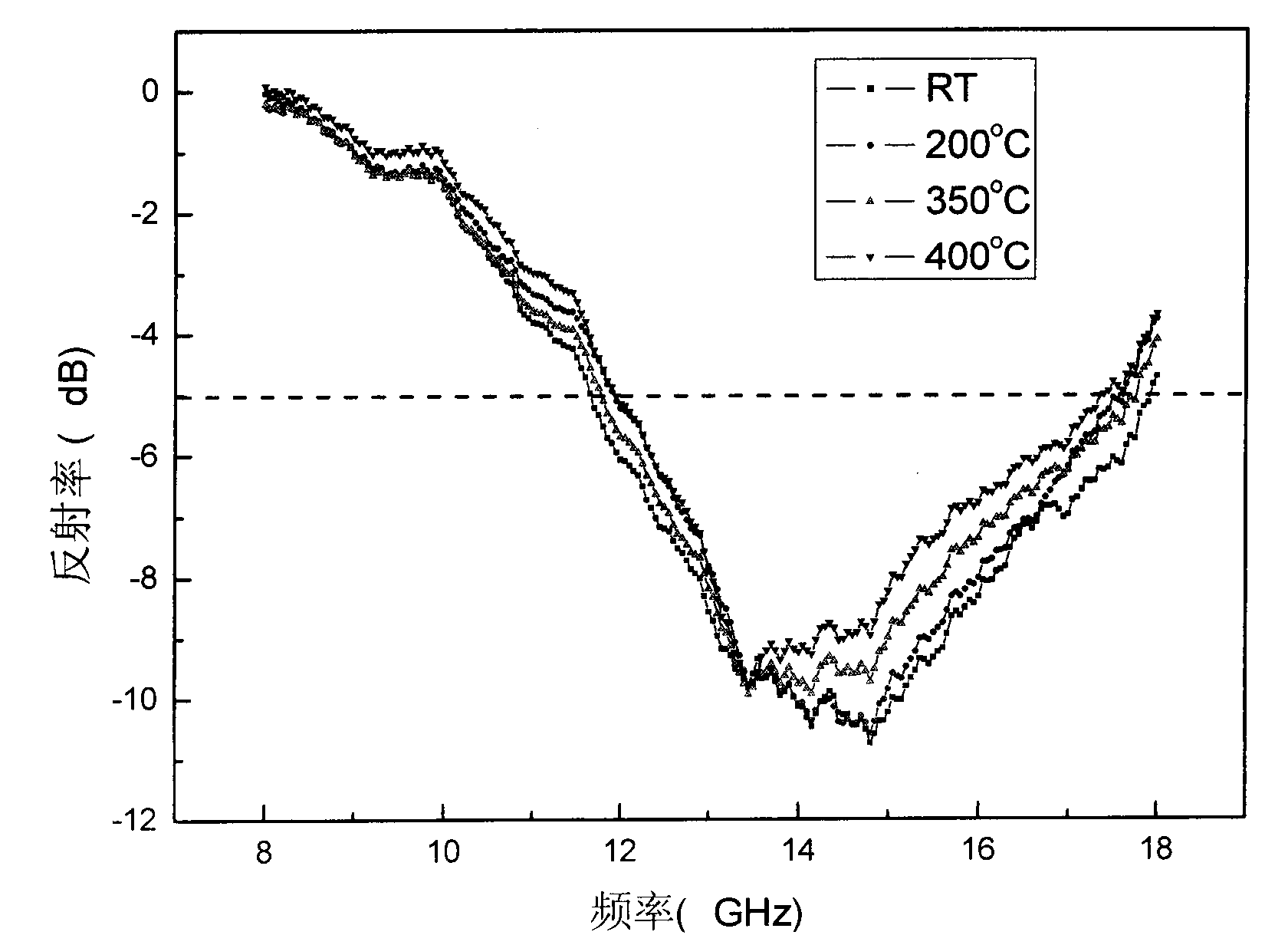

[0057] Fully mix the above raw materials, add a small amount of pure water to ensure that the solid content of the slurry is 50-65%, add 1-1.5% polyvinyl alcohol (PVA) as a binder during the stirring process, and use centrifugal spray drying and granulation equipment to carry out Granulation treatment to obtain spherical powder, the powder is vacuum-dried at low temperature (100-150° C.), and the dried powder is sieved to finally obtain spherical powder with a particle size between 25 μm and 53 μm. The supersonic flame spraying equipment was used for spraying to prepare a coating with a thickness of 1.2mm, and the peak reflectivity of the coating was (9.76GHz, -9.29dB). The bonding strength of the coating is 18MPa, and when the coating thickness is 0.5mm, the surface density is 1.78Kg / m 2 . The frequency-reflectivity curve results of the coating performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com