Thermal insulation anti-corrosive high pressure bearing special steel-plastic composite pipe

A steel-plastic pipe and high-pressure technology, which is applied in the direction of heat preservation and protection of pipes and pipes through heat insulation, can solve the problems of inability to meet the working environment requirements of the working face, flame retardancy and antistatic, and inability to effectively solve heat damage, etc. problems, to achieve the effect of inhibiting heat conduction, inhibiting heat radiation and heat loss, and beautifying the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

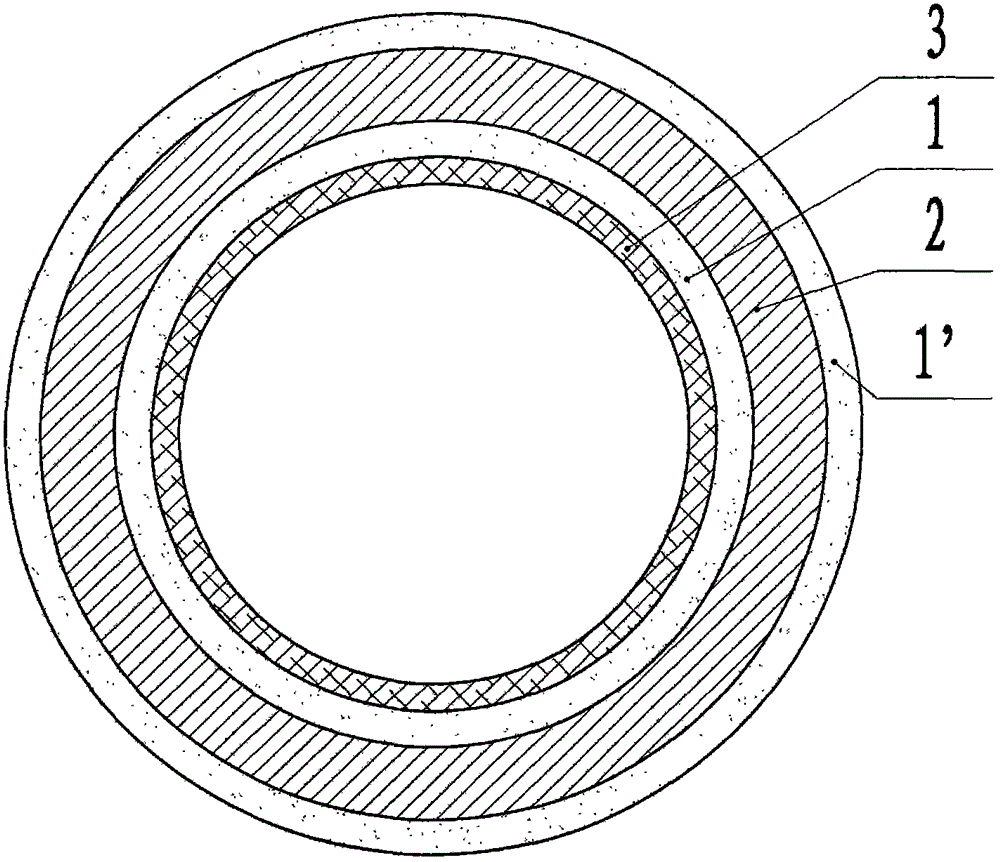

Embodiment 1

[0051] see structural representation figure 1, the steel pipe 2 as the base pipe is firstly derusted by shot blasting or pickling and phosphating, and then the steel pipe 2 is subjected to online plastic spraying or dipping treatment, that is, the inner and outer wall surfaces of the steel pipe 2 are coated with the inner plastic layer 1 and the outer surface. The plastic coating layer 1', the inner plastic coating layer 1 and the outer plastic coating layer 1' are polyethylene coating or epoxy resin coating; the inner wall surface of the inner plastic coating layer 1 is also coated with an inner thermal insulation coating 3.

[0052] The thickness of the polyethylene coating or epoxy resin coating is 0.3-0.5 mm, preferably 0.4 mm.

[0053] Coat the inner wall of the inner plastic layer 1 of the pipe with a thermal insulation coating by a spraying machine and a spray gun to form an inner thermal insulation coating 3. The thickness of the inner thermal insulation coating 3 is ...

