Ternary boride ceramic coating with cerium oxide and preparation method thereof

A ternary boride, ceramic coating technology, applied in coating, metal material coating process, fusion spraying and other directions, can solve the problems of high friction factor, inability to form boundary film, low density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

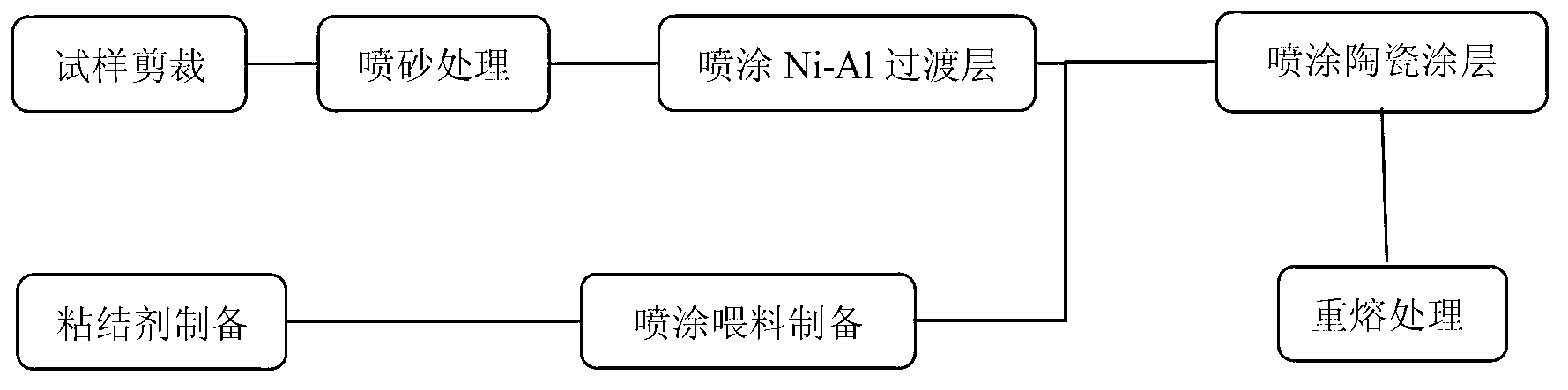

[0022] The invention provides a method for preparing a ternary boride ceramic coating containing cerium oxide, the process flow is as follows figure 1 As shown, it mainly includes three parts: substrate sample pretreatment, spray feeding preparation and ceramic coating preparation, as follows:

[0023] The first step, substrate pretreatment:

[0024] (1) Surface roughening of the sample:

[0025] The base material is Q235 steel plate, and the chemical composition is shown in Table 1:

[0026] Table 1Q235-A steel plate chemical composition (wt.%)

[0027]

[0028] The Q235 steel plate with a thickness of 6mm is cut into a sample with an area of 25mm×25mm by wire cutting, and the surface is sandblasted to remove the surface scale, so that the surface of the sample is activated and roughened, so as to increase the contact area between the workpiece and the sprayed layer , and the coarsening of the coating can change the residual stress of the coating, which is conducive t...

Embodiment 1

[0043] The preparation method provided by the invention is used to prepare a ternary boride ceramic coating containing cerium oxide, and 1% by mass of cerium oxide is added to the spray powder. The steps of the preparation method are as follows:

[0044] The first step, substrate pretreatment:

[0045] The surface of the substrate is roughened, and then a Ni-Al transition layer is prepared on it.

[0046] The substrate is made of Q235 steel plate, and the surface is roughened by sandblasting. The sandblasting process parameters are as follows: the sandblasting abrasive grain is 20 mesh corundum sand, the spraying distance is 150mm, the sandblasting angle is 90°, and the compressed air pressure is 0.8MPa.

[0047] Before preparing the transition layer, the substrate can be preheated, the preheating temperature is 300° C., and the preheating time is 7 minutes. Nickel-coated aluminum powder is used for the preparation of the transition layer.

[0048] The second step, the prepa...

Embodiment 2

[0054] The ternary boride ceramic coating containing cerium oxide is prepared by the preparation method provided by the invention, and 2% cerium oxide is added in the spray powder, and the steps of the preparation method are as follows:

[0055] The first step, substrate pretreatment:

[0056] The surface of the base Q235 steel is roughened, and then a Ni-Al transition layer is prepared on it.

[0057] The surface roughening of the base body adopts sandblasting method, and the sandblasting process parameters are as follows: the sandblasting abrasive grain is 20 mesh corundum sand, the spraying distance is 100mm, the sandblasting angle is 90°, and the compressed air pressure is 0.6MPa.

[0058] Before preparing the transition layer, the substrate can be preheated, the preheating temperature is 400° C., and the preheating time is 5 minutes.

[0059] The second step, the preparation of spray feed:

[0060] Select 32g, 48g, and 20g of Mo powder, FeB alloy powder, and Fe powder, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com