Method for preparing iron powder and recovering nonferrous metal from blast furnace iron making smoke dust

A non-ferrous metal, blast furnace ironmaking technology, applied in the direction of improving process efficiency, etc., to achieve the effects of simple process, mature and reliable, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

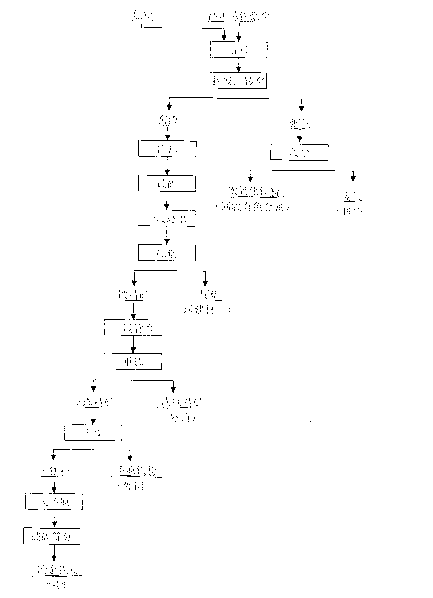

Image

Examples

Embodiment Construction

[0018] A kind of blast furnace ironmaking dust is used, its chemical composition is (Wt%): Fe24, Zn9.0, Pb1.0, Cl1.2, C6.0, moisture 18, the treatment process consists of the following sections:

[0019] (1) Reduction and volatilization of the rotary kiln: the raw material blast furnace ironmaking fume is mixed with 20-25% coke powder (mass ratio), and put into a φ1.7m×32m volatilization rotary kiln. Control the rotation speed of the rotary kiln to 0.5-2rpm, and control the roasting temperature to 1050-1150°C to produce flue gas and kiln slag. The daily processing capacity of the kiln can reach 100t (wet basis).

[0020] (2) Rotary kiln flue gas dust collection: the flue gas produced by the rotary kiln enters the bag filter after passing through the settling chamber and the surface cooler, and the collected output product is secondary zinc oxide powder, and its main components are (Wt%): Zn50, Pb7.0, In0.06, Fe1.5, Cl6.0.

[0021] (3) Crushing and grinding of kiln slag: the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com