Method for displacement plating of Ni-S alloy barrier layer on copper foil, and chemical passivation method of barrier layer

A technology of chemical passivation and barrier layer, applied in the field of preparation of barrier layer on copper foil, can solve the problems of poor high temperature oxidation resistance, low peeling resistance, complex preparation method of barrier layer, etc. The effect of excellent copper ion migration resistance and excellent ion migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

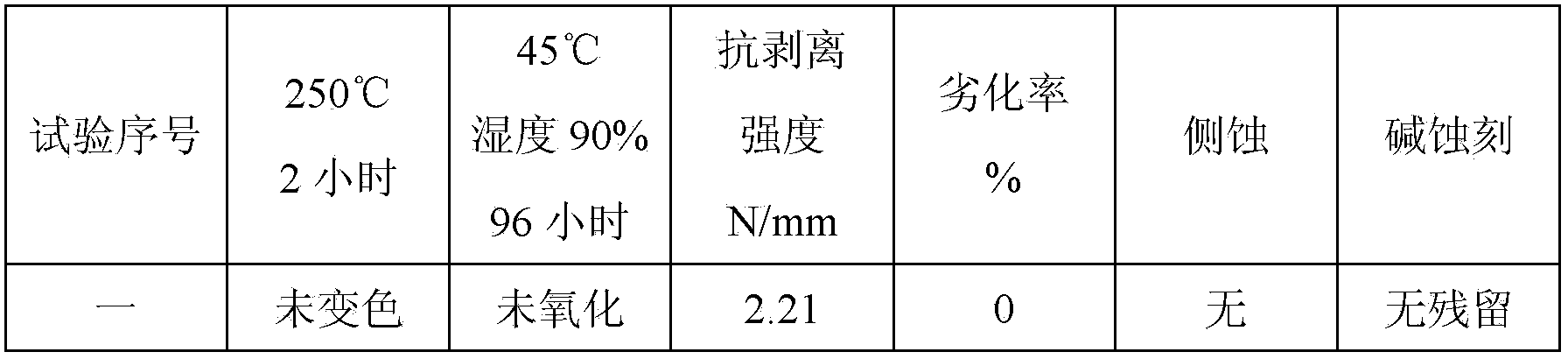

[0028] Embodiment 1: The method for replacing the Ni-S alloy barrier layer on the copper foil of the present embodiment is carried out according to the following steps:

[0029] 1. Preparation of replacement nickel plating: a. The concentration of boric acid is 5-40g / L, the concentration of organic acid or its sodium salt is 0-100g / L, the concentration of sulfur-containing compounds is 7-200g / L, nickel salt The concentration of boric acid, organic acid or its sodium salt, sulfur compound and nickel salt is weighed respectively at 5-150g / L; b, the boric acid weighed in step a is dissolved in deionized water, and then the pH value is pre-adjusted with sulfuric acid to 2.0, to obtain solution A; c, heat the solution A obtained in step b to 50-60°C, then add the sulfur-containing compound weighed in step a, and stir until dissolved to obtain solution B; d, the organic compound weighed in step a Acid or its sodium salt is added to solution B, and the pH value is adjusted to 1.0 to ...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the organic acid described in step one is citric acid, lactic acid, malic acid, gluconic acid, propionic acid, adipic acid, succinic acid, glycine, propanoic acid One or a combination of glutamic acid, glutamic acid, and aspartic acid. Others are the same as in the first embodiment.

[0034] When the organic acid is a composition in this embodiment, each composition is combined in arbitrary ratios.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the concentration of the electrochemical degreasing liquid described in step two is 10~40g / L according to the concentration of sodium carbonate, and the concentration of trisodium phosphate is 10~40g / L, the concentration of sodium silicate is 2~10g / L, and it is prepared by adding sodium carbonate, trisodium phosphate and sodium silicate into water and mixing them evenly. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com