Modified flame retardant composite resin and metal pipe for mine as well as preparation method of modified flame retardant composite resin and metal pipe

A technology of flame-retardant composite and metal pipes, which is applied in the direction of rigid pipes, pipes, mechanical equipment, etc., and can solve the problems of easy corrosion of the surface of metal pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The modified flame-retardant composite resin for coating the surface of mine metal pipes of the present invention comprises the following components in parts by weight: 80-100 parts of a mixture of polyethylene and polypropylene

[0031] 5-10 parts of terpene resin,

[0032] 5-10 parts of zinc oxide,

[0033] 3-6 parts of ethoxylated alkylamine,

[0034] 2 to 5 parts of paraffin,

[0035] 1-2 parts of trinonylphenyl phosphite.

[0036] In this embodiment, the terpene resin is used as a modifier to improve the fluidity of the coating, and to improve the adhesion, impact toughness, environmental cracking resistance, fatigue resistance and hardness of the steel base; zinc oxide is used as a stabilizer to improve the environmental weather resistance ; Ethoxylated alkylamine is antistatic agent, which improves corrosion resistance and service life; paraffin wax is used as leveling agent, which increases leveling property and smooth surface, forming a flat and smooth film ...

Embodiment 2

[0049] This embodiment provides a method for preparing the modified flame retardant composite resin, comprising the following steps:

[0050] (1) Weigh each component according to the formula and mix for 10-20 minutes;

[0051] (2) Put the mixed material into the granulator for extrusion granulation;

[0052] (3) Sieve and size the granules extruded from the granulator;

[0053] (4) Dry the obtained granules at a temperature of 60-80° C. for 4-6 hours.

[0054] Described formula adopts the formula described in embodiment 1.

[0055] In this embodiment, the terpene resin is used as a modifier to improve the fluidity of the coating, and to improve the adhesion, impact toughness, environmental cracking resistance, fatigue resistance and hardness of the steel base; zinc oxide is used as a stabilizer to improve the environmental weather resistance ; Ethoxylated alkylamine is antistatic agent, which improves corrosion resistance and service life; paraffin wax is used as leveling ...

Embodiment 3

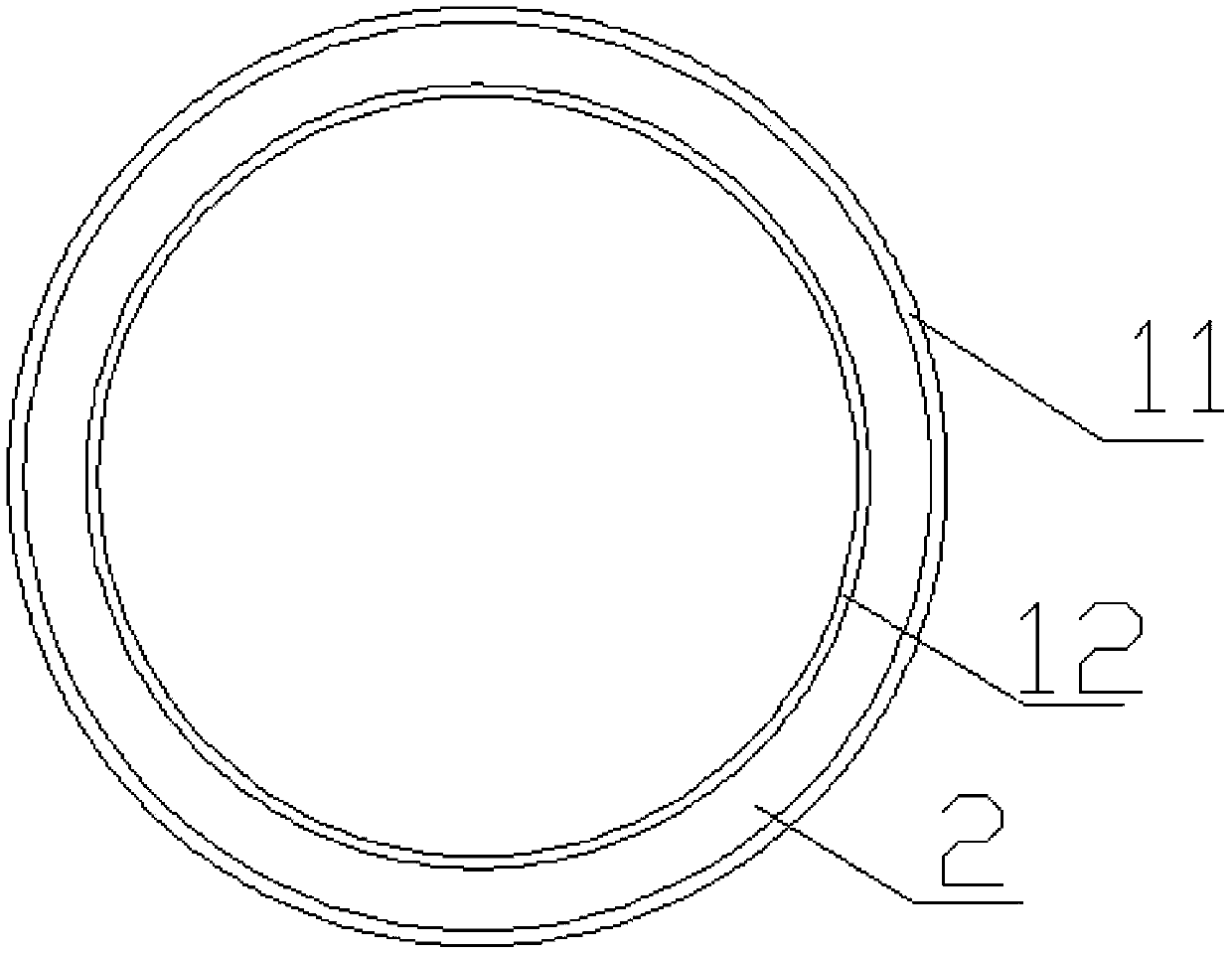

[0057] see figure 1 , the present embodiment provides a metal pipe for mines, including a metal pipe body 2 and a modified flame-retardant composite resin coating coated on the surface of the metal pipe body, the modified flame-retardant composite resin coating includes an inner coating 12 and outer coating 11. The modified flame retardant composite resin coating can be prepared by using the modified flame retardant composite resin described in Example 1 above.

[0058] The thickness of the modified flame-retardant composite resin coating is preferably 0.1-3mm.

[0059] Among the various components involved in the modified flame-retardant composite resin coating coated on the metal pipe body, the terpene resin is used as a modifier to improve the fluidity of the coating and the adhesion to the steel base. Impact toughness, environmental cracking resistance, fatigue resistance and hardness; zinc oxide is a stabilizer to improve environmental weather resistance; ethoxylated al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com