Preparation method of TiAl-based laminar composite material plate

A composite material board, composite board technology, applied in metal layered products, chemical instruments and methods, lamination and other directions, can solve the problems of poor tissue uniformity, poor tissue compactness, etc. The effect of internal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

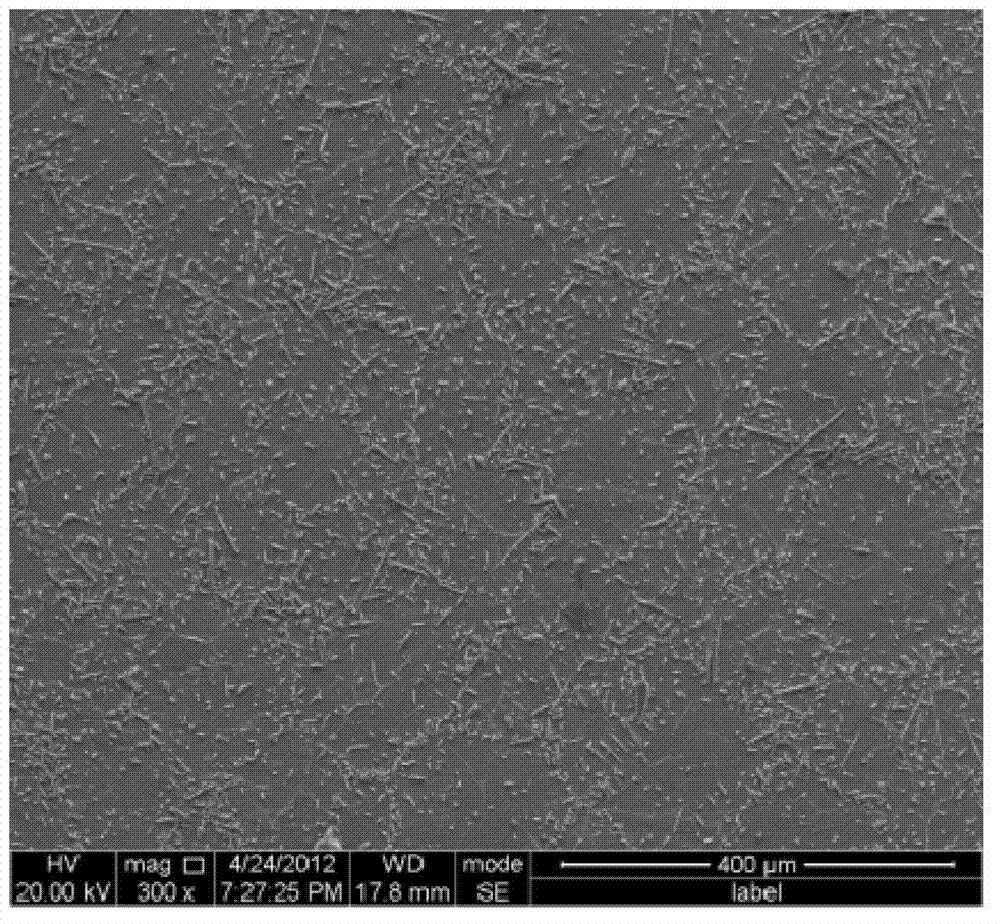

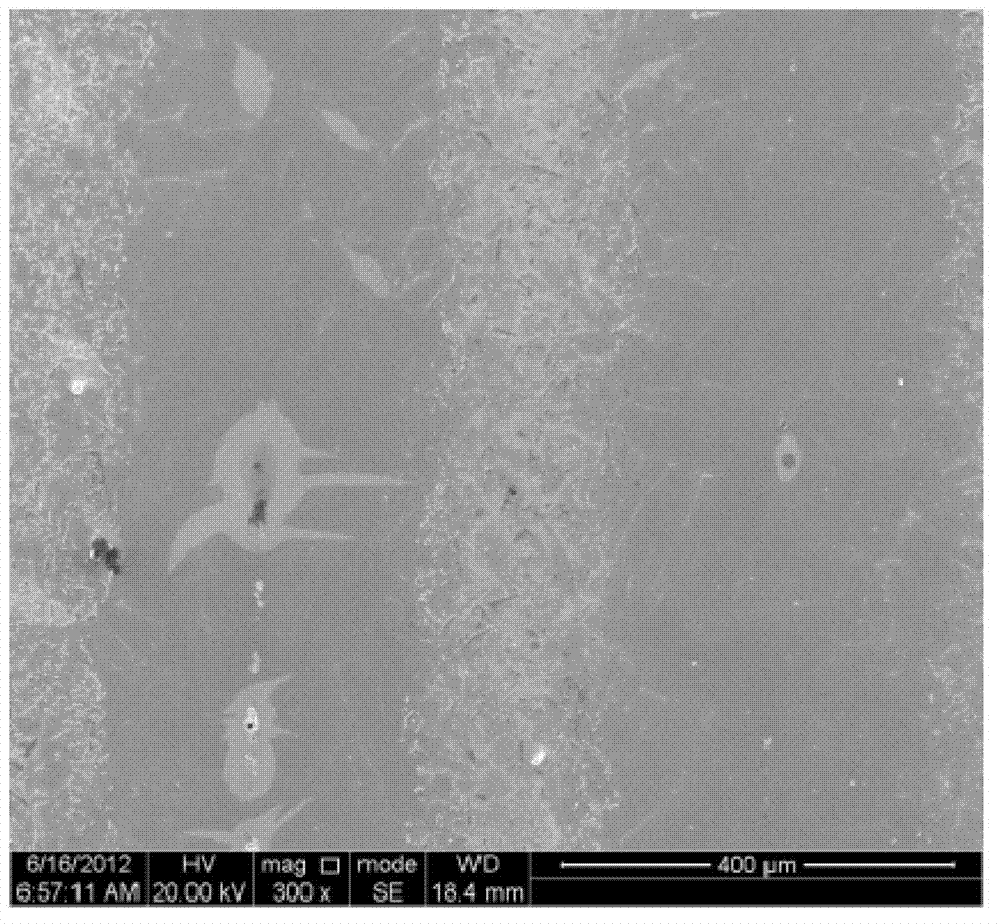

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the preparation method of a kind of TiAl-based composite material plate of this embodiment is carried out according to the following steps:

[0015] 1. The reinforcement and Ti powder are ball milled for 7-10 hours under the condition that the mass ratio of the ball to material is 5:1 and the rotation speed is 180-200rmp to obtain a mixed powder, in which the reinforcement is TiB 2 , the reinforcement accounts for 3% to 5% of the mass of the mixed powder;

[0016] 2. Add the mixed powder obtained in step 1 into the mold, then put the mold in a hot-press furnace, and press it for 1-1.5 hours at a temperature of 1200-1300 ° C and a pressure of 25-30 MPa to obtain a hot-pressed ingot ; Cut the hot-pressed ingot wire into plates, and then obtain the TiB / Ti composite plate after surface pretreatment;

[0017] 3. After the surface pretreatment, the Al plate is alternately stacked with the TiB / Ti composite plate obtained in step 2 and placed in a hot-...

specific Embodiment approach 2

[0019] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the surface pretreatment described in step 2 is: cleaning in 10vol.% HF solution and thinning to the designed thickness, then grinding the surface to remove the knife trace and corroded layer, others are the same as the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the surface pretreatment of the Al plate described in step 3 is as follows: the Al plate is polished with 600-mesh or 800-mesh sandpaper, and then 10wt.% NaOH Alkali washing, others are identical with specific embodiment one or two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com