Proximity field exposure device and method

An exposure device and exposure method technology, applied in the field of photolithography, can solve the problems of high cost, cannot replace Aligner, low yield, etc., and achieve the effects of low cost, fast movement speed, and short stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings. For the convenience of describing and highlighting the present invention, relevant components existing in the prior art are omitted from the drawings, and the description of these known components will be omitted.

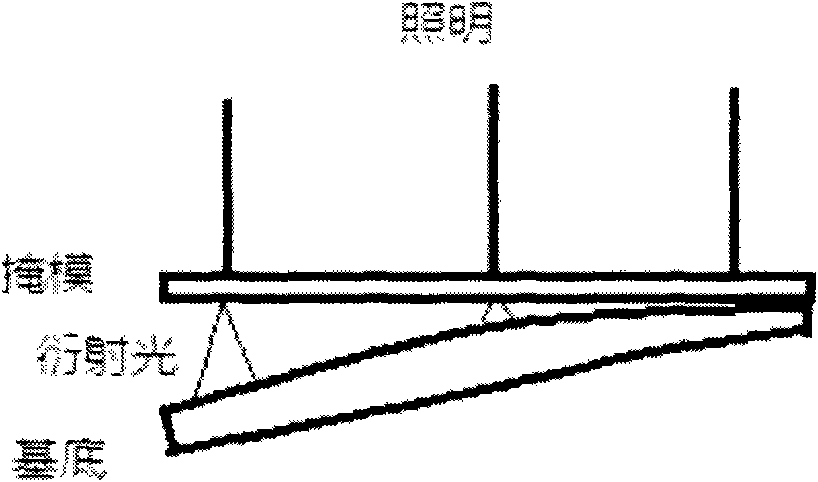

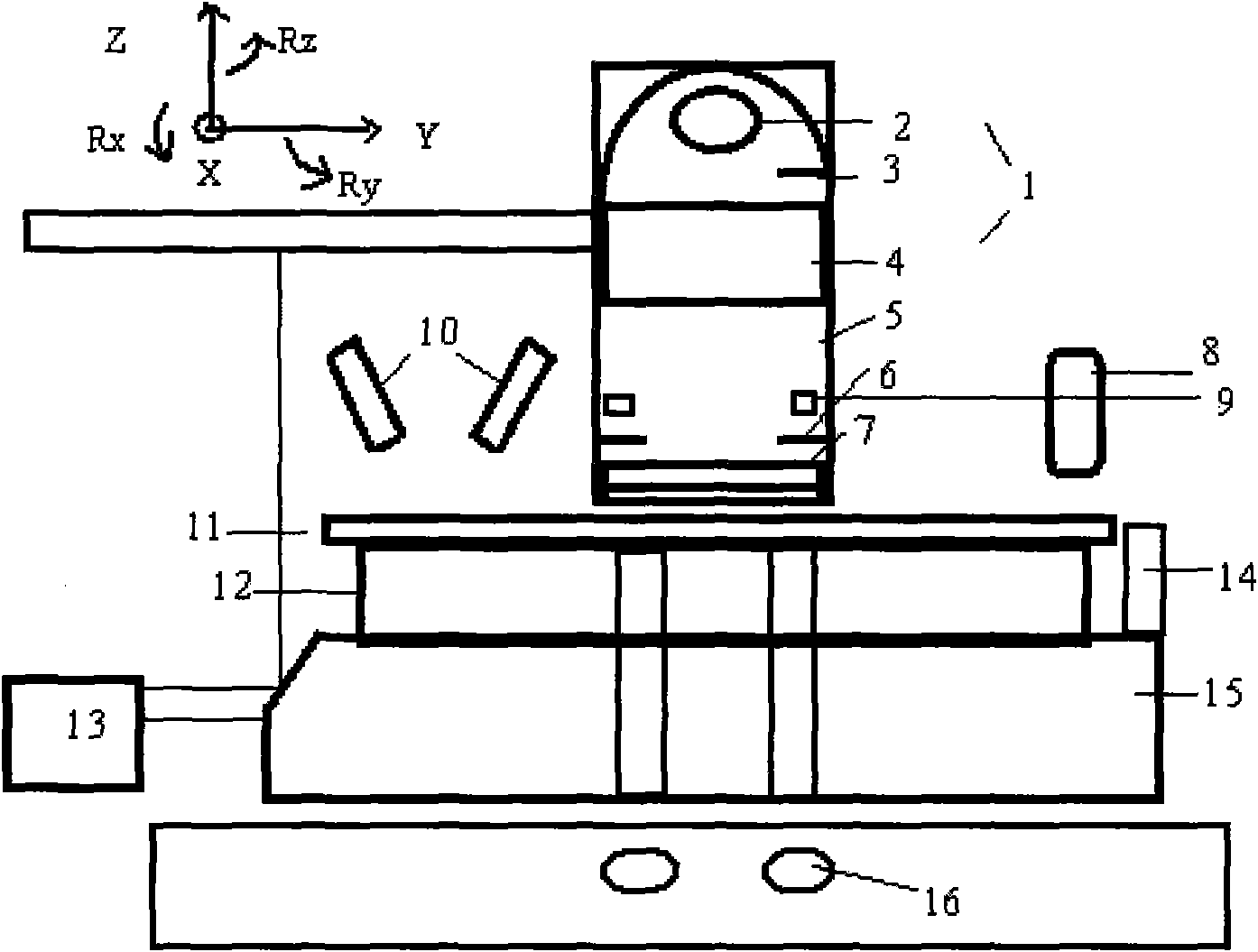

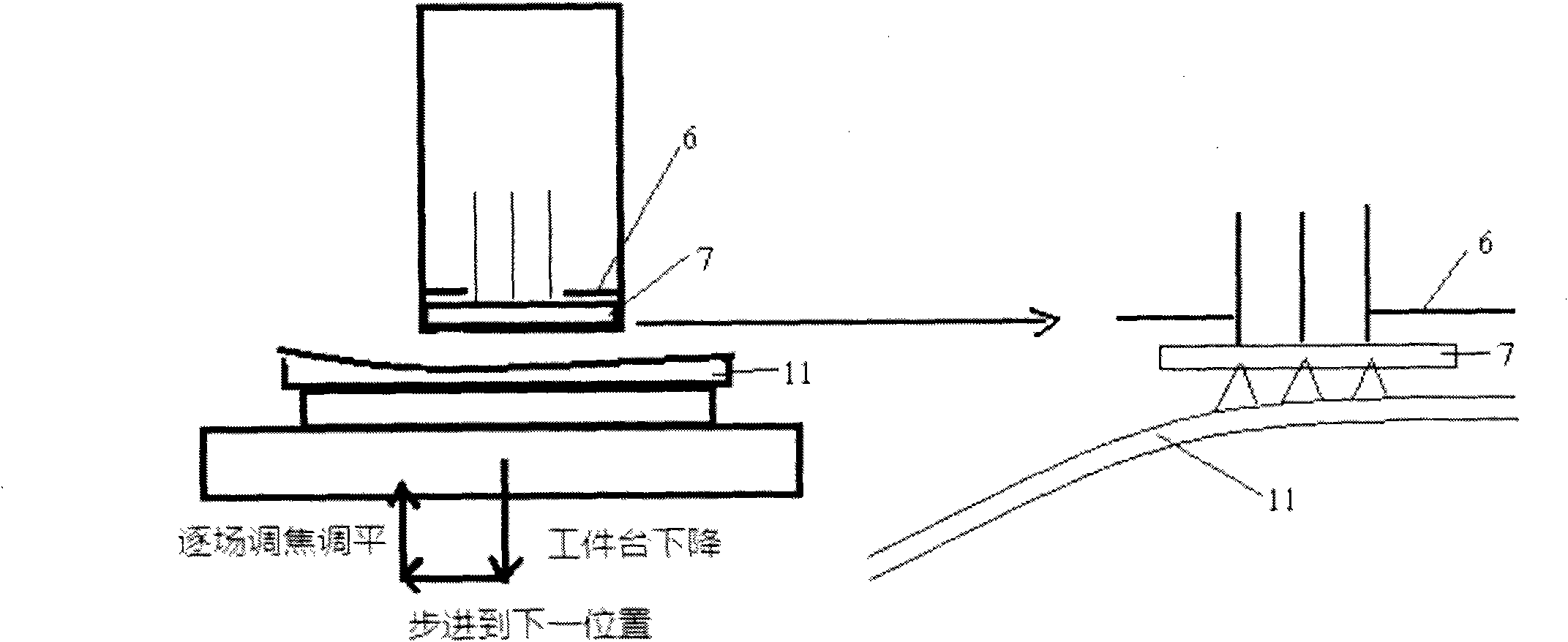

[0037] figure 2 Shown is a schematic structural view of the exposure device according to the present invention. The exposure device according to the present invention includes an illumination subsystem 1 , a workpiece table 15 , a position measurement subsystem 13 , a focusing and leveling subsystem 10 , an alignment subsystem 8 and the like. The lighting subsystem 1 includes a light source 2 and a homogenizer 4. The light source 2 can be a mercury lamp, which provides uniform parallel light illumination for the mask 7 after being converged by a concave mirror and homogenized by the homogenizer 4. The mask 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com