Water-soluble fluorescent tracing polymer and its preparation method

A fluorescent polymer, polymer technology, applied in fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of susceptibility to interference, large detection error, high cost, and achieve high detection sensitivity, stable fluorescence performance, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Preparation of fluorescent monomer allyl-7-diethylamino-4-methylcoumarin ammonium bromide

[0040] The preparation reaction (3) is as follows:

[0041]

[0042] (3)

[0043] Put the round bottom flask into an oil bath, add 0.5775g (0.0025mol) of 7-diethylamino-4-methylcoumarin, dissolve it with 10mL of acetonitrile, and add 0.4537g (0.00375mol) of bromopropene dropwise under uniform stirring. mol), condensed and refluxed, the temperature of the oil bath was raised to 80°C, and the reaction was carried out at this temperature for 20 hours. After cooling, distill under reduced pressure, pour the product into ether for recrystallization, then distill under reduced pressure and dry to obtain a white solid product, allyl-7-diethylamino-4-methylcoumarin ammonium bromide, with a yield of 67.3%.

[0044] Using Agilent 6224 mass spectrometer to analyze the obtained fluorescent monomer, it can be seen that the molecular ion peak of the compound (ESI, m / z + ) is 2...

Embodiment 2

[0046] Example 2 Fluorescence Spectrum Test of Fluorescent Monomer

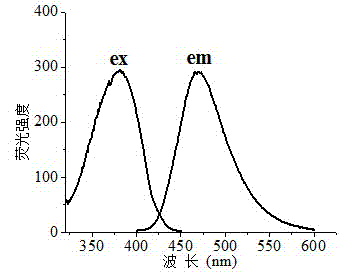

[0047] Weigh allyl-7-diethylamino-4-methylcoumarin ammonium bromide and dissolve it in the produced water of the oil well to make 100 μg / L. The slit width of the fixed fluorescence spectrometer is 10nm to scan the excitation spectrum and emission spectrum respectively. The excitation spectrum and emission spectrum of the fluorescent monomer solution are shown in the appendix figure 1 , the obtained maximum excitation wavelength and maximum emission wavelength are 381nm and 468nm respectively, the maximum emission wavelength is in the blue range of the visible spectrum (435nm-480nm), and has a strong fluorescence intensity.

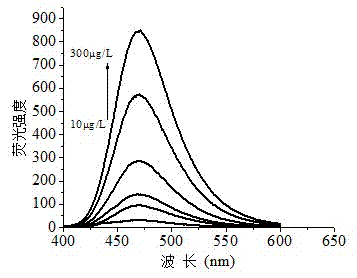

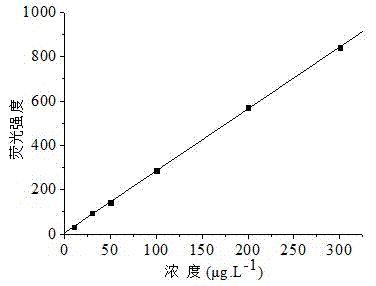

[0048] With a fixed excitation wavelength of 381nm and a slit width of 10 nm, the fluorescence intensity of 10, 30, 50, 100, 200, 300 μg / L fluorescent monomer oilfield produced aqueous solution at 468nm was measured. For the specific fluorescence intensity test results, see the attached...

Embodiment 3

[0049] Example 3 Preparation of Fluorescent Polymer

[0050] The preparation reaction formula (4) is as follows:

[0051]

[0052] (4)

[0053] Add 0.01 g of allyl-7-diethylamino-4-methylcoumarin ammonium bromide, 0.005 g of OP-10 emulsifier and 40 g of deionized water into a 100 mL single-necked bottle equipped with electromagnetic stirring, fully After stirring until the emulsification is complete, add 5.99g of acrylamide, 4.0g of acrylic acid and 2.2222g of sodium hydroxide to make an aqueous solution with a concentration of 20% of the total monomer mass, adjust the pH of the system to 8, and turn on N 2 20 min; then add initiator ammonium persulfate solution and sodium bisulfite solution, the ratio of ammonium persulfate to sodium bisulfite is 1:1, the amount added is 0.5% of the total mass of the monomer, continue Access to N 2 After 20 min, react at a temperature of 50°C for 8h. After the reaction, the polymer is purified with absolute ethanol, the precipitate is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com