Offshore platform steel with CTOD being greater than or equal to 2 millimeters at minus 40 DEG C and production method thereof

A technology of offshore platform and bainite, which is applied in the field of steel for offshore platforms, can solve the problems of poor steel plate quality, many alloy elements, and lower mechanical properties of steel, so as to ensure service reliability, simple composition and process, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below:

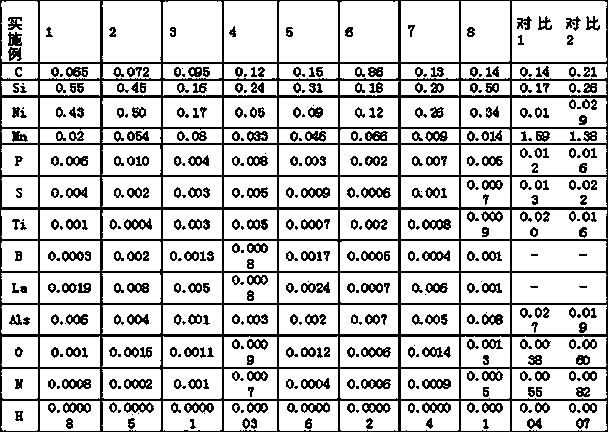

[0039] Table 1 is the component value list of each embodiment of the present invention and comparative example;

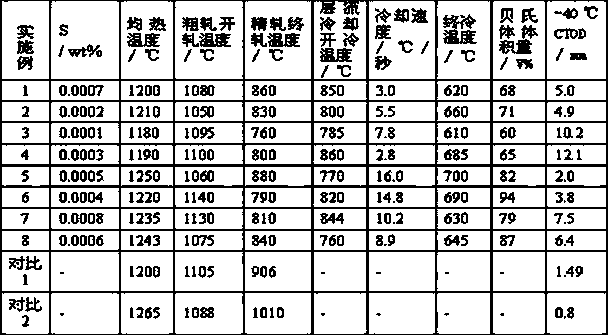

[0040] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0041] Table 3 is a list of test results of the mechanical properties of the various embodiments of the present invention and comparative examples.

[0042] Each embodiment of the present invention is produced according to the following steps:

[0043] Its steps:

[0044] 1) Deep desulfurization of molten iron, control of S in molten iron ≤ 0.0008%;

[0045] 2) Converter smelting;

[0046] 3) Carry out vacuum treatment in the RH furnace, and control the O≤0.0015%, N≤0.001%, H≤0.0001% in the molten iron;

[0047] 4) Continuous casting and heating of the slab, controlling the soaking temperature of the slab at 1180-1250°C;

[0048] 5) Rolling is carried out in sections, the starting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com