Artificial knee joint prosthesis

An artificial knee joint and prosthesis technology, applied in the direction of knee joints, elbow joints, joint implants, etc., can solve problems such as abnormal biomechanical properties of the patella, complications of the patellofemoral joint, and affecting postoperative function, and achieve a solution to the problems of the patella The effect of uneven stress distribution, reducing the amount of patella resection, and reducing the incidence of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Artificial knee prosthesis of the present invention (1)

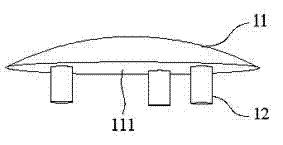

[0033] 1. Patella prosthesis

[0034] Please refer to figure 1 , figure 1 It is a schematic diagram of an artificial knee prosthesis patella prosthesis of the present invention. The patella prosthesis is provided with a top 11 . The top 11 is made of cobalt-chromium-molybdenum alloy (Carpenter Technology Corporation, U.S.), the top 11 is dome-shaped, that is, spherical cone-shaped, the conical surface and the circumference are arc transitions, and the thickness of the top 11 is The diameter of the bottom surface 111 of the top 1 is 28 mm. The bottom surface 111 is provided with three connecting pillars 12, and the three connecting pillars 12 are distributed at vertices of an equilateral triangle. The connecting pillars 12 are cylindrical, with a height of 5 mm and a diameter of 3 mm.

[0035] 2. Femoral prosthesis

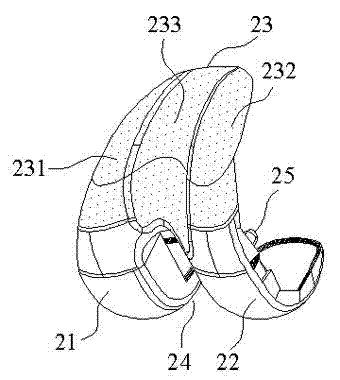

[0036] Please refer to figure 2 , figure 2It is a schematic diagram of...

Embodiment 2

[0038] Example 2 The artificial knee prosthesis of the present invention (2)

[0039] 1. Patella prosthesis

[0040] The patella prosthesis of the present embodiment is basically the same as the patella prosthesis described in embodiment 1, except that the thickness of the top 11 is 3mm, and the diameter of the bottom surface 111 of the top 1 is 32mm; the connecting column 12 is Cylindrical, 6mm high and 3mm in diameter.

[0041] 2. Femoral prosthesis

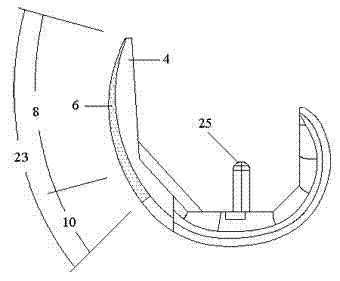

[0042] The shape and position design of the femoral prosthesis is the same as the femoral prosthesis in the prosthesis (Zimmer NexGen LPS-Flex Knee, Cat No: 00596401201) produced by Zimmer Company of the United States, the only difference is that the femoral prosthesis described The trochlear portion 23 is provided with a metal backing 4 and a polyethylene articular surface 6 , that is, the inner trochlear surface 231 , outer trochlear surface 232 and patella groove 233 are all composed of the metal backing 4 and the po...

Embodiment 3

[0043] Example 3 The artificial knee prosthesis of the present invention (3)

[0044] 1. Patella prosthesis

[0045] The patella prosthesis of the present embodiment is basically the same as the patella prosthesis described in embodiment 1, except that the thickness of the top 11 is 4 mm, and the diameter of the bottom surface 111 of the top 1 is 36 mm; the connecting column 12 is Cylindrical, 5mm high, 3mm in diameter.

[0046] 2. Femoral prosthesis

[0047] The shape and position design of the femoral prosthesis is the same as the femoral prosthesis in the prosthesis (P.F.C. Sigma RP System, Cat No: 9068-45-000) produced by Depuy Company in the United States, the only difference is that the femoral prosthesis The trochlear part 23 of the prosthesis is provided with a metal backing 4 and a polyethylene articular surface 6, that is, the inner trochlear surface 231, the outer trochlear surface 232 and the patellar groove 233 are all composed of the metal backing 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com