Solder resist composition and printed wiring board

A technology for printed circuit boards and compositions, which is applied in the directions of printed circuits, printed circuit manufacturing, and secondary treatment of printed circuits, etc. It can solve the problems of reduced reflectivity, insufficient absorption, and difficulty in forming high-definition pattern latent images, and achieves Effect of increasing illuminance and suppressing decrease in reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

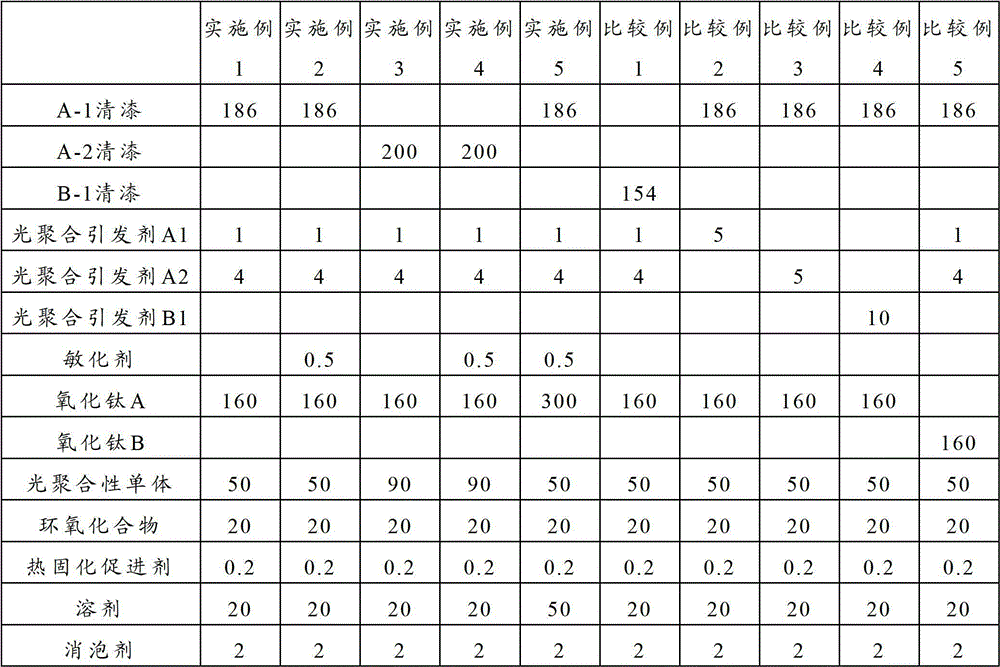

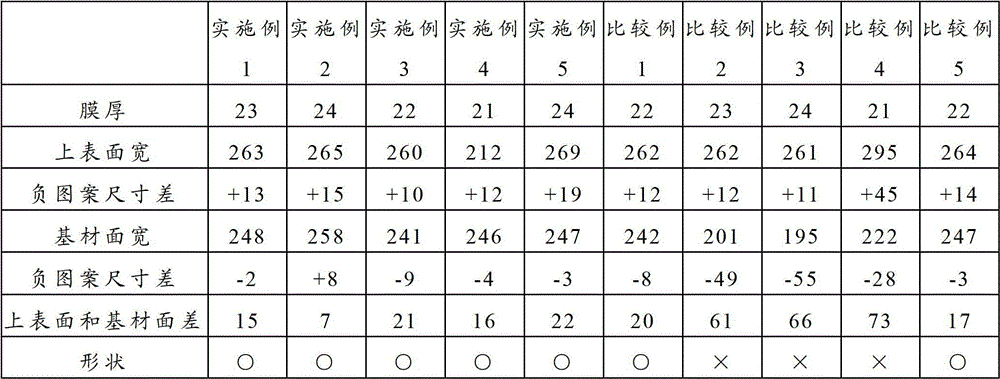

[0077] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated concretely, this invention is not limited to a following example.

[0078] (A) Synthesis of carboxyl-containing resin without aromatic ring

Synthetic example 1

[0080] In a 2-liter separable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube, 900 g of diglyme as a solvent and 21.4 g of peroxide (2 -Ethylhexanoic acid) tert-butyl (manufactured by NOF Corporation, trade name: PERBUTYL O), heated to 90°C. After heating, 309.9 g of methacrylic acid, 116.4 g of methyl methacrylate, and 109.8 g of lactone-modified 2-hydroxyethyl methacrylate (manufactured by Daicel Chemical Industries, Ltd., trade name: PLACCEL FM1), 21.4 g of bis(4-tert-butylcyclohexyl) peroxydicarbonate (manufactured by NOF Corporation, trade name: PERBUTYL TCP) as a polymerization initiator. Furthermore, this was aged for 6 hours to obtain a carboxyl group-containing copolymer resin. In addition, the above reaction was carried out under a nitrogen atmosphere.

[0081] Next, 363.9 g of 3,4-epoxycyclohexyl methacrylate (manufactured by Daicel Chemical Industries, Ltd., trade name: Cyclomer A200) and 3.6 g...

Synthetic example 2

[0083] In a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux condenser, add diethylene glycol monoethyl ether acetate as a solvent, and azobisisobutyronitrile as a catalyst, and heat it to 80 °C under a nitrogen atmosphere. °C, a monomer obtained by mixing methacrylic acid and methyl methacrylate in a molar ratio of 0.40:0.60 was added dropwise over 2 hours. Furthermore, after stirring this for 1 hour, it heated up to 115 degreeC, made it deactivate, and obtained the resin solution.

[0084] After the resin solution is cooled, using tetrabutylammonium bromide as a catalyst, under the condition of 95-105°C and 30 hours, butyl glycidyl ether and the equivalent carboxyl group of the obtained resin are reacted at a molar ratio of 0.40. Addition reaction and cooling.

[0085] Furthermore, tetrahydrophthalic anhydride and the OH group of the resin obtained above were added-reacted at the molar ratio of 0.26 under the conditions of 95-105 degreeC, and 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com