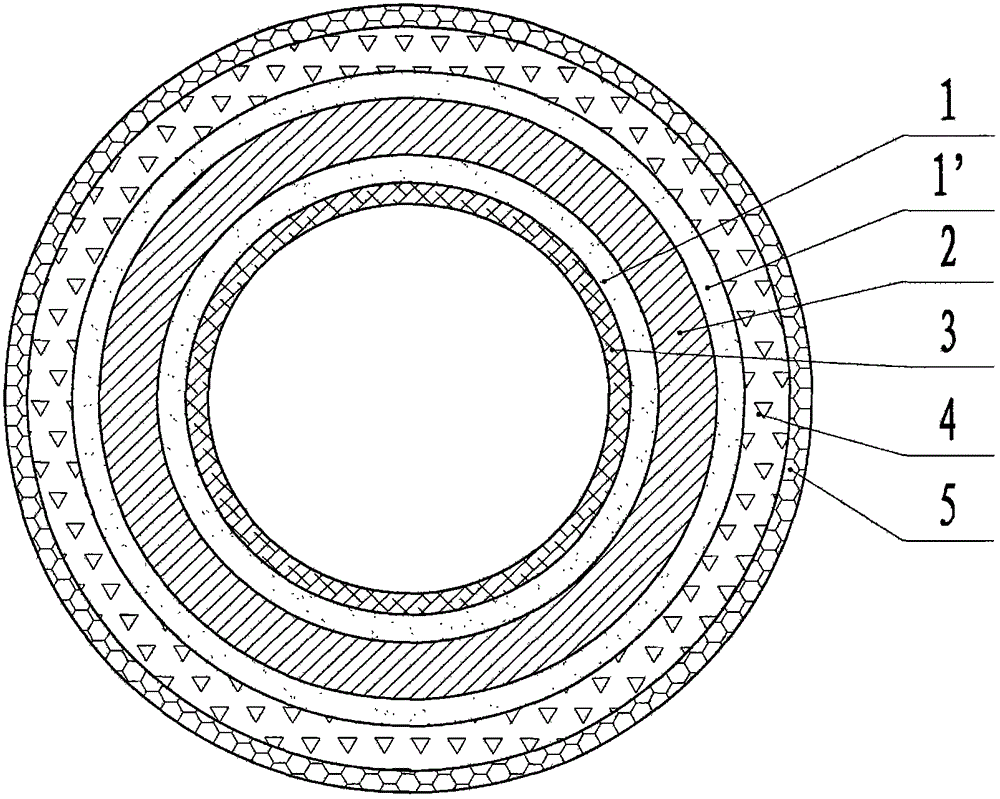

Embodiment 2

[0056] see structural representation figure 2 In this embodiment, on the basis of Embodiment 1, the outer wall surface of the outer plastic coating layer 1' is covered with a silica nano-airgel felt layer 4, and the outer wall surface of the silica nano-airgel felt layer 4 is coated with a poly Vinyl cover5.

[0057] Using silica nano-airgel felt, its thermal insulation performance is better than that of a simple thermal insulation coating, and the combined use of the two improves the effect more significantly. In addition, silica airgel felt is flexible, environmentally friendly, and can be flexibly constructed, and has extremely high porosity, extremely low density, large surface area, extremely low thermal conductivity, non-flammable, non-toxic, environmentally friendly, light weight, and good sound absorption and shock absorption. performance.

[0058] Silica nano-airgel felt layer 4 is to wrap the silica nano-airgel felt that has been divided in advance on the outer wa...

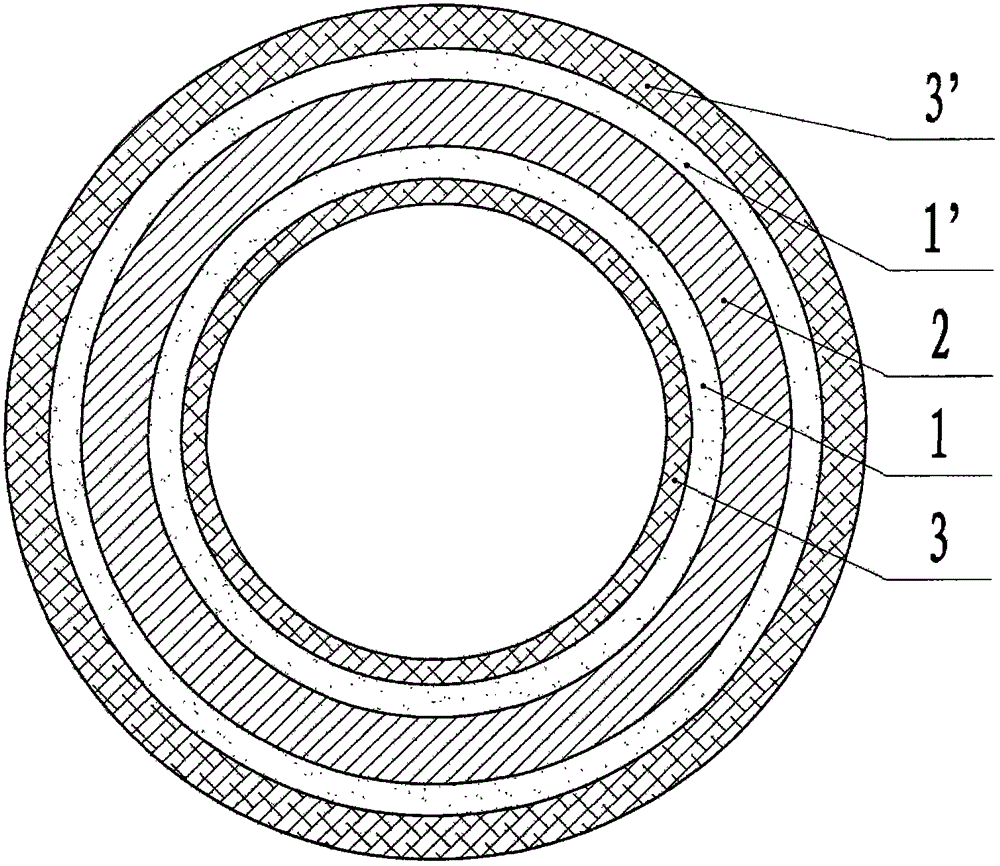

Embodiment 3

[0061] see structural representation image 3 , on the basis of Embodiment 1, the outer wall surface of the outer plastic coating layer 1' of the pipe is also coated with a thermal insulation coating, that is, an outer thermal insulation coating 3 ', and the outer thermal insulation coating 3 ' is compatible with the inner thermal insulation coating Coating 3 had the same paint composition and thickness.

[0062] In this embodiment, on the basis of the first embodiment, heat preservation is performed on the inner and outer walls of the pipe at the same time, which can better heat and insulate the medium transported by the pipeline.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com