High-temperature-resistant anticorrosive paint and preparation method thereof

An anti-corrosion coating and high temperature resistance technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of poor secondary film forming performance, poor high temperature resistance, affecting product quality, etc., and achieve good weather resistance, Good interoperability and improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of high temperature resistant anticorrosion coating, comprising the steps of:

[0032] Preparation of topcoat: Take 20g polyester modified silicone resin (Guangzhou Liuping Chemical Co., Ltd., model 8810A), 1g additive dimethyl siloxane, 25g xylene, 15g butyl ester, 10g propylene glycol methyl ether acetate Ester, 8.05g of glass powder, 11.6g of talc powder, 4.35g of mica powder, and 5g of carbon black were put into operation kettle A, and dispersed at 500RPM for 70min. According to the mass percentage of raw materials in the diluent, xylene is 50%, butyl ester is 30%, and propylene glycol methyl ether acetate is 20%. According to the mass percentage of raw materials, 20% of polyester modified silicone resin, 29% of filler, 50% of diluent, and 1% of auxiliary agent.

[0033] Preparation of primer: Take 15g epoxy modified silicone resin (produced by Hubei Sihai Chemical Co., Ltd., model SH-023), 10g phenolic resin (phenolic resin 2130), 1g additive ...

Embodiment 2

[0044] The preparation steps of the high temperature resistant anti-corrosion paint of this embodiment are as embodiment 1, wherein the raw material formula of topcoat and primer is as follows:

[0045] Topcoat: Primer:

[0046] Polyester modified silicone resin: 20g Epoxy modified silicone resin: 13g

[0047] Polymethylphenylsiloxane: 1g Phenolic resin: 12g

[0048] Xylene: 5g Polymethylphenylsiloxane: 0.8g

[0049] Butyl ester: 25g Xylene: 3.42g

[0050] Propylene glycol methyl ether acetate: 20g Butyl ester: 14.78g

[0051] Glass powder: 8.7g Propylene glycol methyl ether acetate: 16g

[0052] Talc powder: 8.7g Glass powder: 12g

[0053] Mica powder: 8.7g Talc powder: 12g

[0054] Carbon black: 2.9g Mica powder: 12g

[0055] Aluminum tripolyphosphate: 4g

[0056] During the preparation, in the preparation of the topcoat, after adding the raw materials into the operation kettle A, disperse at 1000RPM for 40min. In the configura...

Embodiment 3

[0067] The preparation steps of the high temperature resistant anti-corrosion paint of this embodiment are as embodiment 1, wherein the raw material formula of topcoat and primer is as follows:

[0068] Topcoat: Primer:

[0069] Polyester modified silicone resin: 20g Epoxy modified silicone resin: 10g

[0070] Polymethylphenylsiloxane: 1g Phenolic resin: 15g

[0071] Xylene: 5g Polymethylphenylsiloxane: 0.5g

[0072] Butyl ester: 15g Xylene: 17.25g

[0073] Propylene glycol methyl ether acetate: 30g Butyl ester: 10.35g

[0074] Glass powder: 2.9g Propylene glycol methyl ether acetate: 6.9g

[0075] Talc powder: 11.6g Glass powder: 11g

[0076] Mica powder: 8.7g Talc powder: 16g

[0077] Carbon black: 5.8g Mica powder: 6g

[0078] Aluminum tripolyphosphate: 7g

[0079] During the preparation, in the preparation of the topcoat, after adding the raw materials into the operation kettle A, disperse at 600RPM for 50min. In the configura...

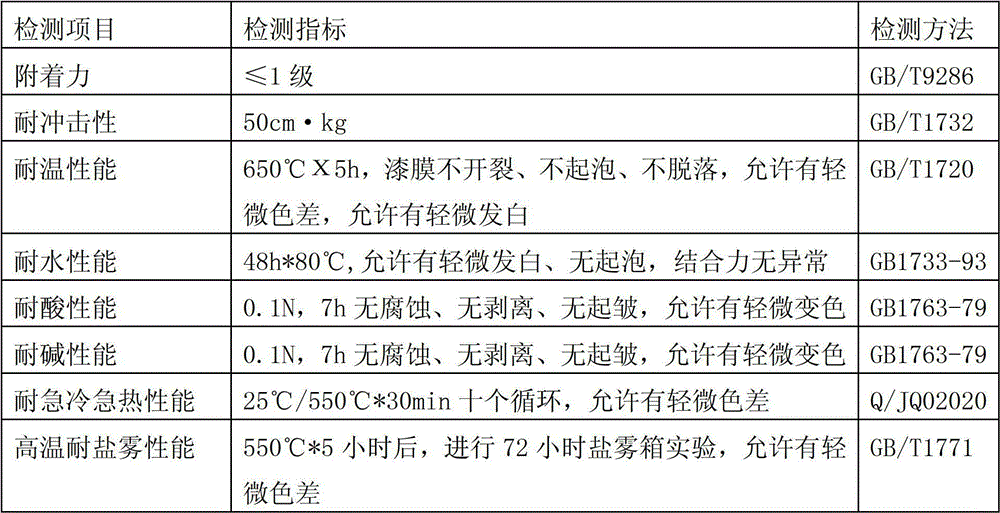

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com